Ultra-thin metal grid-based transparent electrode and preparation method thereof

A transparent electrode, ultra-thin metal technology, applied in cable/conductor manufacturing, conductive layer on insulating carrier, nanotechnology for materials and surface science, etc., can solve the problem of reducing the surface energy difference of metal and substrate, metal surface Poor wettability, weak light transmittance, etc., to achieve the effect of low vacuum, low cost, and less material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

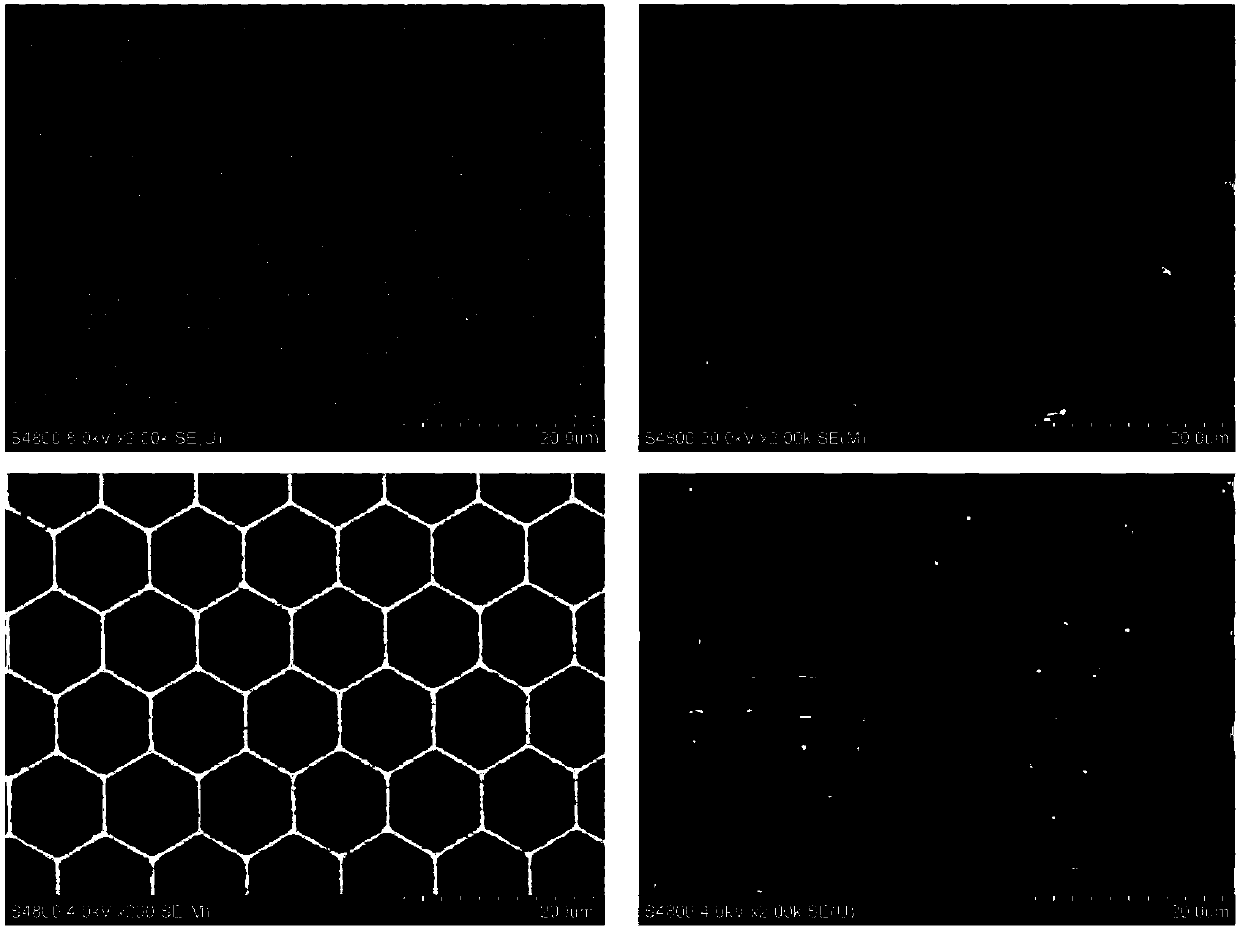

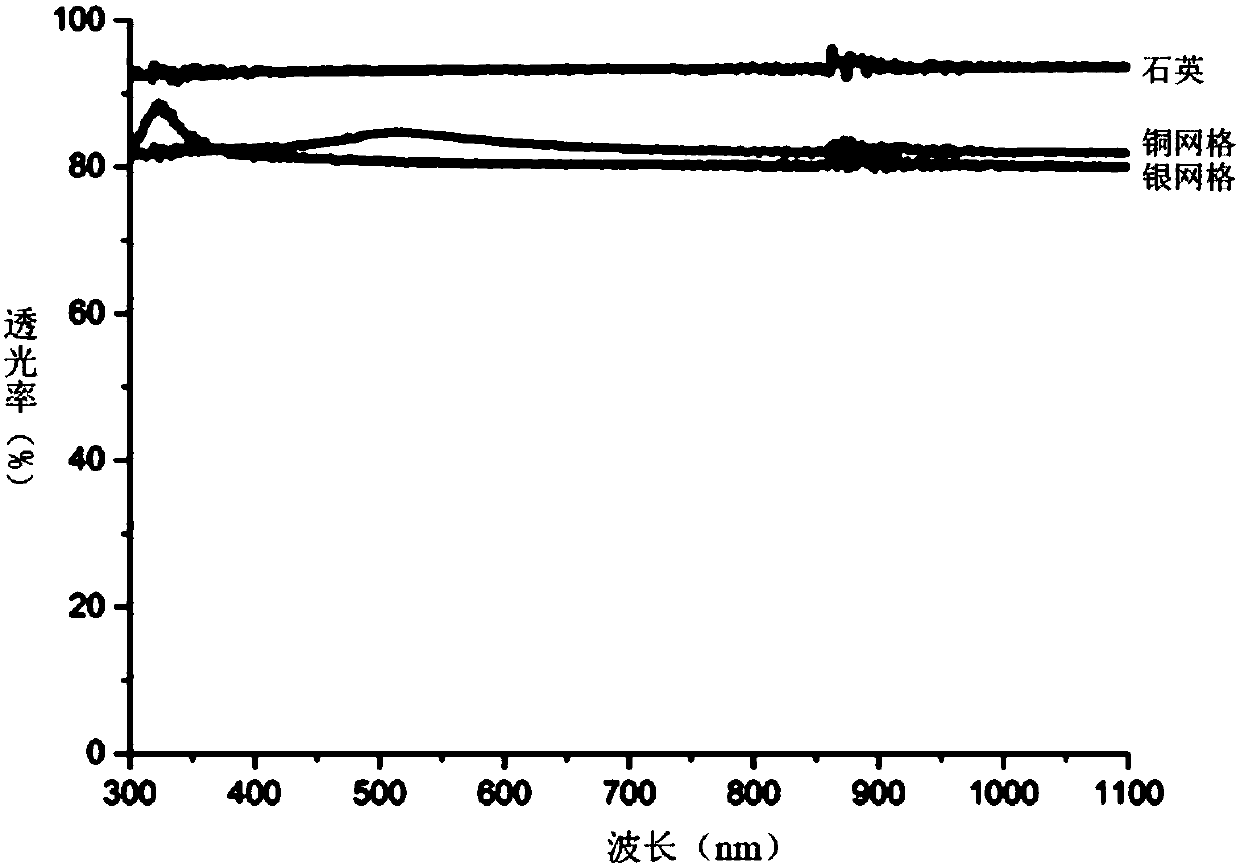

[0037] A transparent electrode based on an ultra-thin metal grid, the transparent electrode generally includes a flexible transparent substrate, and an Ag grid layer with a thickness of 9 nm is deposited on one side of the flexible transparent substrate.

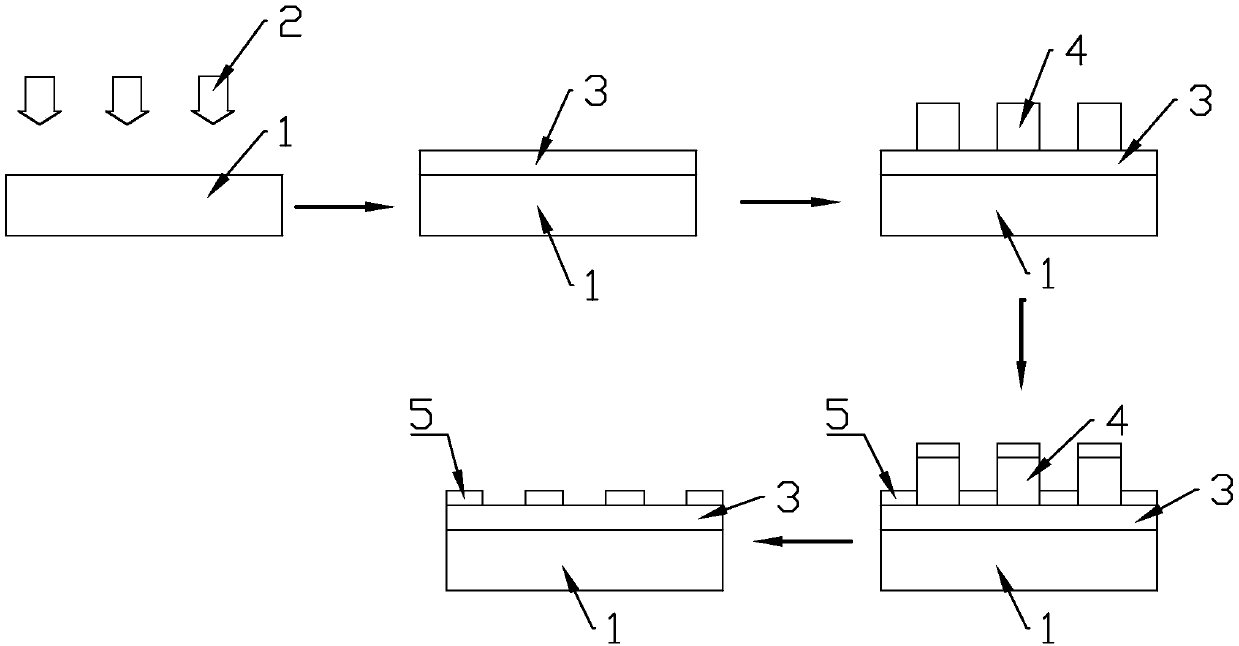

[0038] The ultra-thin metal grid transparent electrode is prepared by the following method:

[0039] (1) UV treatment is carried out to the flexible transparent substrate;

[0040] (2) Use polyetherimide (PEI) to graft a layer of amine groups on the surface of the flexible transparent substrate;

[0041] (3) Forming a mask with a period of 1400 nm on the surface of the substrate by colloid printing;

[0042] (4) Using the method of electron beam evaporation, metal Ag is deposited on the mask plate, and the initial pressure is 6×10 4 Pa, the evaporation rate is 1.7 angstroms / s, the power is 9kw, the coating stops after 9s, and a 9nm silver grid film is grown on the substrate surface at the gap of the mask;

[0043] (5) Tak...

Embodiment 2

[0052] A transparent electrode based on an ultra-thin metal grid, the transparent electrode generally includes a flexible transparent substrate, and an Au grid layer with a thickness of 9 nm is deposited on one side of the flexible transparent substrate.

[0053] The transparent electrode of the ultra-thin metal grid is prepared by the following method:

[0054] (1) UV treatment is carried out to the flexible transparent substrate;

[0055] (2) Use polyetherimide (PEI) to graft a layer of amine groups on the surface of the flexible transparent substrate;

[0056] (3) Form a mask plate with a period of 100 μm on the surface of the substrate by photolithography technology;

[0057] (4) Using the method of electron beam evaporation, metal Au is deposited on the mask plate, and the initial pressure is 6×10 4 Pa, the power is 9kw, the evaporation rate is 6 angstroms / s, the coating stops after 9s, and a 9nm Au grid film is grown on the substrate surface at the gap of the mask;

[0...

Embodiment 3

[0061] A transparent electrode based on an ultra-thin metal grid. The transparent electrode includes a flexible transparent substrate, and a double-period Ag and Au grid layer is deposited on one side of the flexible transparent substrate.

[0062] The transparent electrode of the ultra-thin metal grid is prepared by the following method:

[0063] (1) UV treatment is carried out to the flexible transparent substrate;

[0064] (2) Use polyetherimide (PEI) to graft a layer of amine groups on the surface of the flexible transparent substrate;

[0065] (3) Forming a mask with a period of 1400 nm on the surface of the substrate by colloid printing;

[0066] (4) Using the method of electron beam evaporation, metal Ag is deposited on the mask plate, and the initial pressure is 6×10 4 Pa, the power is 9kw, the evaporation rate is 1.7 angstroms / s, the coating stops after 9s, and a 6nm Ag grid film is grown on the substrate surface at the gap of the mask;

[0067] (5) Take out the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Square resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com