Method for ore dressing and desilicating mixed type bauxite

A bauxite and mixed technology, applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problems of separation of aluminum minerals and silicon minerals, fine grinding products, and great difficulty, so as to expand resources The effect of supply, high recovery rate, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

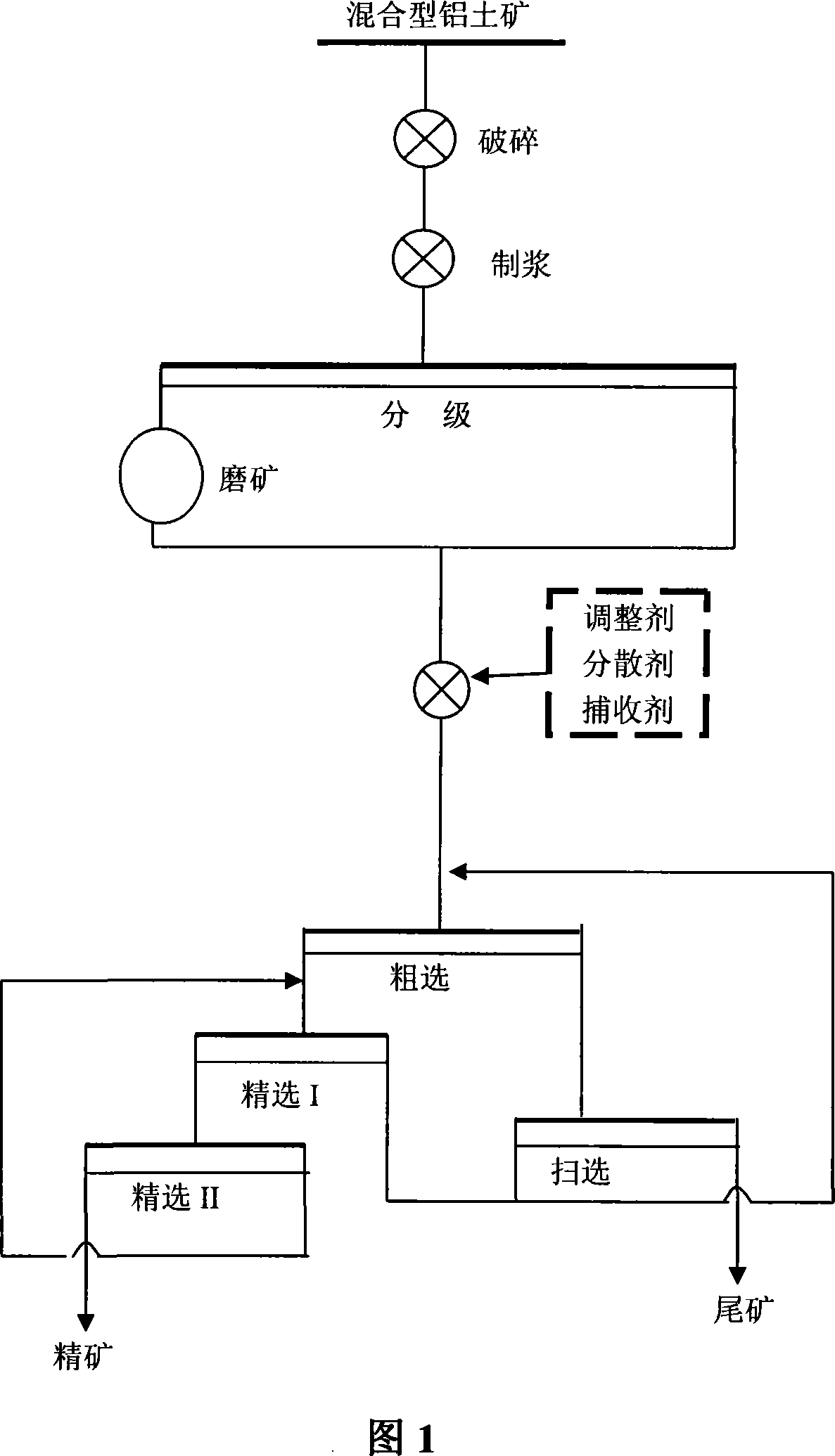

Method used

Image

Examples

Embodiment 1

[0022] 1. Taking the low-grade gibbsite-type bauxite ore in Fiji as the sample, the main phase composition of the ore is gibbsite and kaolin. The chemical composition analysis of the raw ore is shown in Table 1, and the phase analysis is shown in Table 2.

[0023] The ore is selectively crushed by a jaw crusher to a particle size of -20mm, and water is added to adjust the slurry. The concentration of the slurry is 20% to 30%. The slurry is scrubbed by a cylinder washing machine for 5 to 10 minutes. The high-quality kaolin is separated from the gibbsite particles under the action of hydraulic force and stirring, and the coarse particles of +1mm are sieved by spiral vibration, and the A / S of the coarse particles is greater than 8, which can be directly used as concentrates; For gibbsite and kaolin, use spiral classifier to classify, +0.1~+0.074mm particles are selectively ground by ball mill, overflow particle size is -0.074mm, content is 85~90%, and sieved -0.1 ~0.074mm ore pu...

Embodiment 2

[0031] Taking a medium-low grade gibbsite and boehmite mixed bauxite in Saudi Arabia as a sample, the phase composition of the ore is mainly gibbsite, boehmite, kaolin and a small amount of quartz. The chemical property analysis of the raw ore is shown in Table 4, and the phase analysis is shown in Table 5.

[0032] The ore is selectively broken down to a particle size of -20mm by a jaw crusher, and water is added to adjust the slurry. The concentration of the slurry is 30-60%. The slurry is mechanically stirred in the mixing tank for 15-20min, and the gibbsite and boehmite particles It will selectively disintegrate with kaolin, vibrating screening is used for the pulp, and the coarse particles of +0.1mm enter the pair of rollers for further grinding, so that the ore is further dissociated. Grinding products are vibrating and sieving, and the +0.074mm is mainly quartz sand, and the A / S is lower than 1.5, which is directly discarded as tailings; the -0.1mm ore pulp and -0.074mm...

Embodiment 3

[0040]A medium-low grade diaspore and boehmite mixed bauxite in Chongqing, China was used as the sample. The phase composition of the ore is mainly diaspore, boehmite, kaolin and illite. The chemical property analysis of the raw ore is shown in Table 7, and the phase analysis is shown in Table 8.

[0041] The ore is selectively crushed by a jaw crusher to a particle size of -20mm, and water is added to adjust the slurry. The concentration of the slurry is 30-60%. The slurry is mechanically stirred in a mixing tank with a small amount of steel balls for 5-10 minutes. Boehmite , Kaolin and illite are soft and selectively disintegrated with diaspore, and the pulp is classified by spiral, and the coarse particles of +0.2mm are classified into the ball mill for further grinding, so that the ore is further dissociated, and the overflow and - The 0.2mm pulp is mixed into the secondary grinding stage, and the content of -0.074mm in the overflow is 85-90%, and it enters the stirring t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com