High-efficiency dissolved air flotation system

A dissolved air flotation and high-efficiency technology, applied in the field of air flotation systems, can solve problems such as complex operation and management, unstable bubble effect, and limited number of bubbles, and achieve the effects of reduced operating costs, convenient remote monitoring, and high bubble density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

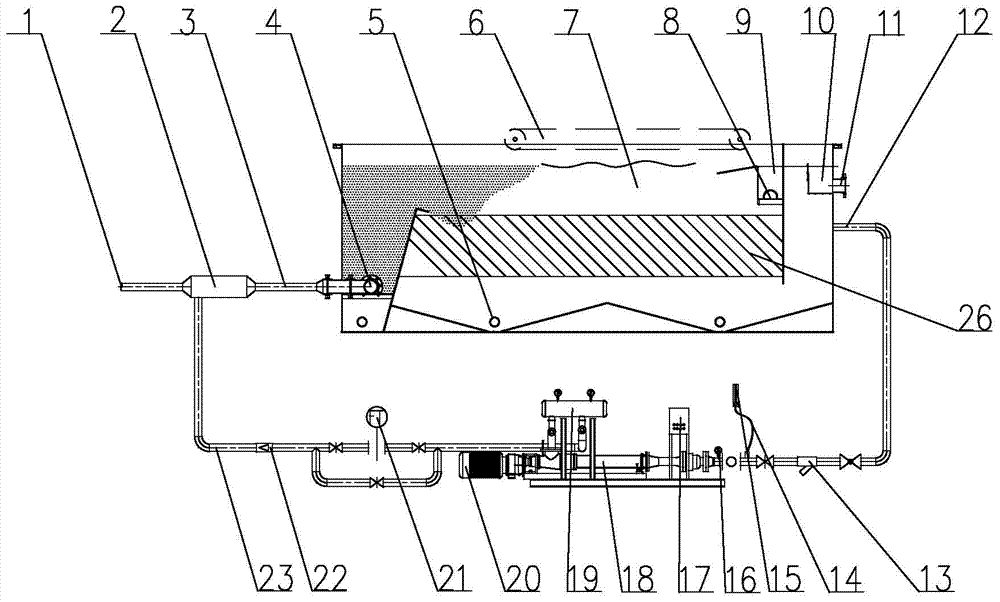

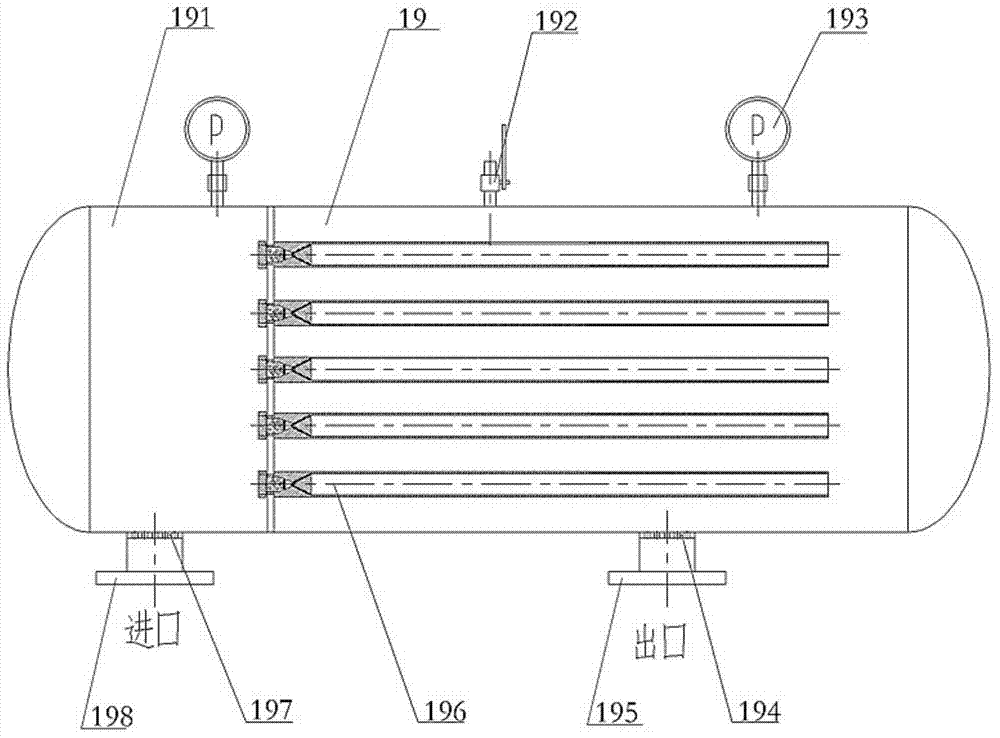

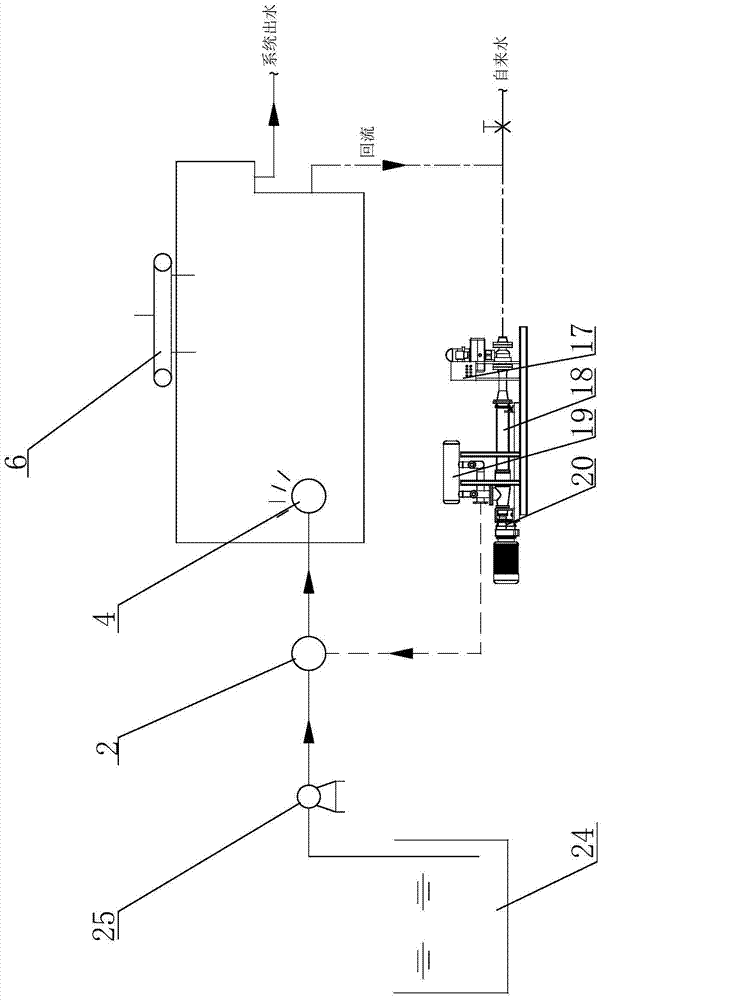

[0030] See figure 1 , is a structural schematic diagram of the present invention, a high-efficiency dissolved air flotation system of the present invention, including an air flotation tank 7, a slag scraper 6 installed in the air flotation tank 7, a slag discharge device and a water outlet device, and the air flotation tank drawn from the end of the air flotation tank 7 The gas-liquid mixing pump inlet pipe 12 is provided with an inlet pipe 14, and is connected to the gas-liquid mixing pump 20, the microbubble generator 19 through the gas-liquid mixing pipe 18, and the high-pressure saturated gas-dissolved water pipe 23 drawn from the microbubble generator 19 The dissolved air releaser 4 at the end of the water inlet pipe 3 of the air flotation tank is connected with the external sewage inlet pipe 1 through the T-shaped mixer 2 .

[0031] The air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com