Microwave dielectric ceramics of perovskite structure and preparation method thereof

A technology of microwave dielectric ceramics and perovskite structure is applied in the field of electronic ceramics, which can solve the problems of high loss of microwave dielectric ceramics, low adjustability of dielectric constant and resonant frequency temperature coefficient, and high sintering temperature. Excellent microwave dielectric properties and the effect of reducing sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] In this embodiment, a microwave dielectric ceramic with a perovskite structure is prepared according to the following method:

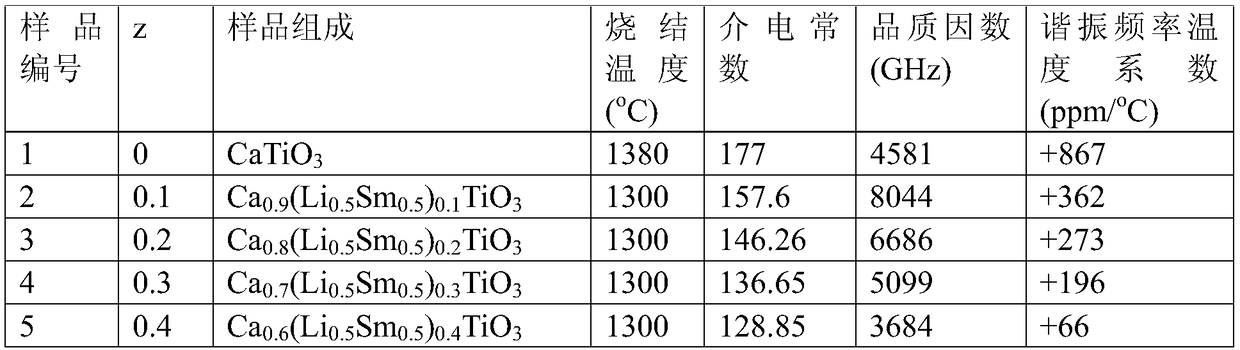

[0068] (1) Mix the calcium carbonate, lithium carbonate, samarium trioxide and titanium dioxide in the formula and perform a ball mill for 6 hours, dry at 110°C, pass through a 60-mesh sieve, put it into a corundum crucible and roast at 1135°C in an air atmosphere , the calcination time is 4h, to get Ca 1-z (Li 0.5 SM 0.5 ) z TiO 3 , take z=0, 0.1, 0.2, 0.3 and 0.4 respectively to carry out the above operations.

[0069] In order to investigate the effect of different z values on Ca 1-z (Li 0.5 SM 0.5 ) z TiO 3 The influence of performance, on the Ca obtained in step (1) 1-z (Li 0.5 SM 0.5 ) z TiO 3 Carry out secondary ball milling for 6 hours, then add polyvinyl alcohol aqueous solution with a mass fraction of 5wt% for grinding, pass through two layers of 120 mesh sieves, press into a cylinder with a diameter of 10 mm and a hei...

Embodiment 8

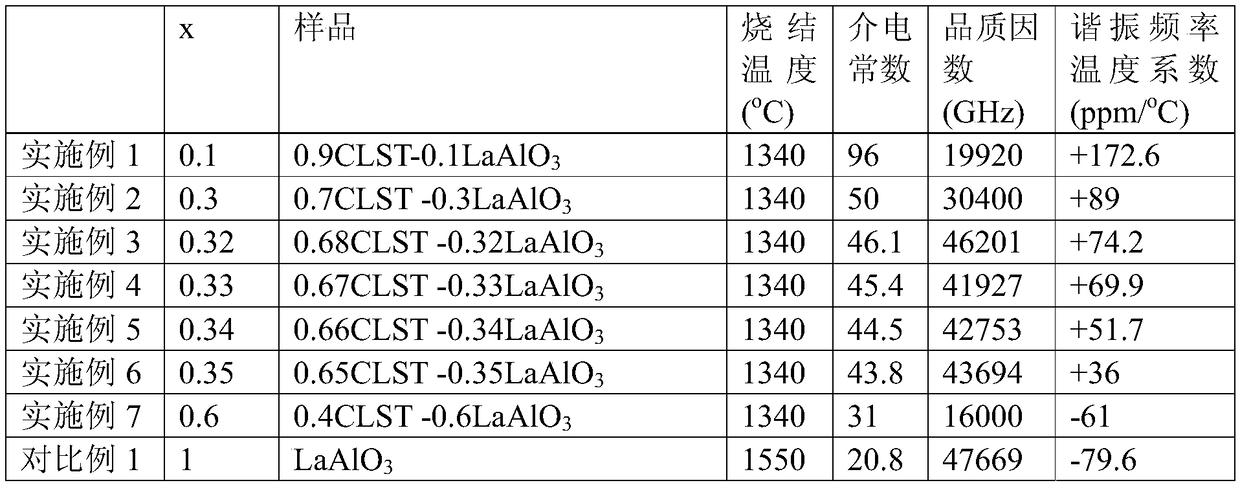

[0085] In this embodiment, a microwave dielectric ceramic with a perovskite structure is prepared according to the following method:

[0086] The Ca of z=0.3 obtained by roasting in the embodiment 1 step (1) of formula quantity 0.7 (Li 0.5 SM 0.5 ) 0.3 TiO 3 Mix it with lanthanum trioxide, samarium trioxide and aluminum sesquioxide and perform a ball mill for 6 hours, dry it at 110°C, pass through a 60-mesh sieve, put it into a corundum crucible and bake it at 1220°C in an air atmosphere for 4 hours , after roasting, carry out secondary ball milling for 6 hours, then add 5wt% polyvinyl alcohol aqueous solution to grind, pass through two layers of 120 mesh sieves, press into a cylinder with a diameter of 10mm and a height of 6mm, and then carry out 1340°C under an air atmosphere. Sintering, sintering 4h into porcelain, obtain the microwave dielectric ceramics (0.68Ca 0.7 (Li 0.5 SM 0.5 ) 0.3 TiO 3 -0.32La 0.95 SM 0.05 AlO 3 ).

[0087] A microwave network analyzer ...

Embodiment 15

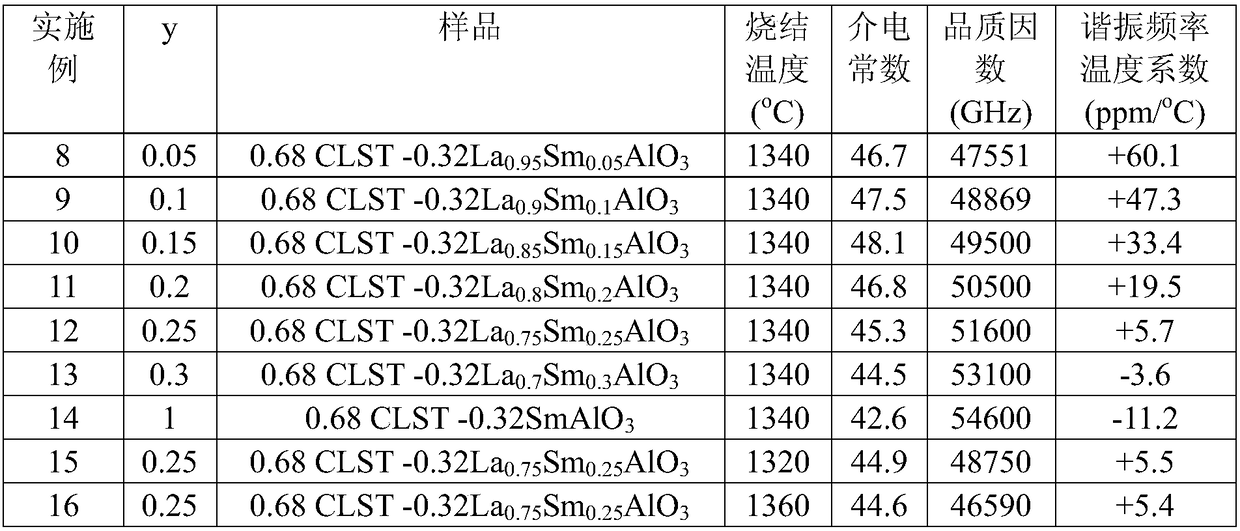

[0090] Example 15 and Example 16 prepared microwave dielectric ceramics with a perovskite structure according to the method of Example 8. The difference is that in step (2), the sintering temperatures are different (see Table 3 for specific temperatures), and the formulas of microwave dielectric ceramics are different. .

[0091] The microwave dielectric properties of the microwave dielectric ceramics prepared in Example 15 and Example 16 were tested using a microwave network analyzer, and the test results are shown in Table 3.

[0092] table 3

[0093]

[0094] In Table 3, CLST stands for Ca 0.7 (Li 0.5 SM 0.5 ) 0.3 TiO 3 .

[0095] It can be seen from Table 3 that in Examples 8-16, the overall performance is optimal when y=0.25.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality factor | aaaaa | aaaaa |

| Resonant frequency temperature coefficient | aaaaa | aaaaa |

| Quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com