Graphene/ferroferric oxide composite wave-absorbing material and preparation method thereof

A composite wave-absorbing material, the technology of ferroferric oxide, which is applied in the field of wave-absorbing materials, can solve the problems of polluted environment, low electrical conductivity, and difficulty in film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The embodiment of the present invention provides a method for preparing a graphene / ferric oxide composite wave-absorbing material, comprising the following steps:

[0029] Preparation of graphene oxide dispersion, FeCl 2 solution and FeCl 3 solution;

[0030] Mix the above three liquids, stir and mix at 80-120 degrees (preferably 100 degrees) for 2-3 hours to obtain graphene oxide / Fe 3 o 4 Dispersions;

[0031] The graphene oxide / Fe 3 o 4 The dispersion was dried in vacuum to obtain graphene oxide / Fe 3 o 4 Aerogel;

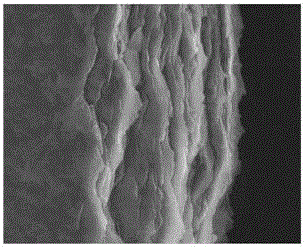

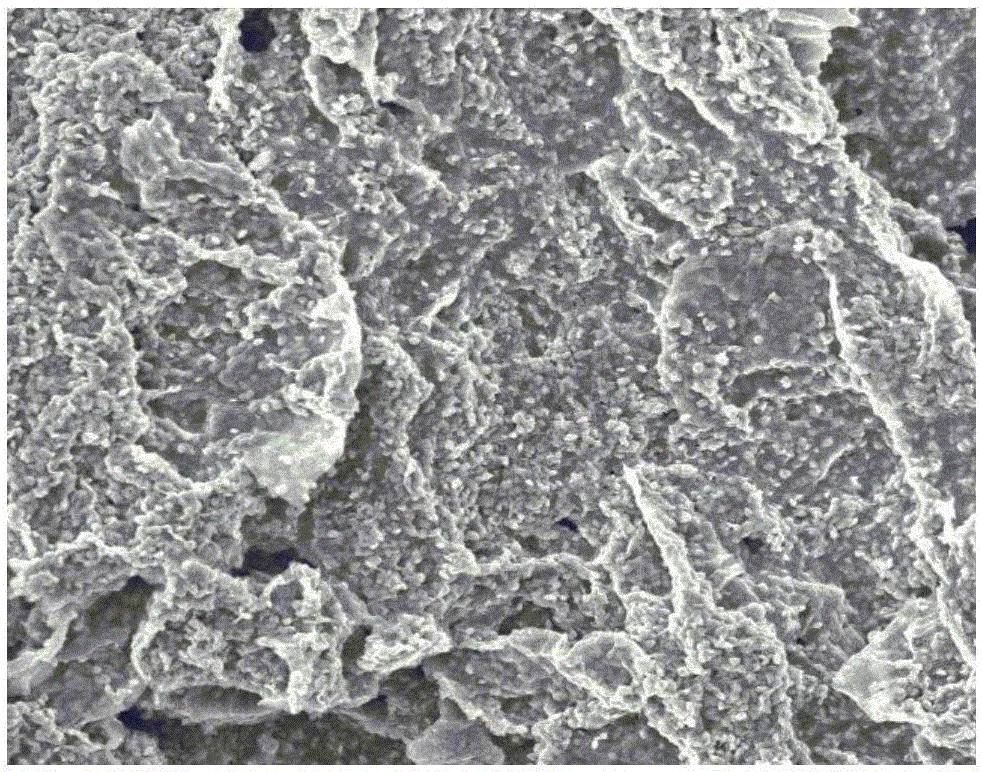

[0032] The graphene oxide / Fe 3 o 4 Airgel heating to obtain graphene / Fe 3 o 4 airgel, the graphene / Fe 3 o 4 Aerogels were mechanically compressed to obtain graphene / Fe 3 o 4 Composite material; the graphene / Fe 3 o 4 Composite materials are layered structures in which sheets are stacked.

[0033] The preparation method of the graphene / ferric oxide composite wave-absorbing material provided by the embodiment of the present invention makes f...

Embodiment 1

[0049] Preparation of graphene oxide: graphene oxide was prepared by the Hummer method, and graphene oxide dispersion was prepared after ultrasonic peeling, with a concentration of 0.8 mg / ml;

[0050] Graphene paper / Fe 3 o 4 Preparation of composite absorbing material:

[0051] Dissolve 0.4g of graphene oxide powder in 100ml of water, ultrasonicate for 35 minutes, and the ultrasonic frequency is 200-300Hz to form a graphene oxide dispersion with a concentration of 4mg / ml;

[0052] Weigh 0.4g FeCl 2 4H 2 O and dissolved in 20ml water, weighed 1g FeCl 3 ·6H 2 O and dissolved in 40ml of water;

[0053] The above prepared solution was added to the graphene oxide solution, stirred at 100 degrees for 2.5 hours to form graphene oxide / Fe 3 o 4 Uniform dispersion (wherein Fe 3 o 4 The content is 25%, Fe 3 o 4 The particle size is 30nm);

[0054] Graphene oxide / Fe 3 o 4 The dispersion was freeze-dried for 24 h under vacuum to form graphene oxide / Fe 3 o 4 Aerogel;

[00...

Embodiment 2

[0058] Preparation of graphene oxide: graphene oxide was prepared by the Hummer method, and a graphene oxide dispersion was prepared after ultrasonic peeling, with a concentration of 7.5 mg / ml;

[0059] Graphene paper / Fe 3 o 4 Preparation of composite absorbing material:

[0060] Dissolve 0.4g of graphene oxide powder in 100ml of water, ultrasonicate for 40 minutes, and the ultrasonic frequency is 200-300Hz, to form a graphene oxide dispersion with a concentration of 4mg / ml;

[0061] Weigh 0.4g FeCl 2 4H 2 O and dissolved in 20ml water, weighed 1g FeCl 3 ·6H 2 O and dissolved in 40ml of water;

[0062] The above prepared solution was added to the graphene oxide solution, stirred at 100 degrees for 3 hours to form graphene oxide / Fe 3 o 4 Uniform dispersion (where Fe 3 o 4 The content is 45%, Fe 3 o 4 The particle size is 45nm);

[0063] Graphene oxide / Fe 3 o 4 The dispersion was freeze-dried for 24 h under vacuum to form graphene oxide / Fe 3 o 4 Aerogel;

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com