Electronic control grease separation system

A technology of grease separation and electric control, which is applied in the field of electric control grease separation system and the follow-up treatment of waste oil-water mixture, which can solve the problems of high transportation cost, environmental pollution, difficult disposal, etc., and achieve reduced environmental pollution, good quality, and reduced emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

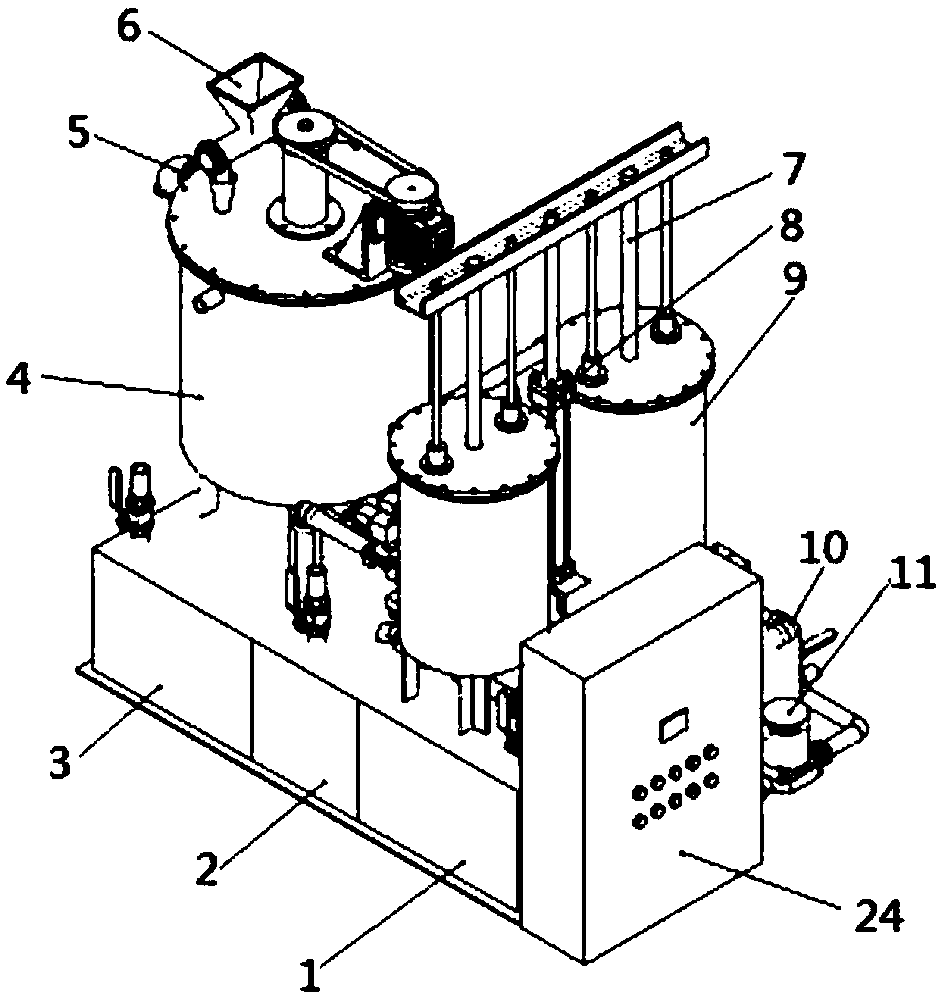

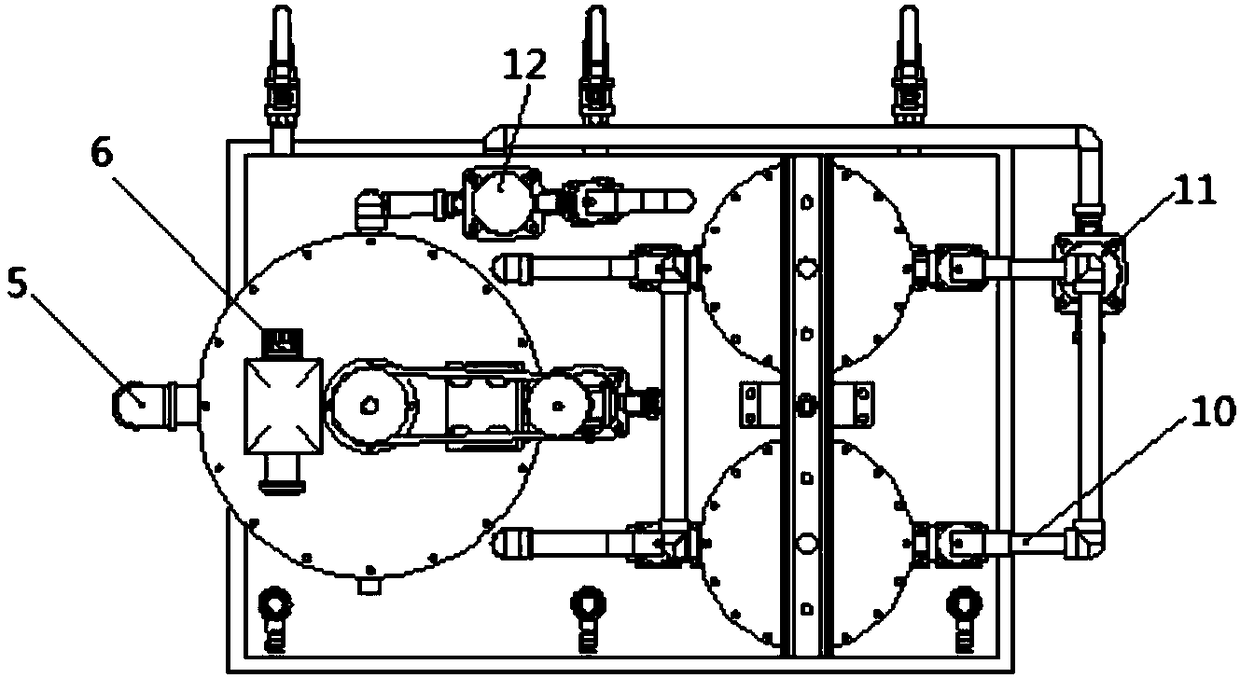

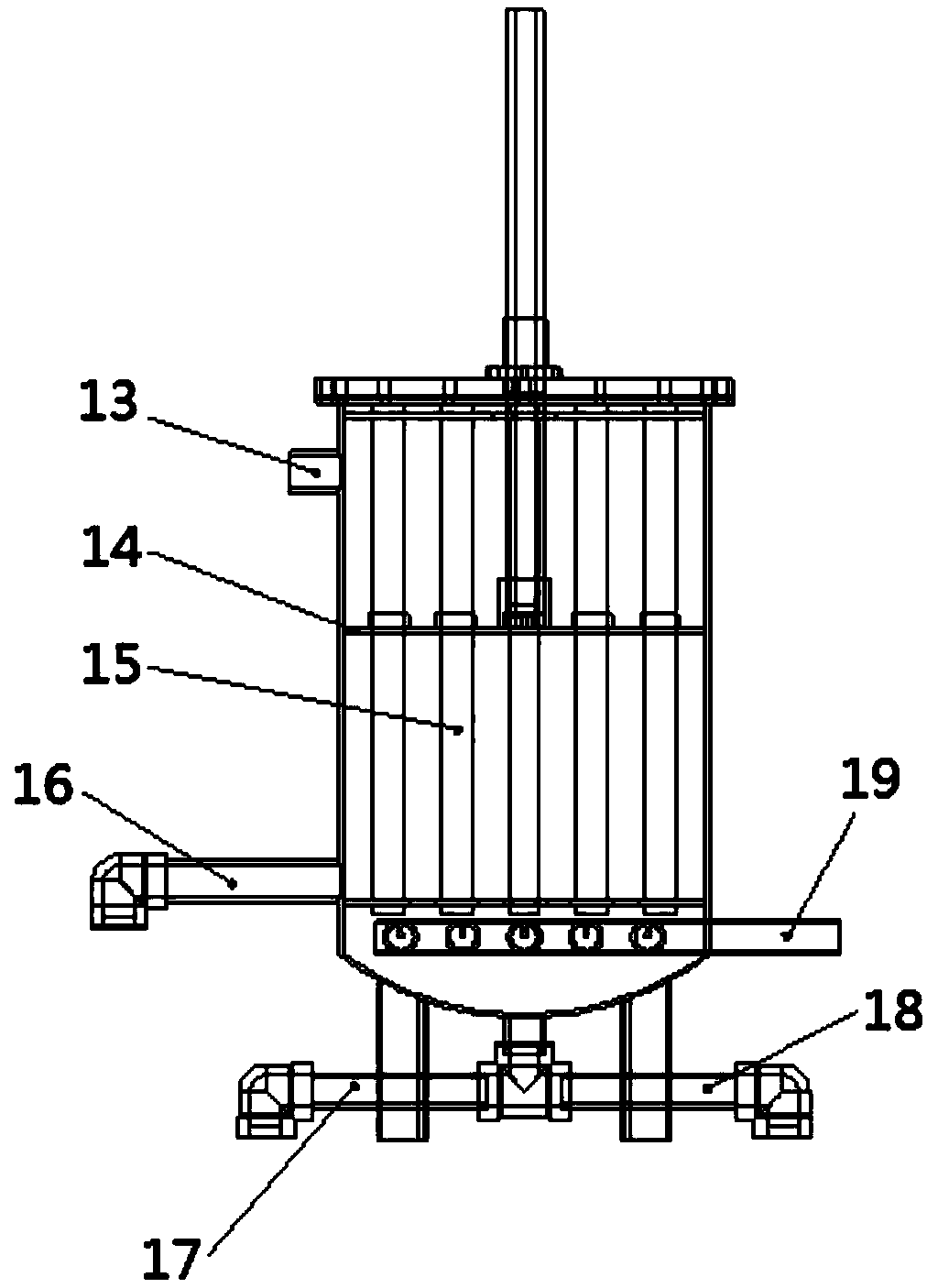

[0032] Embodiment 1: see figure 1 , figure 2 , image 3 , Figure 4 , an electronically controlled grease separation system, comprising a stirring tank 4, an automatic powder feeding device and a magnetic separation tank 9, the stirring tank is provided with a liquid inlet 5 and a magnetic powder inlet 6, and the magnetic powder inlet 6 and the automatic powder feeding device The upper and lower ends of the stirring tank communicate with the magnetic separation tank 9 through the delivery pipeline 23 .

[0033] The stirring tank is provided with a stirring shaft, and the stirring tank 4 is provided with a motor and a belt pulley to drive the stirring shaft to rotate at a high speed. The stirring shaft is equipped with four stages of shear discs 21, and the first three stages are blade-type structures. It is mainly used to cut and emulsify particles and grease; the fourth stage at the bottom is the fan disc 22, which is mainly used to stir the liquid evenly. After sufficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com