Electrolytic manganese residue innocent treatment method and device thereof

A technology of harmless treatment and electrolysis of manganese slag, applied in the direction of solid waste removal, etc., can solve the problems of high investment and operation costs, environmental pollution of electrolytic manganese slag, etc., to reduce equipment investment costs and operating costs, save energy and reduce consumption The effect, the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

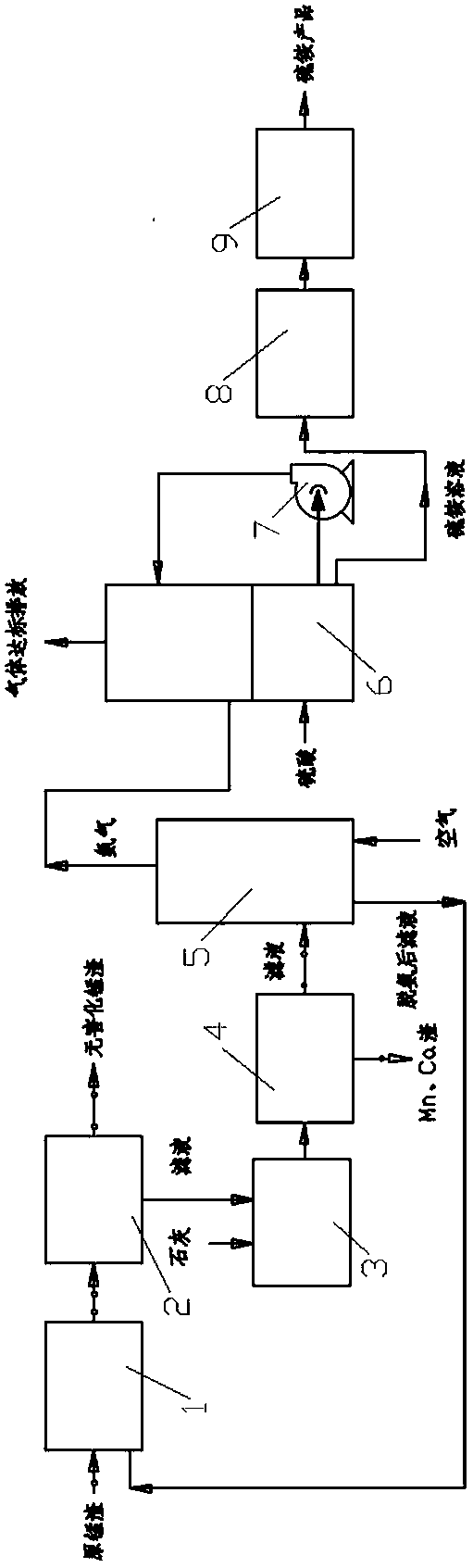

[0044] As shown in the figure, the device in this implementation includes a slag washing tank, a primary filter press, a reaction tank, a secondary filter press, a stripping device, an ammonia absorption tower, a circulation pump, an evaporation concentrator, and a crystallization dryer. Among them, the slag washing pool, the first-stage filter press, the reaction pool, the second-stage filter press, and the blow-off device are connected in sequence through pipelines. The exhaust port at the upper end of the stripping device is connected to the gas inlet at the lower end of the ammonia absorption tower through a pipeline, and the stripping device is connected to the slag washing pool through a pipeline, and the filtrate after deammonization in the stripping device can be returned to the slag washing pool for reuse. At the same time, the ammonia absorption tower, evaporative concentrator, and crystallization drier are connected through pipelines, so that the ammonium sulfate sol...

Embodiment 2

[0050] The device used in this embodiment is the same as in Embodiment 1.

[0051] The manganese slag treatment capacity of this embodiment is 150t / h, and the liquid-solid ratio of 3:1 is used for water washing; while washing, stirring is carried out, and the reaction time is 2 hours; after the water washing is completed, the first mixture is obtained. Before water washing, the ammonia nitrogen content in the slag was 0.62wt% (equivalent ammonia content was 0.75wt%), and the soluble manganese content was 1.17wt%. After washing with water, the ammonia nitrogen content in the harmless manganese slag is 0.03wt%, and the soluble manganese content is 0.07wt%. Before washing, the ammonia content in the circulating water was 1021 mg / L, and after washing, the ammonia content was 2262 mg / L.

[0052] The obtained first mixture (ie washed slag and water) is separated through a primary filter press (ie plate and frame filter press) to obtain harmless manganese slag and primary filtrate. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com