Screen printing device

A technology of screen printing device and printing seat, which is applied to screen printing machines, printing machines, printing machines, etc. It can solve the problems of operators sticking to paint, poor applicability, and high price, and achieves simple structure and economic benefits , Strengthen the effect of applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

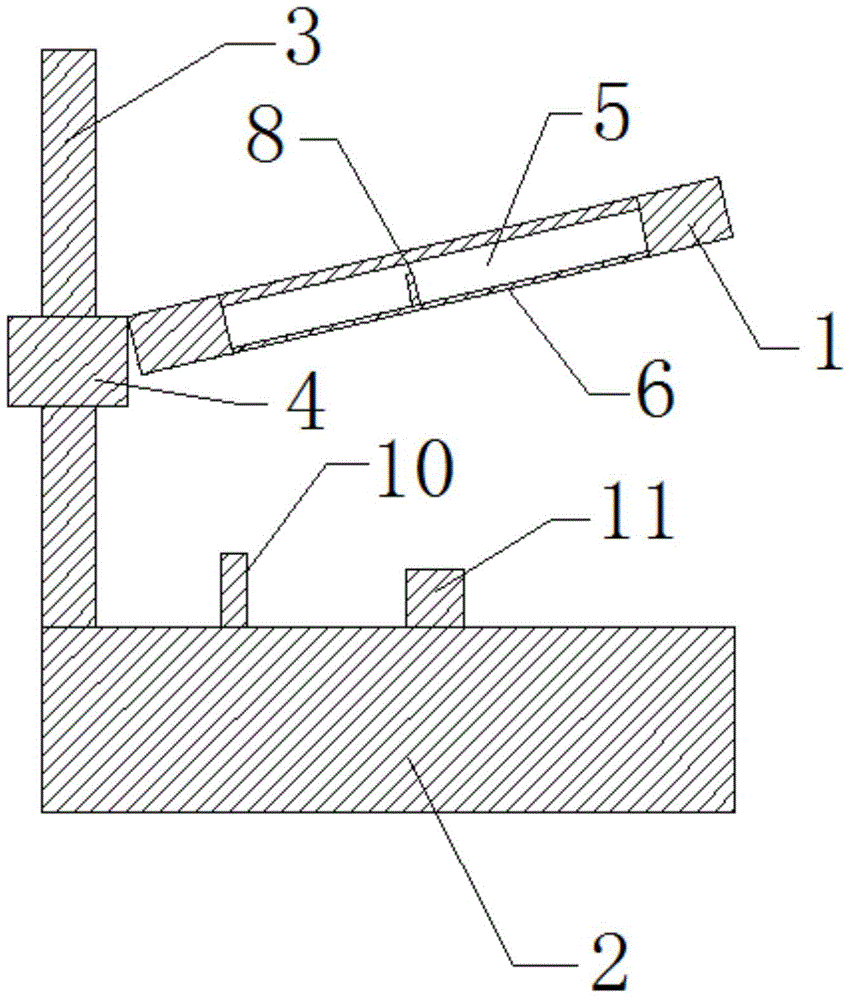

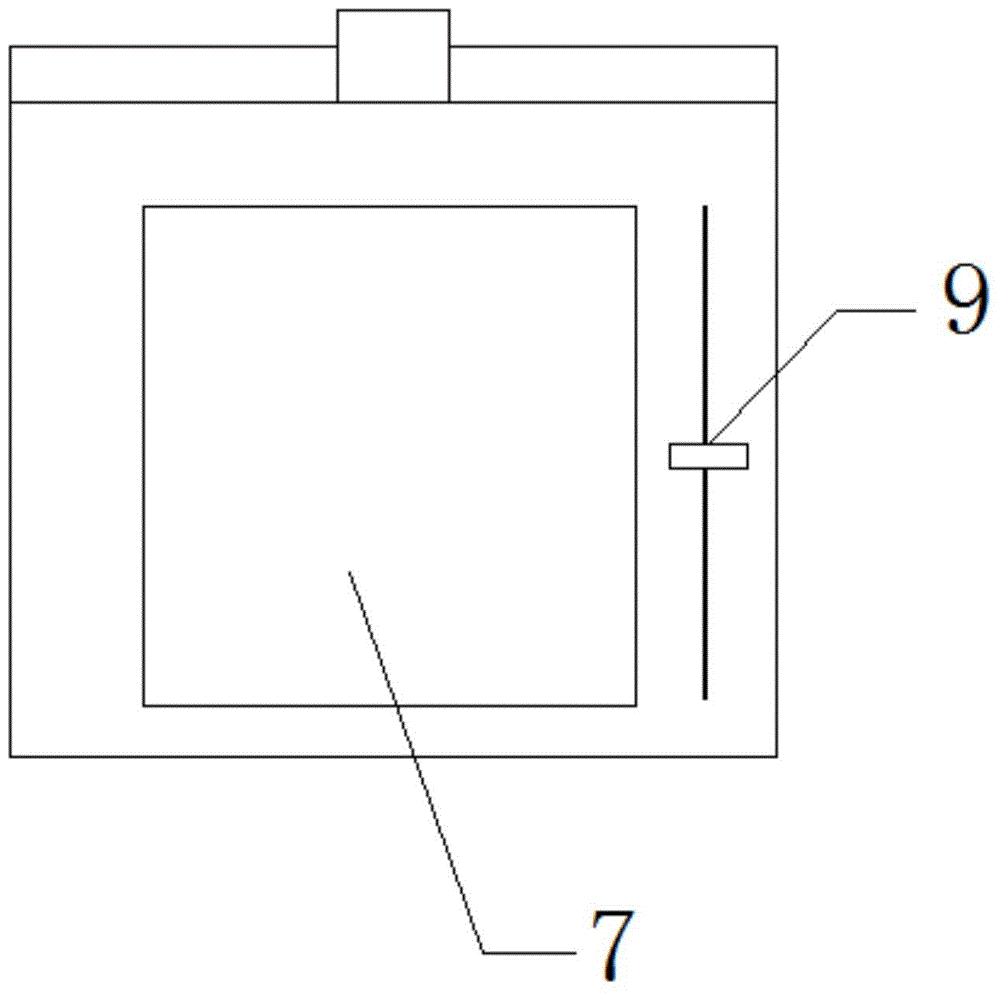

[0018] The present invention provides a kind of screen printing device aiming at existing deficiencies, as figure 1 As shown, it includes a printing seat, a base and a pole arranged on the top of the base; the printing seat is set on the pole with movable blocks; an oil chamber is arranged on the printing seat; the bottom of the oil chamber is provided with Printing screen; the top of the oil chamber is hinged with a chamber cover; the interior of the oil chamber is provided with a scraper attached to the printing screen; the scraper is connected with a paddle arranged on the top of the printing seat.

[0019] The top of the base is also provided with a horizontal positioning block and a vertical positioning block;

[0020] The printing seat and the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com