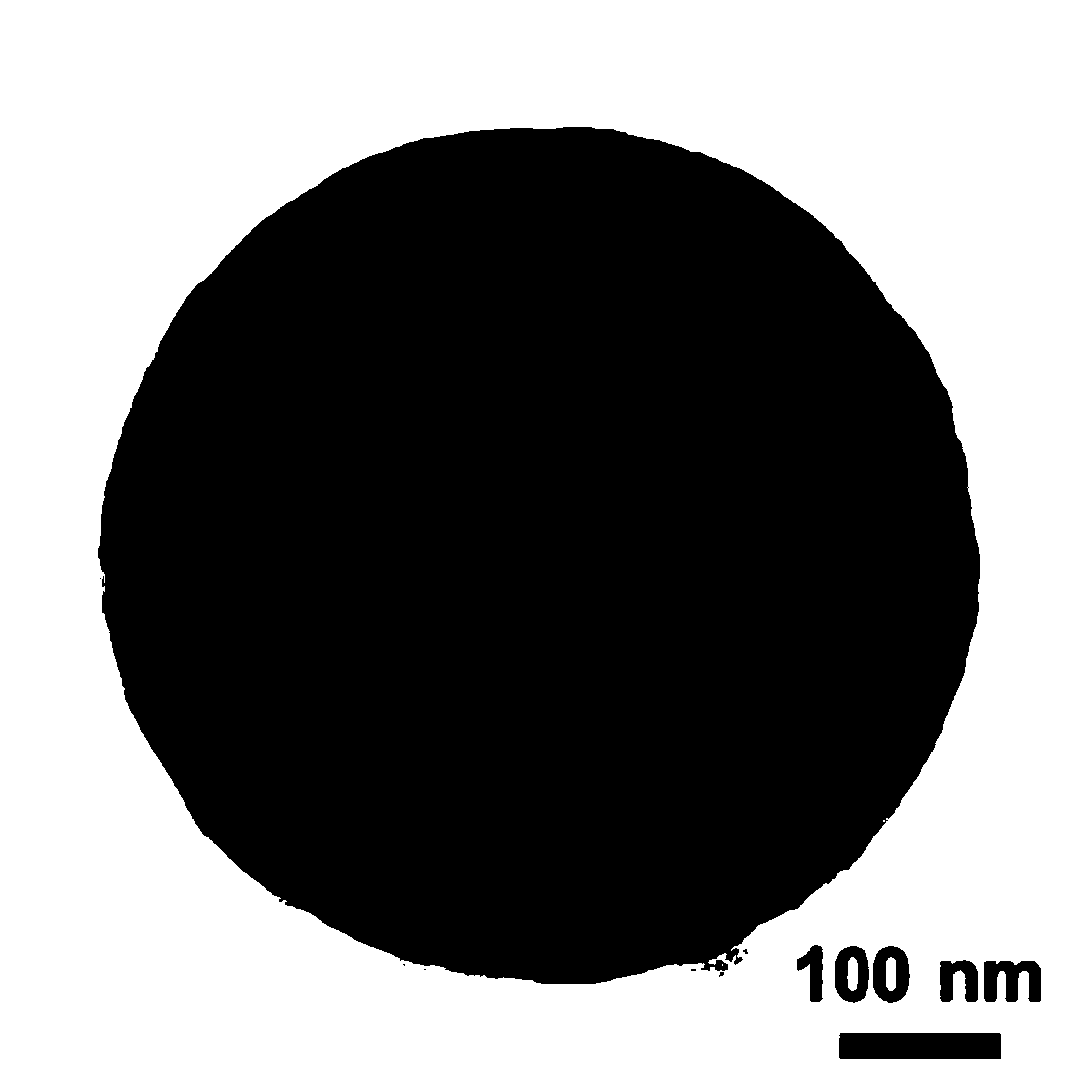

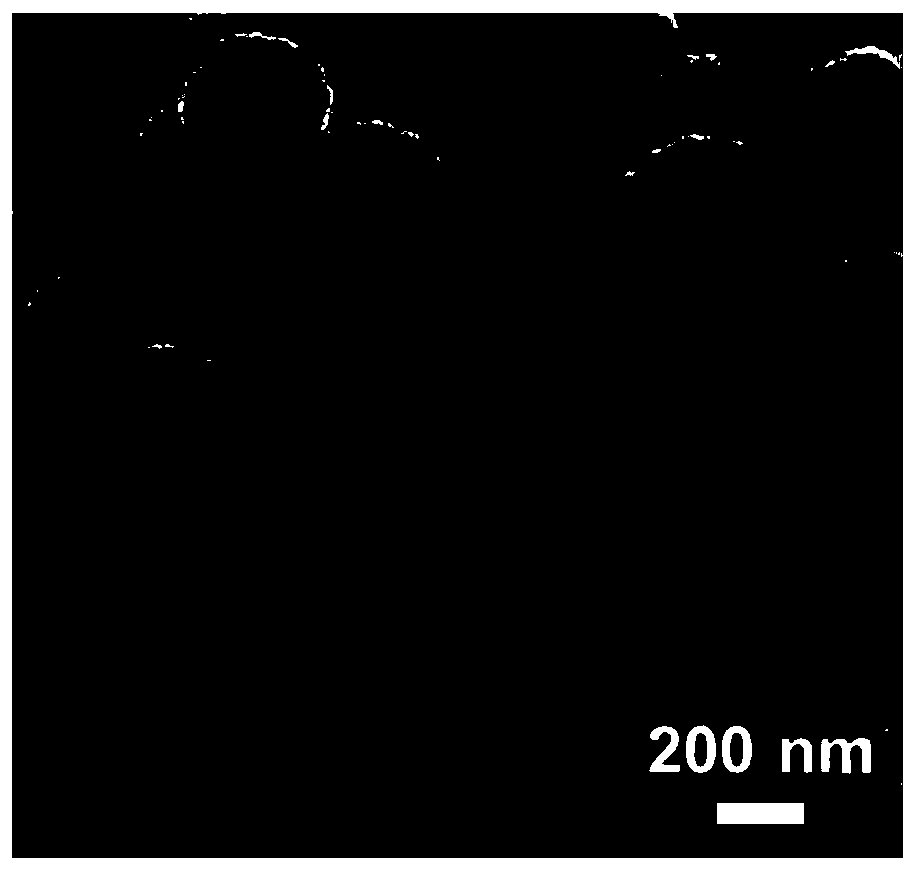

Preparation method of silicon carbide/carbon hollow porous microsphere wave-absorbing material

A technology of porous microspheres and wave-absorbing materials, applied in the field of wave-absorbing materials, can solve the problems of large particle size and easy agglomeration of silicon carbide particles, and achieve the effects of small size, uniform dispersion and uniformity guarantee.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0031] Specific implementation mode 1: In this implementation mode, a method for preparing a silicon carbide / carbon hollow porous microsphere microwave-absorbing material is specifically carried out according to the following steps:

[0032] 1. Mix deionized water, absolute ethanol and ammonia water, then add surfactant, stir to dissolve, then add resorcinol and stir to dissolve, then add silicon source and formaldehyde solution and stir at room temperature, then add melamine, at room temperature Stir to obtain a mixture;

[0033] 2. Transfer the mixture obtained in step 1 to a high-temperature and high-pressure reactor for reaction, then centrifuge, wash, dry, and perform high-temperature calcination under a nitrogen atmosphere to obtain a silica / carbon composite powder;

[0034] 3. Mix and grind the silicon dioxide / carbon composite powder and magnesium powder obtained in step 2 evenly, transfer to a tube furnace, perform high-temperature calcination under nitrogen atmosphere...

specific Embodiment approach 2

[0035] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the volume ratio of deionized water, absolute ethanol and ammonia water in step 1 is 500:200:3. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0036] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass fraction of ammonia water in step 1 is 25%. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com