Cordierite-based microcrystalline glass material and preparation method thereof

A technology of glass-ceramics and cordierite, which is applied in the field of electronic ceramic materials, can solve the problems of poor matching of silicon chips, large thermal expansion coefficient, and high dielectric loss, and achieve high density, lower sintering temperature, and low dielectric loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

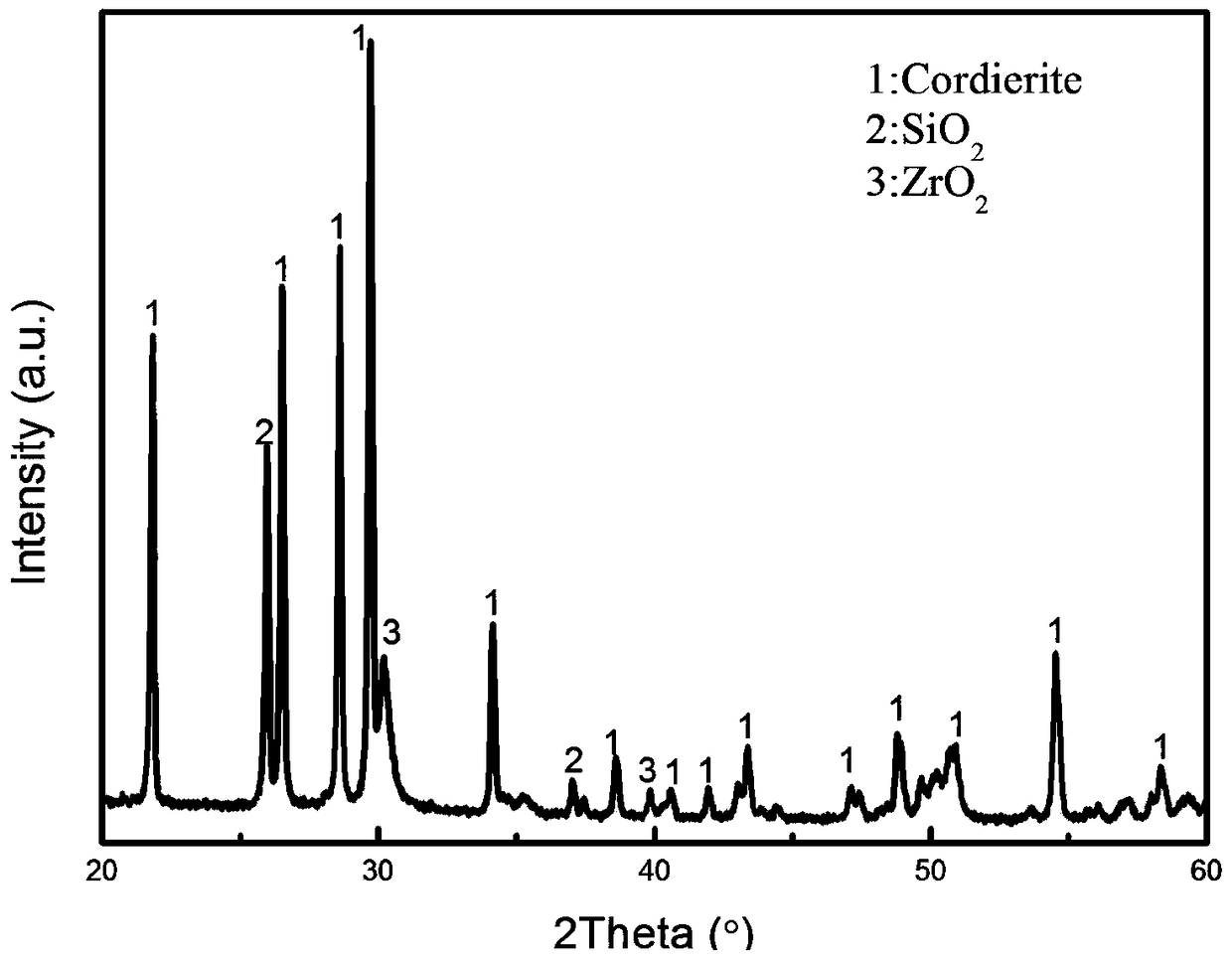

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

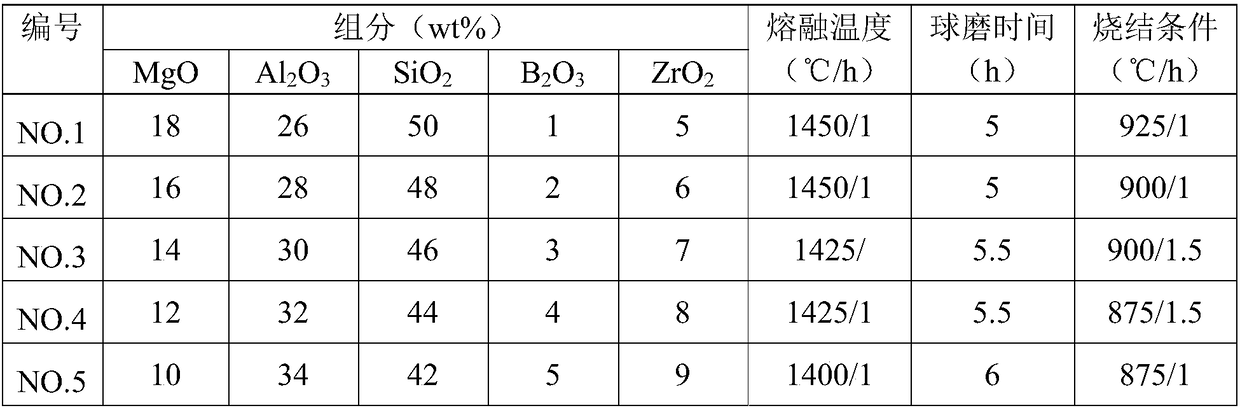

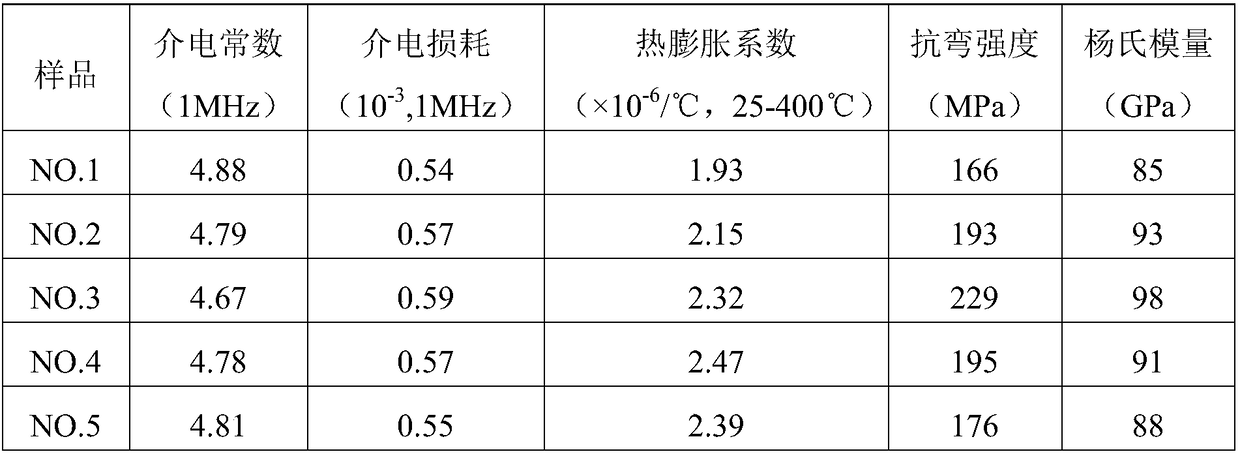

[0020] The present invention provides 5 examples, respectively numbered NO.1-5, wherein the components and sintering conditions of cordierite-based low thermal expansion glass-ceramic materials in each example are shown in the following table:

[0021]

[0022] Concrete preparation process is as follows:

[0023] Accurately calculate the actual amount of the corresponding raw materials according to the mass percentage of each oxide in Table 1 of the design formula, mix and ball mill for 2 hours, mix evenly and dry, put the mixture in a crucible, and melt at a high temperature of 1400-1450°C for 1 hour , the glass slag is obtained after water quenching, and the glass slag is wet ball milled for 5 to 6 hours, then dried and sieved to obtain a uniformly dispersed powder, which is granulated with acrylic acid as a binder, pressed and formed, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com