Li-Nb-Ti-based microwave dielectric ceramic material

A technology of microwave dielectric ceramics and raw materials, applied in the field of dielectric ceramics, can solve the problems of high slurry viscosity, inability to co-fire, instability, etc., and achieve the effect of reducing the sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

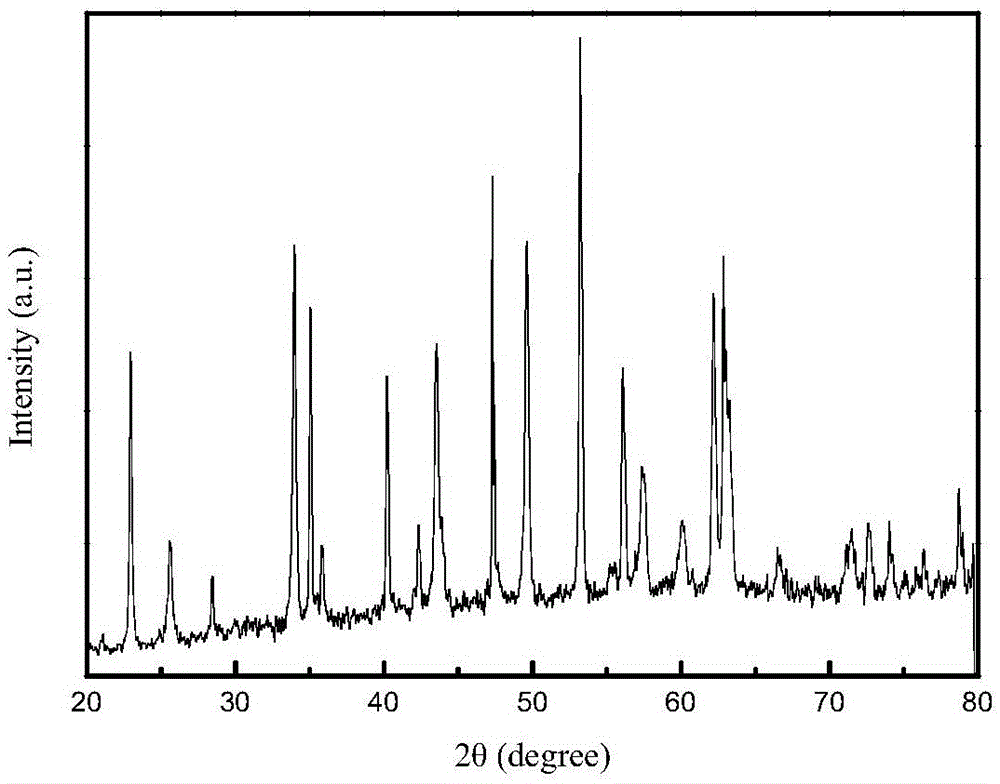

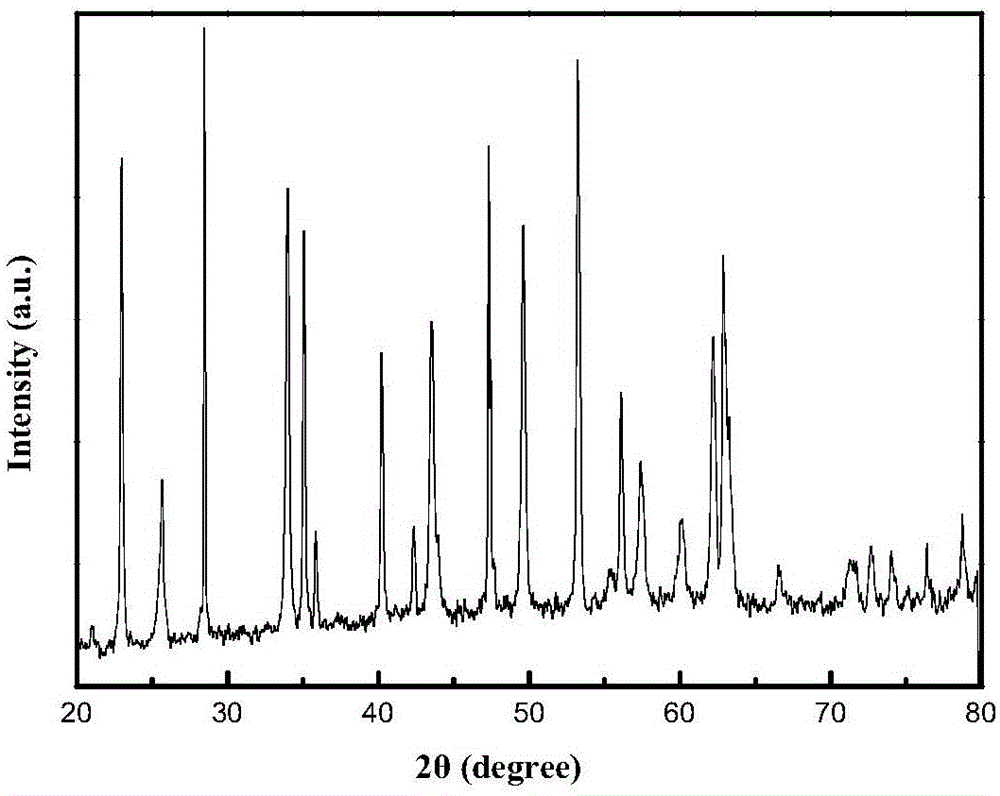

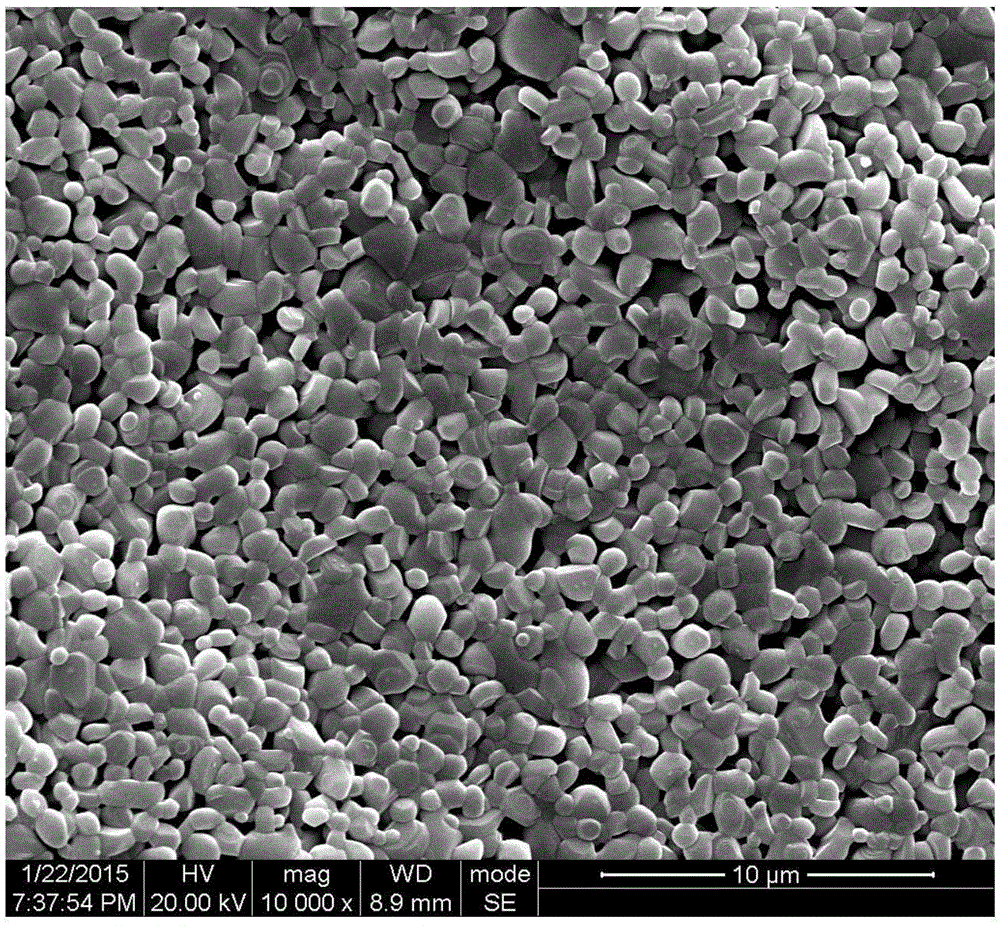

Image

Examples

Embodiment

[0024] The material of the invention is composed of a lithium niobium titanium series material and a glass heat reducer accounting for 0.5-6.0% by weight of the main crystal phase, and the material of the invention can be obtained through solid state reaction. The composition of lithium niobium titanium series material is Li a Nb b Ti c o 3 Wherein: a=11, b=3, c=6. The raw materials for glass fever reducer include: lithium carbonate (Li 2 CO 3 ), zinc oxide (ZnO), aluminum oxide (Al 2 o 3 ), silicon dioxide (SiO 2 ), boron trioxide (B 2 o 3 ) and trace additive components. Table 1 shows the data of several specific examples of the composition content of the present invention, and Table 2 shows the microwave dielectric properties of each example. The preparation method is as above, and the microwave dielectric performance is evaluated by the cylindrical dielectric resonator method, and the detection method is the GB / T7265.2-1987 open cavity method.

[0025] Table 1:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com