Oil removing pretreatment technology for petroleum oil refining wastewater

A technology for oil refinery sewage and pretreatment, applied in the field of water treatment, can solve the problems of resource waste, increase the cost and time of subsequent processes, and oil cannot be recovered, and achieve the effects of scientific device structure, considerable economic benefits, and improved oil removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

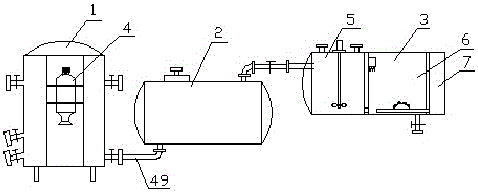

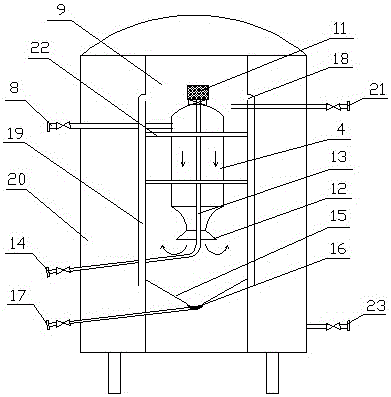

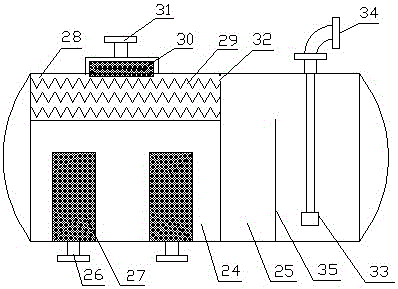

[0039] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

[0040] The present invention mainly pretreats the oily sewage discharged from refining and chemical equipment, controls the oil content in the sewage below 20 mg / L, and can directly enter the subsequent biochemical treatment process section, which can reduce the treatment cost and time of the subsequent process, reduce cost and improve efficiency.

[0041] A kind of oil refine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com