Vacuum device for reflow soldering furnace

A vacuum device and reflow soldering furnace technology, applied in auxiliary devices, assembling printed circuits with electrical components, welding equipment, etc., can solve problems such as damage, solder joint voids, and inability to discharge gas, reducing size and quantity, and improving reliability. The effect of degree and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

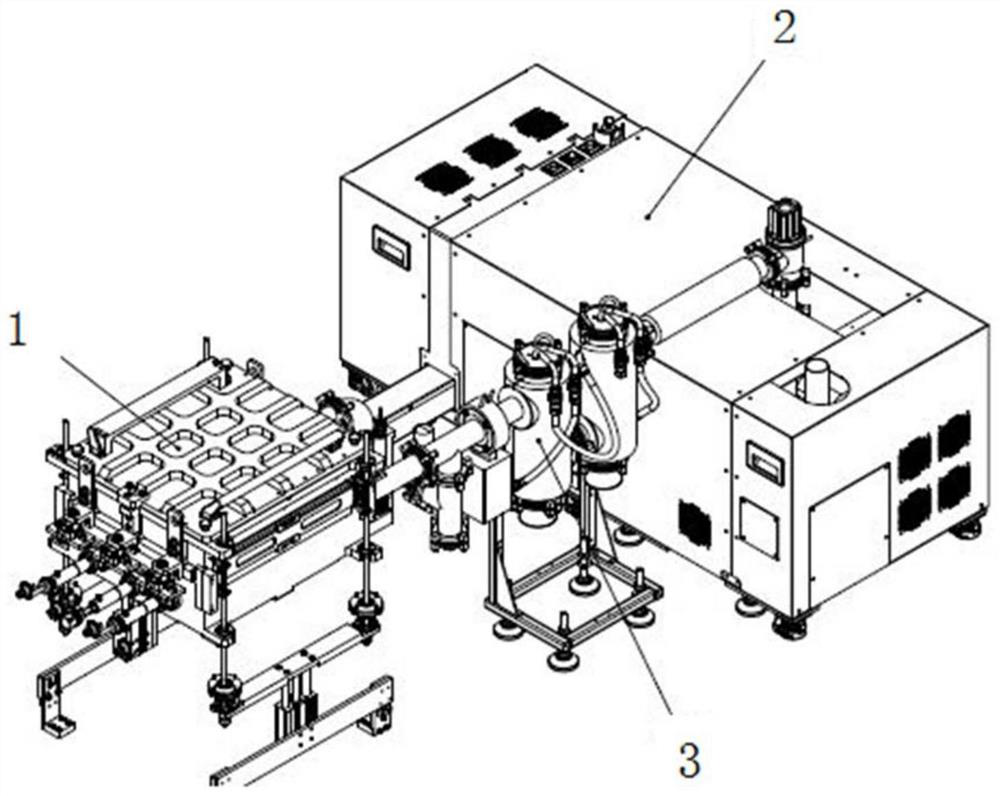

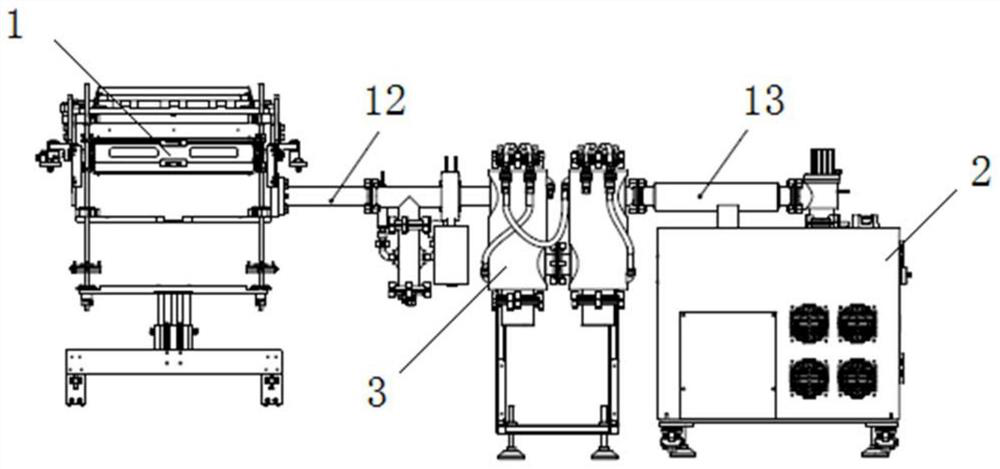

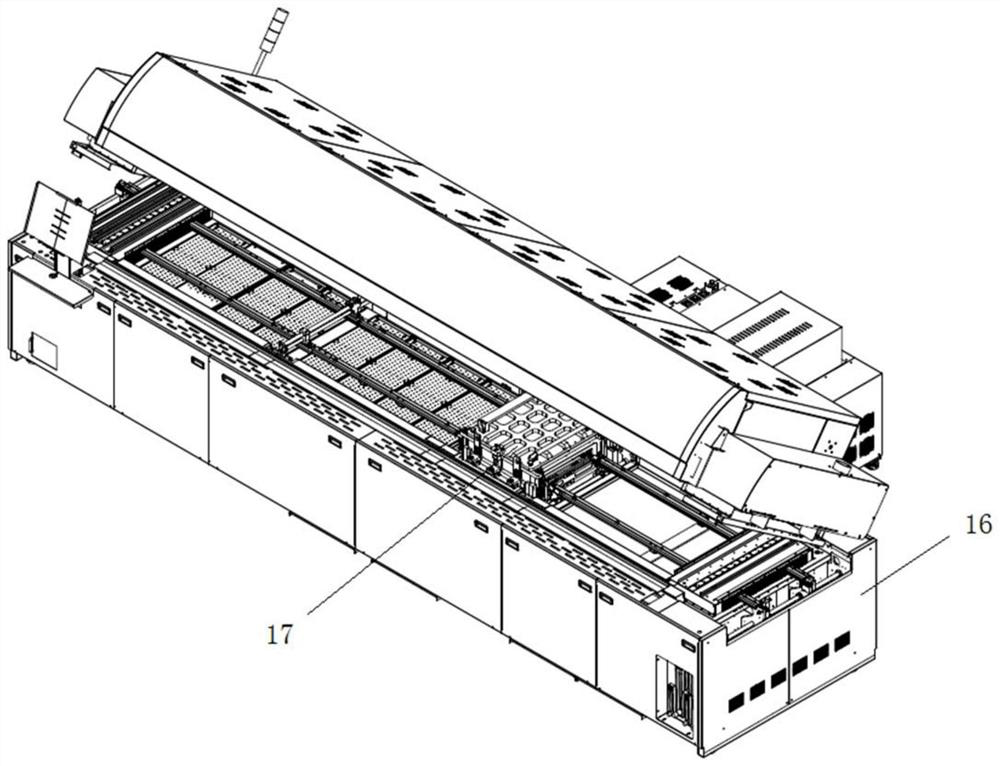

[0030] Such as figure 1 , 2 As shown, the present invention relates to a vacuum device for a reflow oven, which includes a vacuum chamber 1 , a vacuum pump system 2 and a cooling collection auxiliary device 3 . The vacuum cavity 1 is connected to the auxiliary cooling and collection device 3 through a first connecting pipeline 12 , and the auxiliary cooling and collecting device 3 is connected to the vacuum pump system 2 through a second connecting pipeline 13 . The vacuum system 2 is opened and closed through the isolation valve. The vacuum device of the present invention replaces the heating module in the reflow zone in the reflow furnace, that is, the vacuum cavity 1, the vacuum pump system 2 and the cooling collection auxiliary device 3 are installed in the reflow zone of the reflow furnace 16, such as image 3 shown.

[0031] Such as Figure 4 As shown, the vacuum chamber 1 includes a chamber body 4 , a top cover 5 and a side door mechanism 6 . The cavity body 4 is f...

Embodiment 2

[0039] As a more preferred solution, this embodiment is based on the structure of Embodiment 1. The vacuum degree measuring instrument of the cavity body 4 is connected to the PC end, and the controllers of each telescopic cylinder are connected to the PC end, and the vacuum can be completed through the visual operation interface. Operational control and monitoring.

Embodiment 3

[0041] As a more preferred solution, on the basis of the structure of Example 1, an additional heating assembly is provided in the cavity body 4 in this embodiment. Heating module or infrared heating module including filter and other components. Arranging the heating assembly in the cavity body 4 can prolong the process of the melting state of the solder paste, and can increase the effect of vacuuming the vacuum cavity. It should be noted that the infrared heating module of this embodiment can use components that use infrared heating to achieve heating in the prior art, and the specific structure will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com