Hybrid film of polyimide modified by silicon dioxide tube, and preparation method

A technology of silica tube and polyimide, applied in the field of polymer-based nanocomposite materials and its preparation, can solve the problems that the particles cannot meet the use requirements, and achieve the effects of easy popularization and application, low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

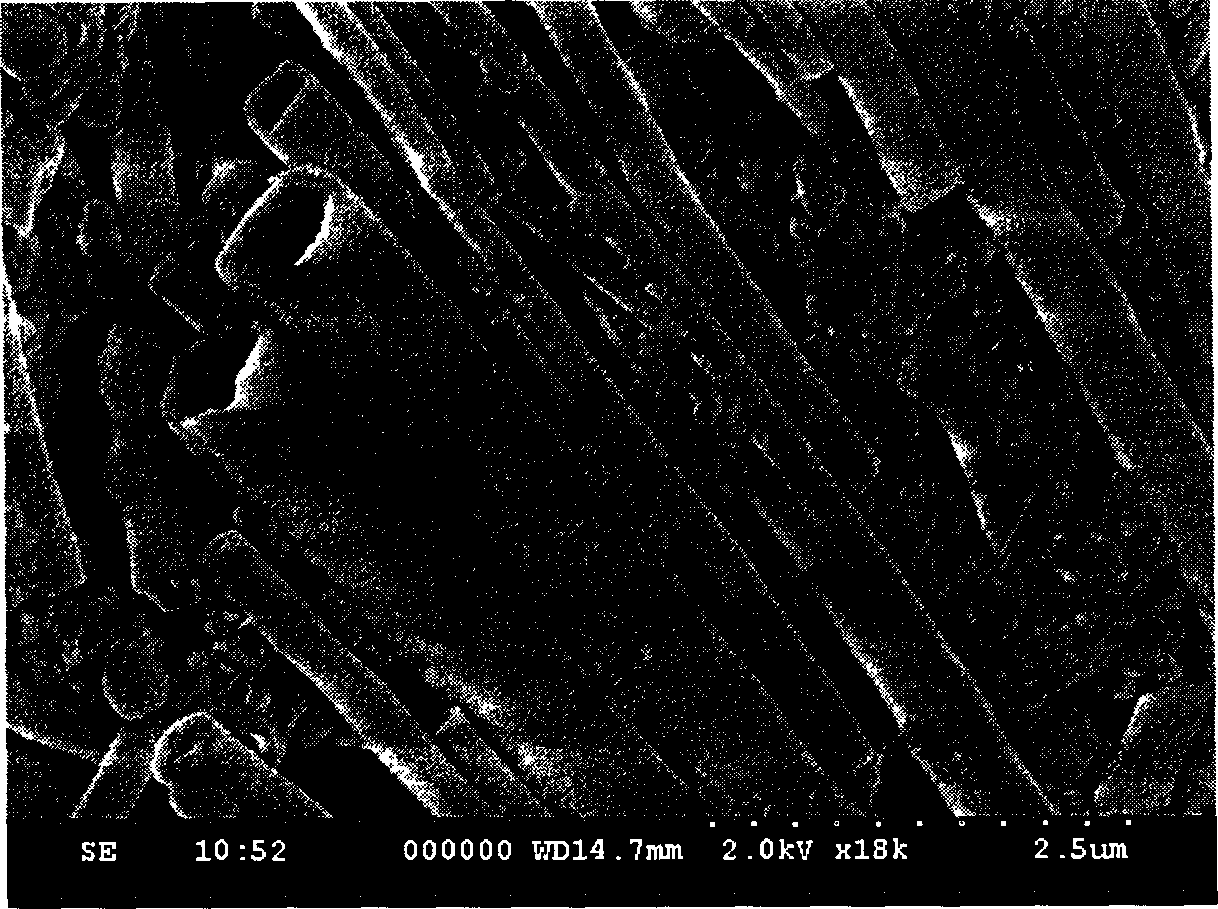

[0048] 1) Dissolve the alkyl sulfonate cationic surfactant in the solution of water and ethanol, the molar concentration by volume is 5mmol / L~25mmol / L, preferably 5mmol / L~8mmol / L, make template aqueous solution and Add 0.1mol / L-3mol / L silicate under stirring, and stand at 15-40°C for 40 minutes to self-assemble; add 1mol / L-5mol / L, preferably 2mol / L, into the mixed solution ~3mol / L of 25~28% (weight percent concentration) concentrated ammonia water was left standstill for 20-70 minutes, and the product obtained was separated with an experimental sieve or a filter membrane, and after washing with a large amount of water, a white powdery material was obtained, which was observed under an electron microscope as super Fine silicon dioxide tubular material with a diameter of 30-350 nanometers and a hollow tube shape. See figure 1 ;

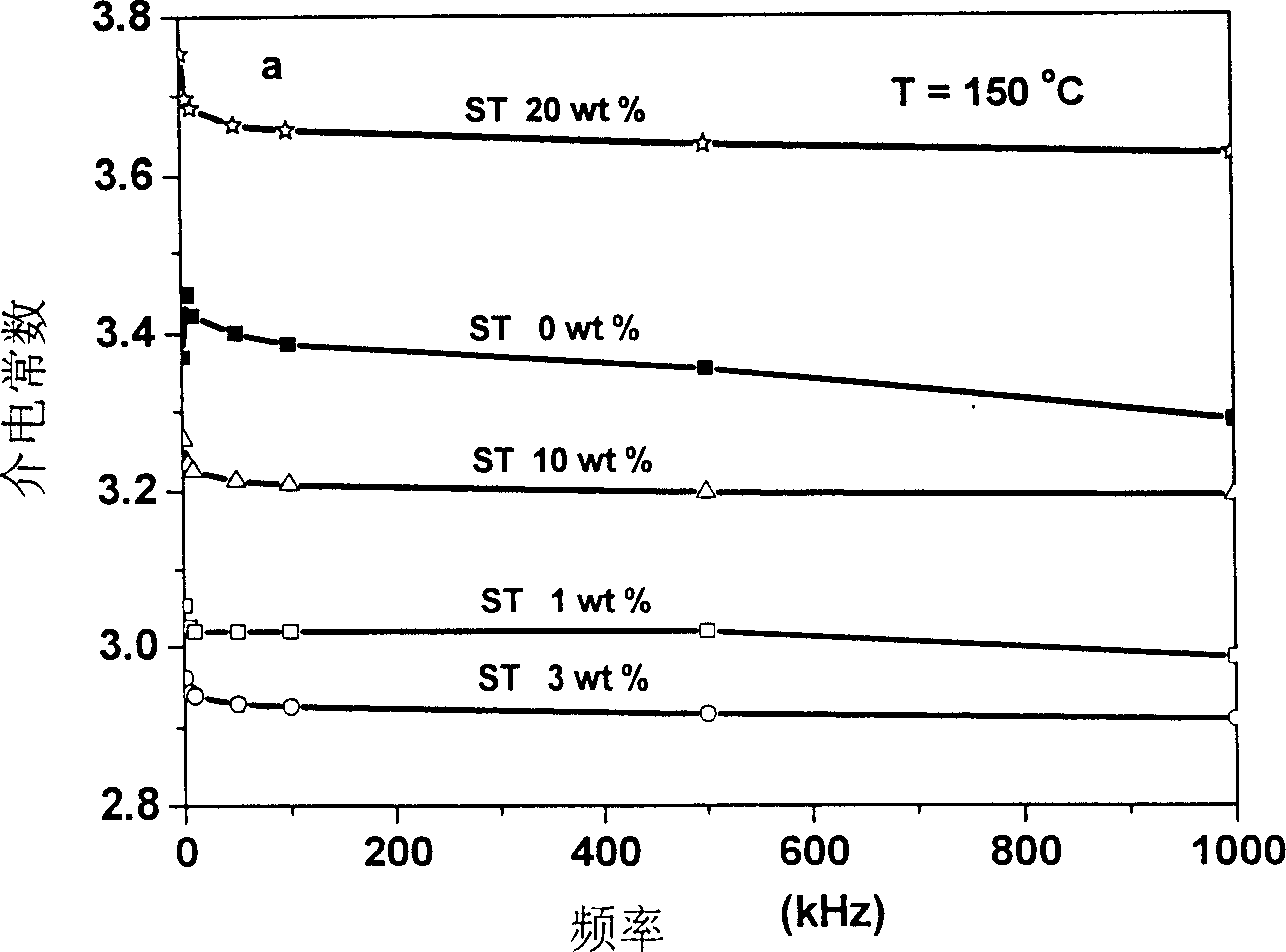

[0049] 2) After the powdery material is naturally dried, it is weighed according to the ratio of 1-3% of the resin content, and then added to a solut...

Embodiment 2

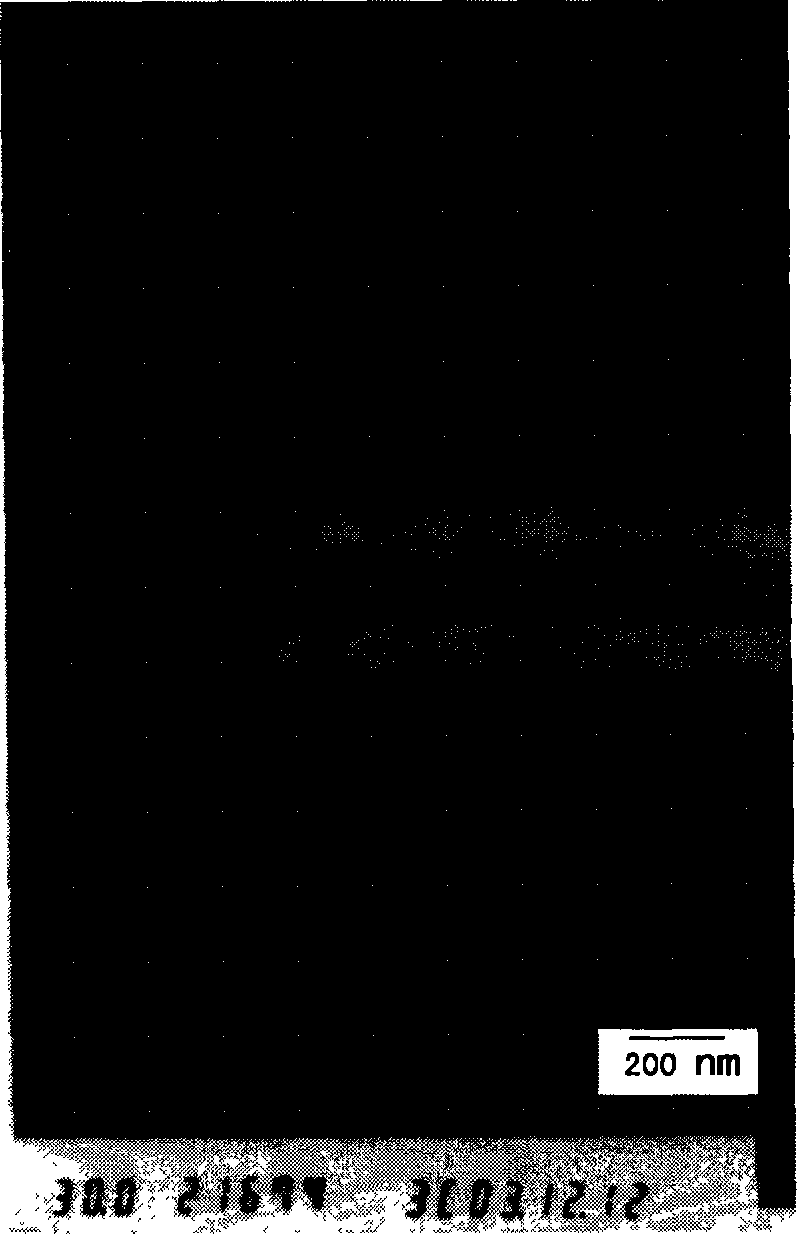

[0053] According to the steps of Example 1, 4 mmol succinic acid was dissolved in the solution of water and ethanol, and the template material solution was prepared under stirring, and its mass molar concentration was 6 mmol / kg; 0.1 mol / L~3 mol / L silicon Ester, stand at 15-40°C for self-assembly for 40 minutes; add 25-28% (weight percentage concentration) concentrated ammonia water of 2mol / L-3mol / L to the mixed solution and let it stand for 20-70 minutes , The obtained product is separated by an experimental sieve or a filter membrane, and washed with a large amount of water to obtain a white powdery material, which is observed under an electron microscope as an ultrafine silica tubular material with a diameter of 40-50 nanometers and a hollow tube shape. See figure 2 .

[0054] 2) After the powdery material is naturally dried, it is weighed according to the ratio of 3-5% of the resin content, and then added to a solution of a coupling agent with a certain concentration and ...

Embodiment 3

[0058] According to the steps of Example 1, dissolve 3mmol tartaric acid in the solution of water and ethanol, and prepare template material solution under stirring, and its mass molar concentration is 6mmol / kg; add 0.1mol / L~3mol / L silicic acid under stirring Esters, stand at 15-40°C for self-assembly for 40 minutes; add 25-28% (weight percent concentration) of 2.5mol / L-3.5mol / L concentrated ammonia water to the mixed solution and let it stand for 20-70 Minutes, the obtained product is separated with an experimental sieve or a filter membrane, and washed with a large amount of water to obtain a white powdery material, which is observed under an electron microscope as an ultrafine silica tubular material with a diameter of 80-300 nanometers and a hollow tube shape. See figure 1 .

[0059] 2) After the powdery material is naturally dried, it is weighed according to the ratio of 10% of the resin content, and then added to a solution of a coupling agent with a certain concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com