Cutting and cementing method for annular metal material

A metal material, ring-shaped technology, applied in household components, household appliances, other household appliances, etc., can solve the problems of complex process, abnormally many product assemblies, low utilization rate of product materials, etc., to achieve streamlined process, obvious market competition advantages, The effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

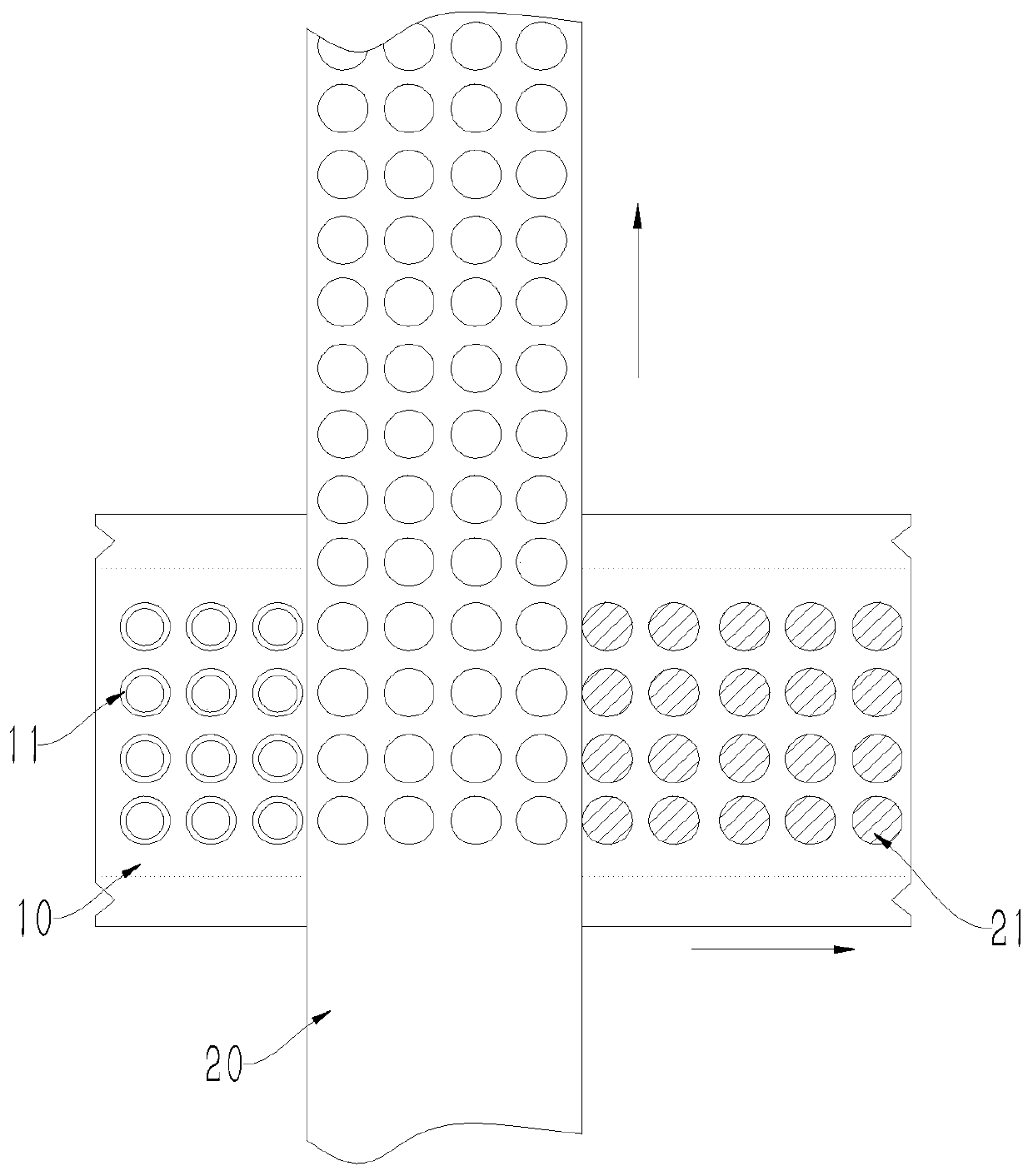

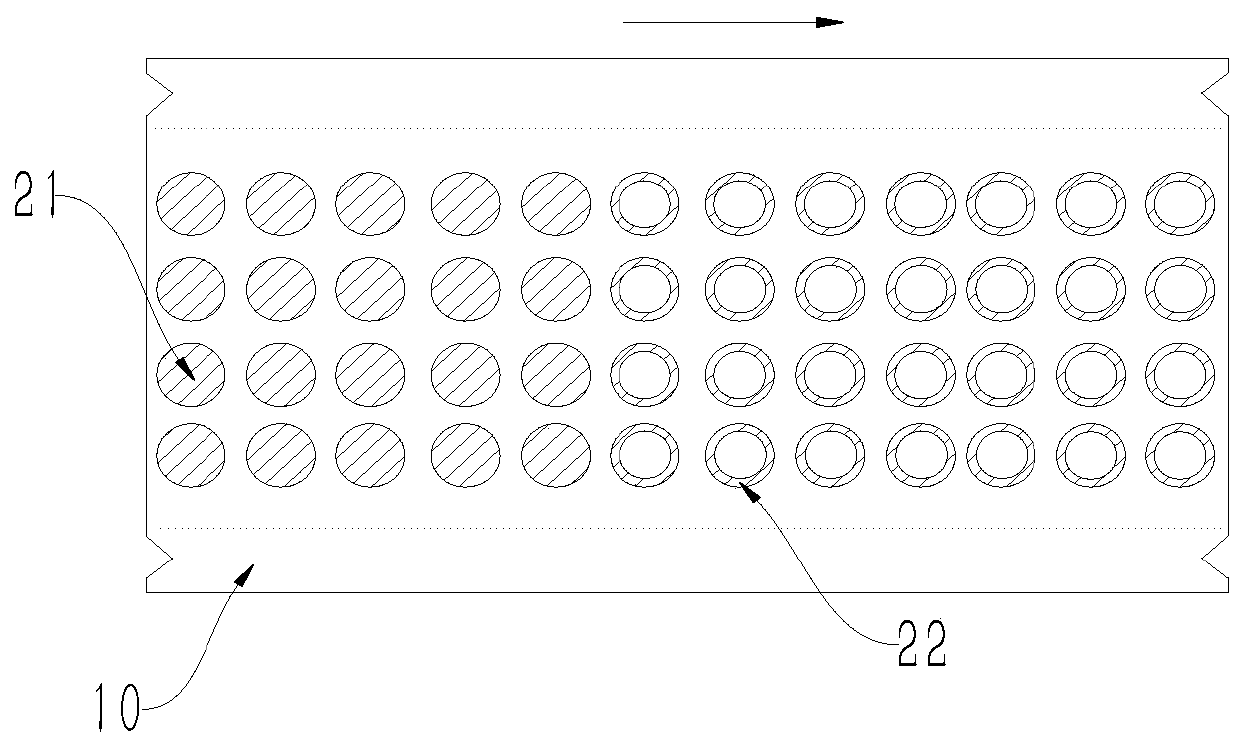

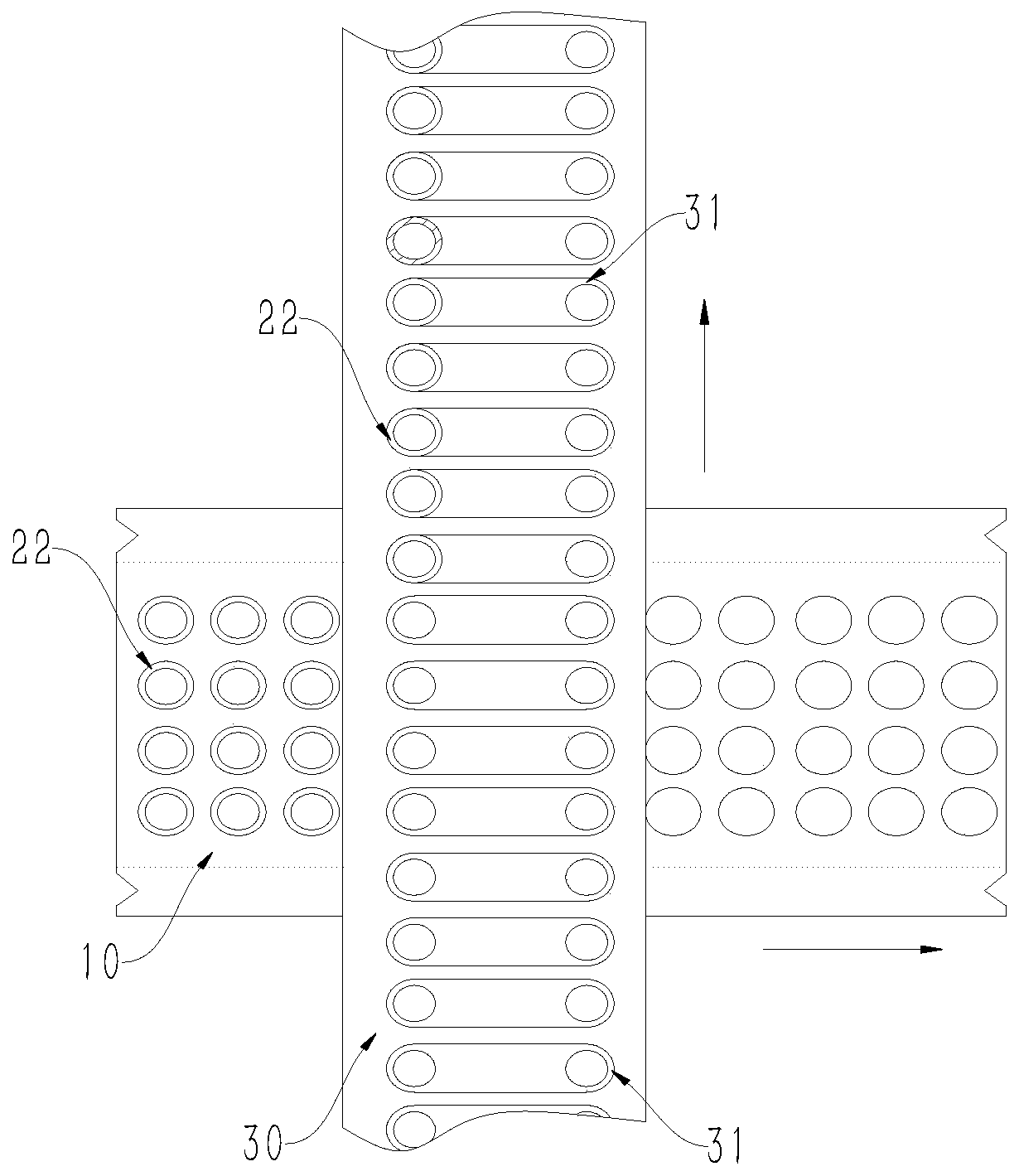

[0023] Figure 1 ~ Figure 3 A method for cutting and gluing ring-shaped metal materials according to an embodiment of the present invention is schematically shown, specifically, including the following steps:

[0024] S1, 10 edges of carrier tape figure 1 Intermittent feeding in the direction of the middle horizontal arrow; the starting end of the carrier belt 10 is provided with a glue-applying device. The annular glue 11 is evenly arranged on the carrier tape 10; after the arrangement of the annular glue 11 is completed, the carrier tape 10 continues to feed, and when it reaches the next pause point, it is attached to the next area on the carrier tape 10 by the glue applying equipment. Put on a plurality of ring glue 11, repeat like this, attach ring glue 11 on the carrier tape 10 intermittently.

[0025] S2, choose a metal sheet 20 with a thickness of 0.03mm, the metal sheet 20 is a steel sheet, and the steel sheet is on the upper edge of the carrier tape 10 figure 1 The...

Embodiment 2

[0030] This embodiment adopts the same method as that of embodiment 1 to process the ring-shaped metal piece. The difference from embodiment 1 is that the metal sheet 20 is a copper sheet, and the thickness of the copper sheet is 0.15 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com