Preparation method of modified polysiloxane microspheres with controllable particle sizes

A technology of polysiloxane and siloxane monomer, which is applied in the field of preparation of modified polysiloxane microspheres, which can solve the problems of limited application range and achieve the effect of narrow particle size distribution and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

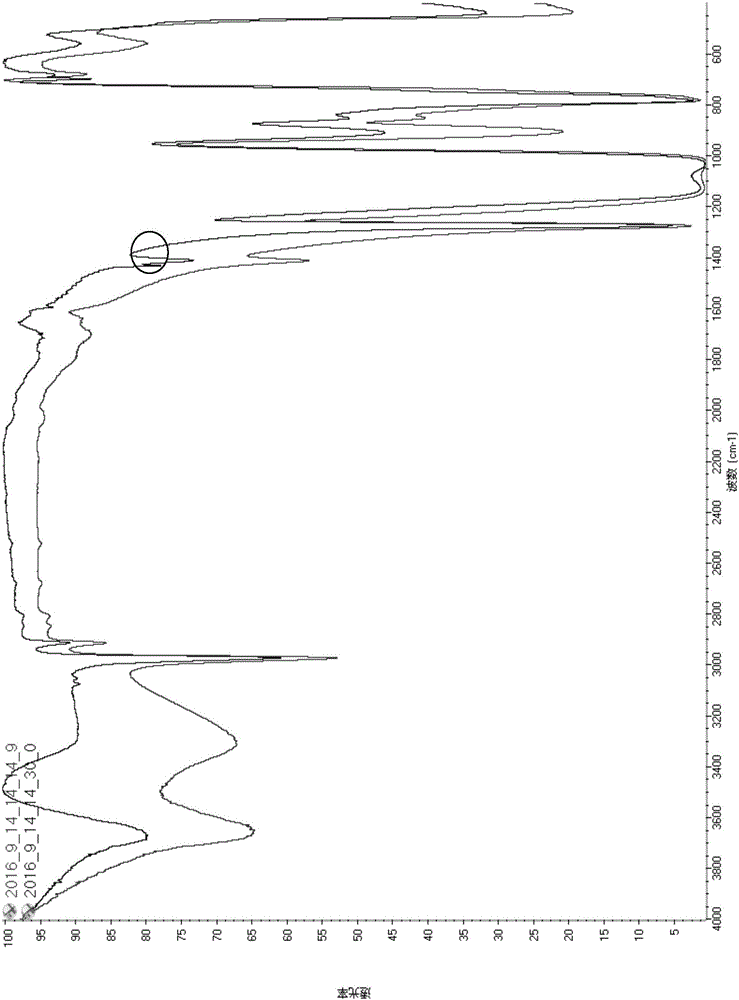

Image

Examples

preparation example Construction

[0048] The invention provides a preparation method of modified polysiloxane microspheres, comprising the following steps:

[0049] A) mixing siloxane monomers, acid catalysts and water, and hydrolyzing to obtain a silanol solution;

[0050] The electrical conductivity of the water is 5-60 μs / cm;

[0051] B) Putting a basic catalyst into the silanol solution obtained in the above steps to carry out a condensation reaction, then raising the temperature and adding a modifying agent, and reacting again to obtain modified polysiloxane microspheres.

[0052]In the invention, the siloxane monomer, the acidic catalyst and water are firstly mixed, and after hydrolysis, a silanol solution is obtained.

[0053] The electrical conductivity of the water in the present invention is preferably 5-60 μs / cm, more preferably 15-50 μs / cm, more preferably 25-40 μs / cm, most preferably 30-35 μs / cm.

[0054] The present invention has no special restrictions on the siloxane monomers, and the siloxan...

Embodiment 1

[0075] 2μm microspheres

[0076]In a 2L four-neck flask equipped with a stirring, thermometer and reflux condenser, add 1404g of water with a conductivity of 5μs / cm, add 0.8g of hydrochloric acid, raise the temperature to 50°C, and add methyl trimethoxyl dropwise at a stirring speed of 200rpm Base silane 163g, equilibrate reaction for 0.5 hours, then add ammonia water 30g, 20rmp reaction 8h. The reaction solution was heated to 90°C, 15g of double-capped heads were added, reacted for 9h, centrifuged and washed with water until neutral, and dried in a drying oven at 150°C to obtain hydrophobically modified polysiloxane microspheres.

[0077] The hydrophobically modified polysiloxane microspheres prepared in Example 1 of the present invention were characterized and counted, and the yield was 92.8%.

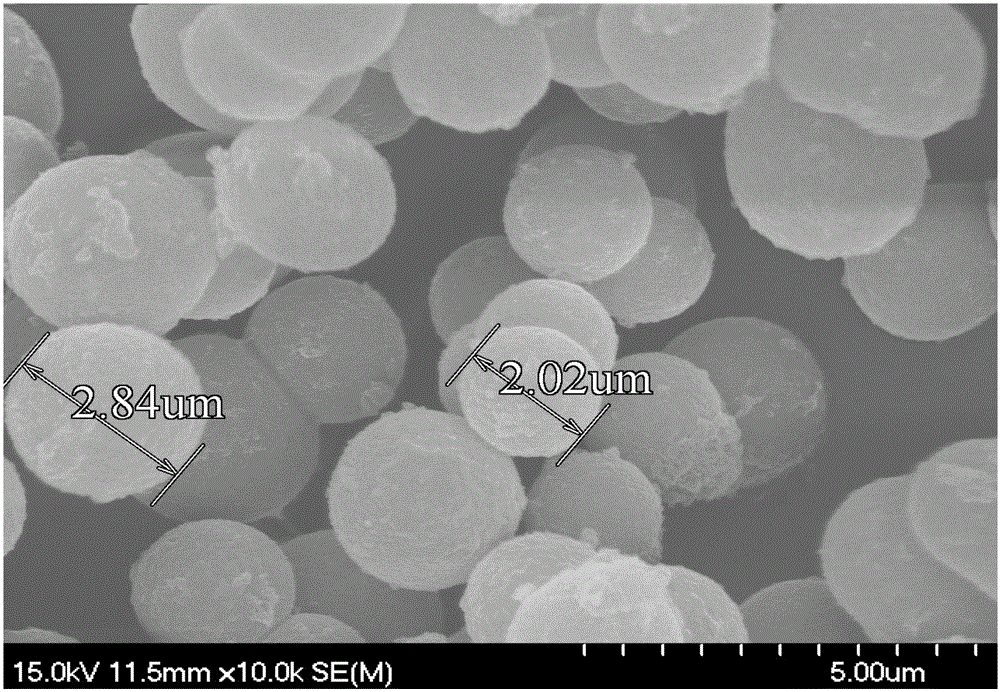

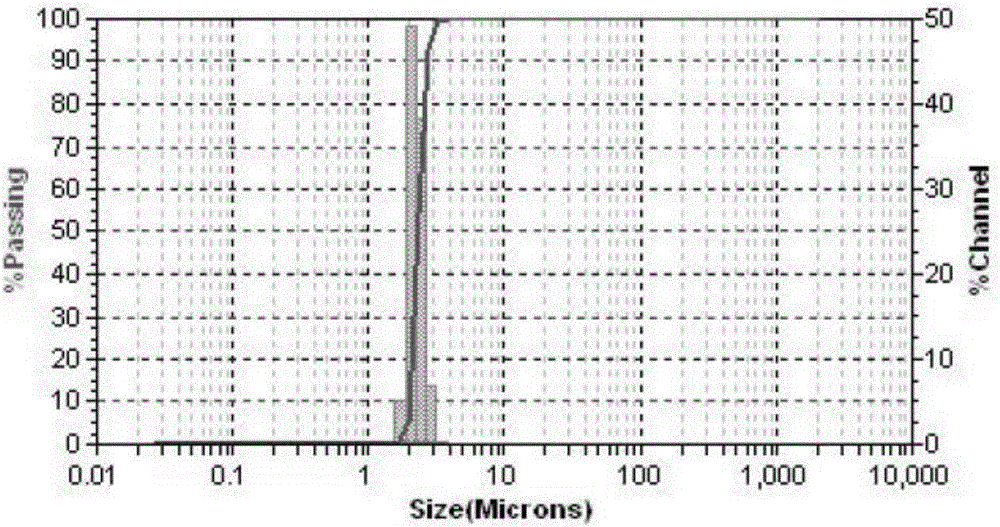

[0078] see figure 1 , figure 1 Scanning electron micrograph of the hydrophobically modified polysiloxane microspheres prepared in Example 1 of the present invention. Depend on f...

Embodiment 2

[0086] 3μm microspheres

[0087] In a 2L four-neck flask equipped with a stirring, thermometer and reflux condenser, add 1404g of water with a conductivity of 7μs / cm, add 0.9g of acetic acid, raise the temperature to 30°C, and add methyl trimethoxyl at a stirring speed of 300rpm Silane 176.8g, equilibrated for 1 hour, then added KOH 20g and stirred evenly, 25rmp for 10 hours. Heat the reaction solution to 80°C, add 5g of KH570, react for 7h, centrifuge and wash with water until neutral, and dry in a drying oven at 150°C to obtain acrylic modified silicone resin microspheres.

[0088] The acrylic-modified silicone resin microspheres prepared in Example 2 of the present invention were characterized and counted, and the yield was 94.5%.

[0089] see image 3 , image 3 Scanning electron microscope image of the acrylic modified silicone resin microspheres prepared in Example 2 of the present invention. Depend on image 3 It can be seen that the particle size of the acrylic mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com