Sauced split duck leisure food and production method thereof

A technology of snack food and production method, which is applied in the field of food processing, can solve the problems of not meeting the needs of consumers, high moisture content of products, long production cycle of sauced duck, etc., achieve good chewiness, improve product quality, and improve product elasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

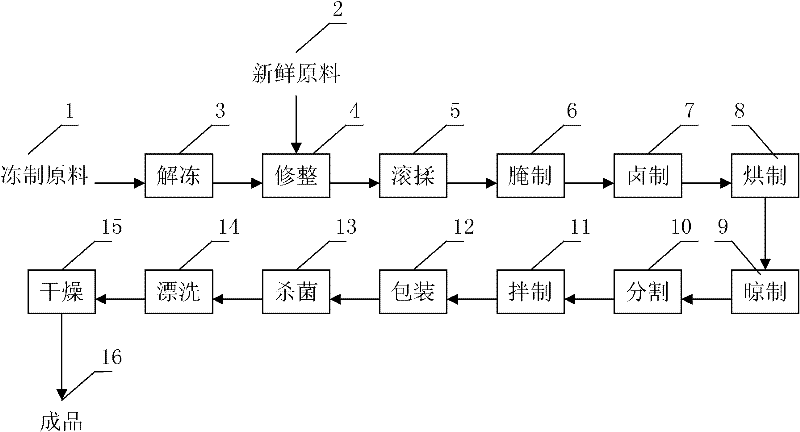

Method used

Image

Examples

Embodiment 1

[0052]Frozen duck necks are used as raw materials, and the raw materials are thawed in a thawing room at a temperature of 15°C for 10 hours until the center temperature of the raw materials is -2°C; the stubble, fat, diseased tissues, bruises and dirt on the duck necks are thoroughly removed Wait until the duck necks that do not meet the requirements are selected; the trimmed duck necks are first rinsed in a clear water pool, and then cleaned one by one to fully remove the blood and impurities and dirt on the surface of the duck necks; put the trimmed duck necks into the tumbler Add marinating accessories: 100 parts of trimmed duck neck, 1.0 part of salt, 0.2 part of soy sauce, 0.2 part of chicken essence, 0.2 part of monosodium glutamate, 0.002 part of I+G, 0.03 part of white sugar, 0.02 part of rock sugar, 0.1 part of cooking wine 0.1 part of white wine, 0.02 part of caramel pigment, 0.007 part of red yeast rice, 0.007 part of sauce stewed yellow, 0.05 part of sodium erythorb...

Embodiment 2

[0054] Frozen duck wings are used as raw materials, and the raw materials are thawed in a thawing room at a temperature of 16°C for 11 hours until the center temperature of the raw materials is -1°C; the stubble, diseased tissue, congestion and dirt on the duck wings are thoroughly removed, Pick out the duck wings that do not meet the requirements; rinse the trimmed duck wings in a clear water pool first, and then wash them one by one to fully remove the blood and impurities and dirt on the surface of the duck wings; put the trimmed duck wings into the tumbler, Then add marinating accessories: 100 parts of trimmed duck wings, 1.1 parts of salt, 0.005 parts of I+G, 0.10 parts of white sugar, 0.2 parts of cooking wine, 0.02 parts of caramel pigment, 0.05 parts of sodium erythorbate, and 0.05 parts of pepper ;Turn and knead for 35 minutes under the conditions of vacuum degree 0.09MPa and rotation speed of 15r / min, and the temperature in the tumbling room is 0-4°C; transfer the tum...

Embodiment 3

[0056] Use fresh duck feet as raw materials, thoroughly remove the aging skin, nails, diseased tissues, congestion and dirt on the duck feet, and select the duck feet that do not meet the requirements; rinse the trimmed duck feet in a clear water pool, and then wash them one by one , fully remove blood and impurities and dirt on the surface of duck feet; put the trimmed duck feet into the tumbler, and then add pickling accessories: 100 parts of trimmed duck feet, 0.8 parts of salt, 0.5 parts of chicken essence, rock sugar 0.08 parts, 0.2 parts of white wine, 0.008 parts of Monascus Red, 0.005 parts of sodium nitrite, 0.07 parts of meat aroma source; tumble for 40min under the condition of vacuum degree of 0.08MPa and speed of 20r / min, the temperature between tumble and kneading is 0~ 4°C; transfer the tumbled duck feet into the stainless steel pickling tank in the pickling room, cover with plastic wrap and marinate for 48 hours, the temperature in the pickling room is 0-4°C; tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com