Method for preparing large-area graphene paper by utilizing hydroiodic acid

A technology of graphene paper and hydroiodic acid, which is applied in the field of material science, can solve the problems of difficulty in obtaining large-area graphene paper, limiting the wide application of graphene paper, and high cost, and achieves simple and rapid preparation, low cost, and wide application value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

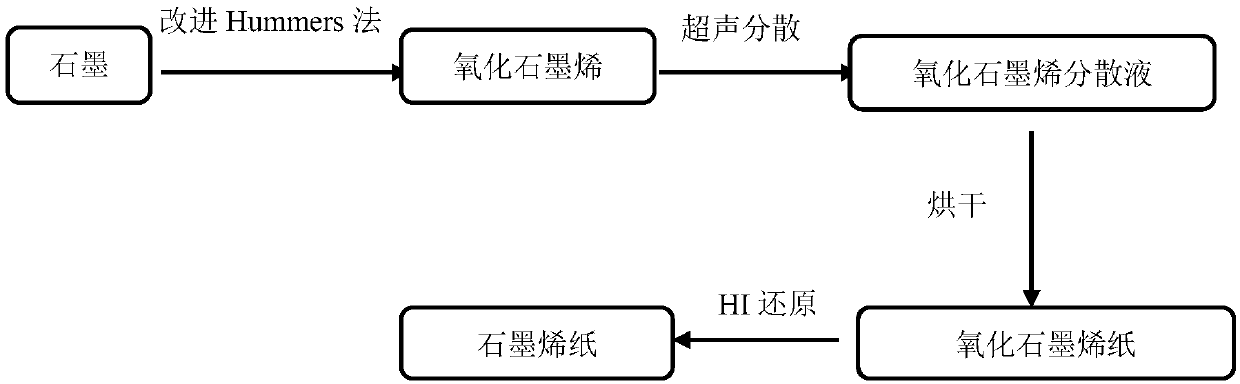

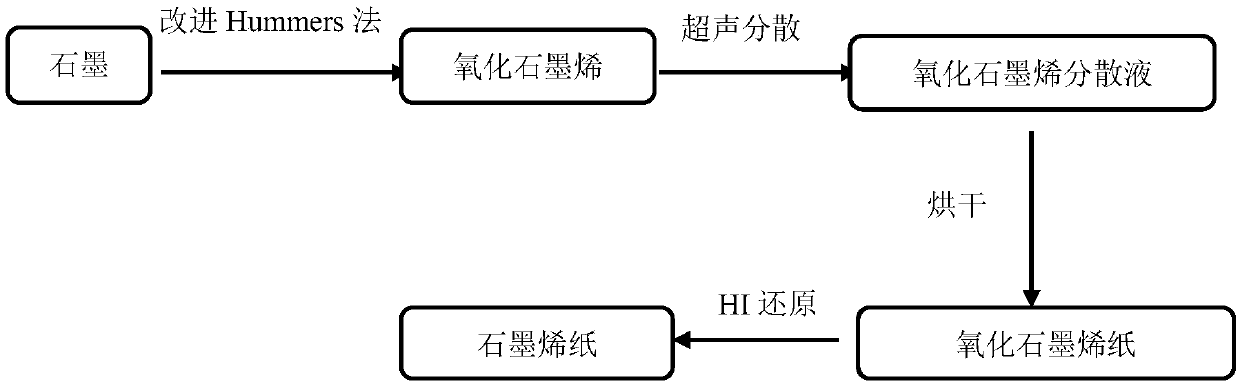

Method used

Image

Examples

Embodiment 1

[0031] 1) Preparation of graphene oxide using an improved Hummers method:

[0032] Step 1. Add 20ml of concentrated sulfuric acid (98wt%) to a 1L three-necked flask and stir for 5min under ice-water bath conditions;

[0033] Step 2: Add 1g graphite slowly to the concentrated sulfuric acid solution;

[0034] Step 3: Add 0.5 g of sodium nitrate to the above mixed solution and react for 10 minutes;

[0035] Step 4. Add 3g of potassium permanganate slowly and stir for 90min, observe the color change from purple to dark green;

[0036] Step 5. Increase the temperature, the temperature of the water bath is 35°C, react for 40 minutes, and observe the color change from dark green to brown;

[0037] Step 6. Add 46ml of deionized water, add dropwise, then heat to 98°C and stir for 40min;

[0038] Step 7. Add 13ml hydrogen peroxide dropwise and stir for 15min;

[0039] Step 8. After the reaction, wait for the solution to cool, add deionized water, stand still, and remove the supernatant liquid;

[004...

Embodiment 2

[0051] 1) Preparation of graphene oxide using an improved Hummers method:

[0052] Step 1. Add 23ml of concentrated sulfuric acid (98wt%) to a 1L three-necked flask and stir for 5min under ice-water bath conditions;

[0053] Step 2: Add 1g graphite slowly to the concentrated sulfuric acid solution;

[0054] Step 3: Add 0.5 g of sodium nitrate to the above mixed solution and react for 10 minutes;

[0055] Step 4. Add 3g potassium permanganate slowly and slowly and stir for 93min, and observe the color change from purple to dark green;

[0056] Step 5: Increase the temperature, the temperature of the water bath is about 36°C, react for 45 minutes, and observe that the color changes from dark green to brown;

[0057] Step 6. Add 46ml of deionized water, add dropwise, then heat to 98°C and stir for 40min;

[0058] Step 7. Add 15ml hydrogen peroxide dropwise and stir for 20min;

[0059] Step 8. After the reaction, wait for the solution to cool, add deionized water, stand still, and remove the s...

Embodiment 3

[0071] 1) Preparation of graphene oxide using an improved Hummers method:

[0072] Step 1. Add 25ml of concentrated sulfuric acid (98wt%) to a 1L three-necked flask and stir for 5min under ice-water bath conditions;

[0073] Step 2: Add 1g graphite slowly to the concentrated sulfuric acid solution;

[0074] Step 3: Add 0.5 g of sodium nitrate to the above mixed solution and react for 10 minutes;

[0075] Step 4. Add 3 g of potassium permanganate slowly and stir for 96 minutes, and observe that the color changes from purple to dark green;

[0076] Step 5: Raise the temperature, the temperature of the water bath is about 38°C, react for 53 minutes, and observe that the color changes from dark green to brown;

[0077] Step 6. Add 46ml of deionized water, add dropwise, then heat to 98°C and stir for 40min;

[0078] Step 7. Add 17ml hydrogen peroxide dropwise and stir for 15min;

[0079] Step 8. After the reaction, wait for the solution to cool, add deionized water, stand still, and remove the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com