Nested radiator

A radiator and heat sink technology, which is applied to lighting and heating equipment, cooling/heating devices for lighting devices, lighting devices, etc., can solve the problems of inability to make thin sheet heat dissipation surfaces, and the shape cannot be changed, so as to save costs and reduce consumption. , the effect of increasing the heat dissipation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

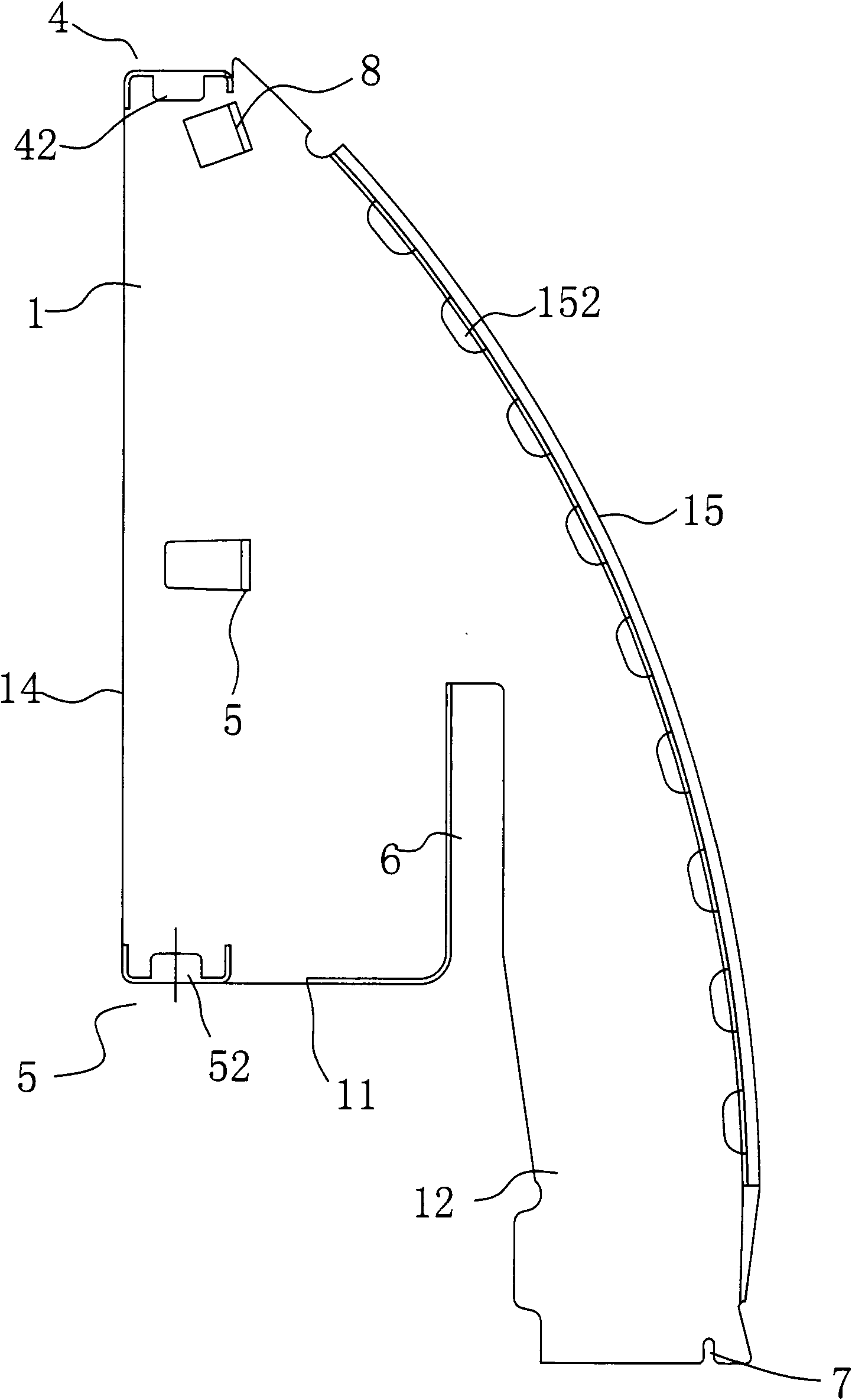

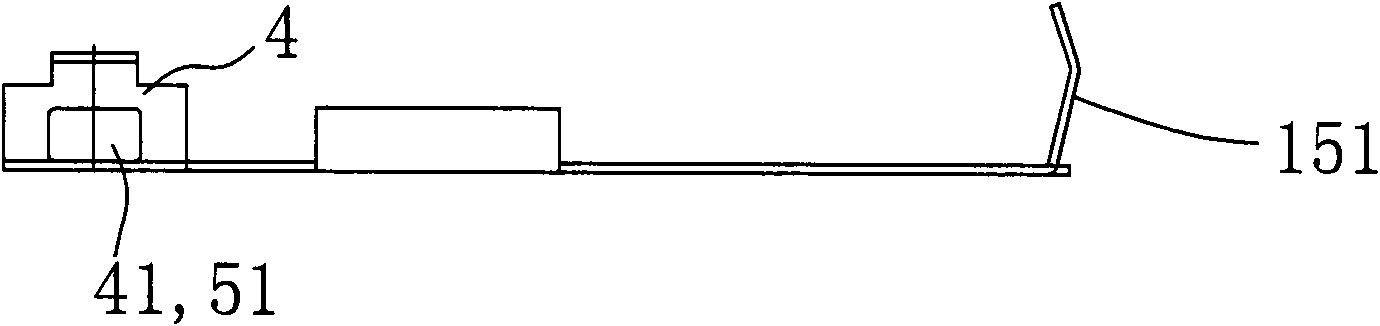

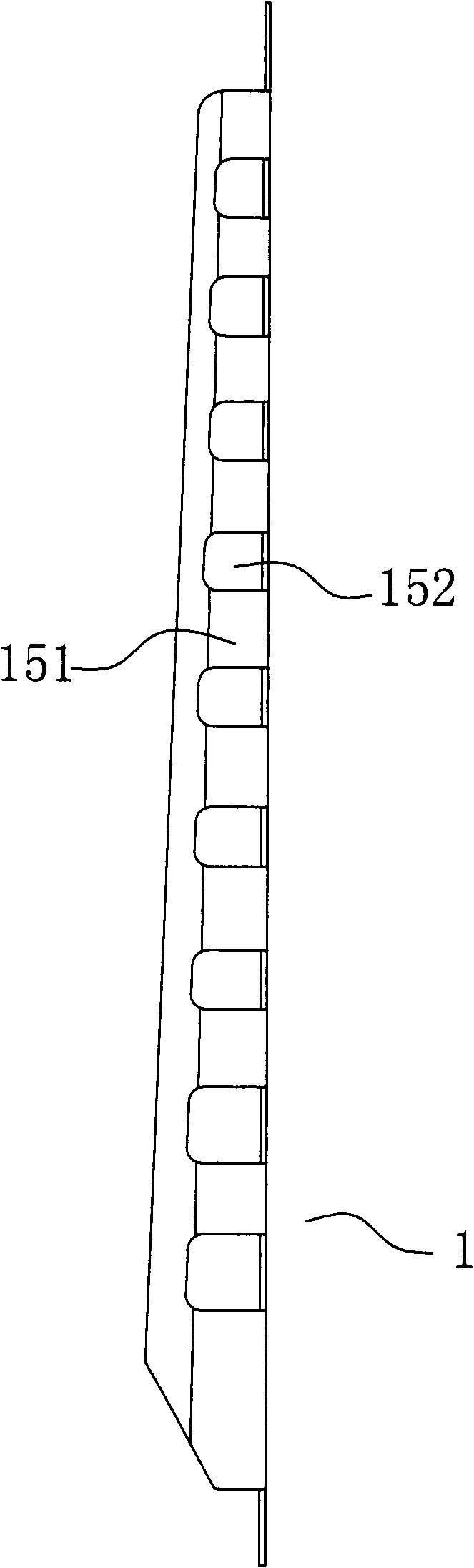

[0020] See Figure 1-3 As shown, the heat sink 1 in the present invention is a thin sheet of aluminum alloy material, on which are provided structures such as buckles, stoppers, connecting pieces, holes, etc., and these structures are formed by punching the heat sink 1, and the direction of punching They are all the same, that is, one side of the heat sink 1 is a plane, and the other side is formed by stamping with the above-mentioned buckle, limiting piece, connecting piece, hole and other structures.

[0021] Specifically, the left and right sides of the heat sink 1 are straight sides 14 and arc sides 15 respectively. Among them, the upper and lower ends of one side of the straight side 14 are respectively formed with an upper buckle 4 and a lower buckle 5, and the arc edge 15 extends downward to form an extension 12, which is close to the straight side where the lower buckle 5 is located. 14, and a gap groove 6 is formed between the straight lower end 11 and the extended e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com