Radial sliding bearing test bed with elastic support

A technology of radial sliding and elastic support, applied in the direction of mechanical bearing testing, etc., can solve the problems of inconvenient bearing working load, experimental bearing type and structural form limitations, inability to replace experimental bearings, etc., to avoid the effect of influence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

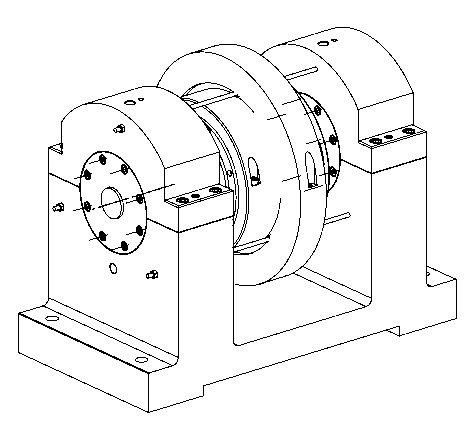

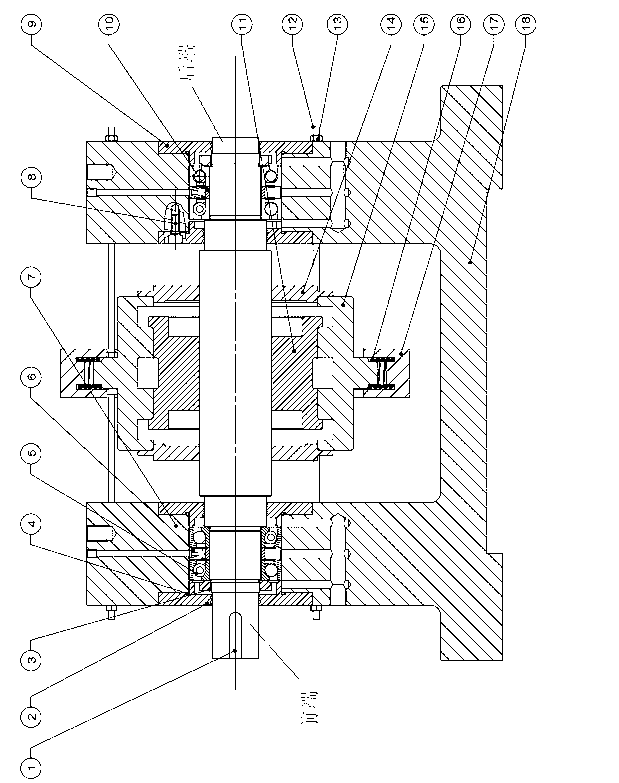

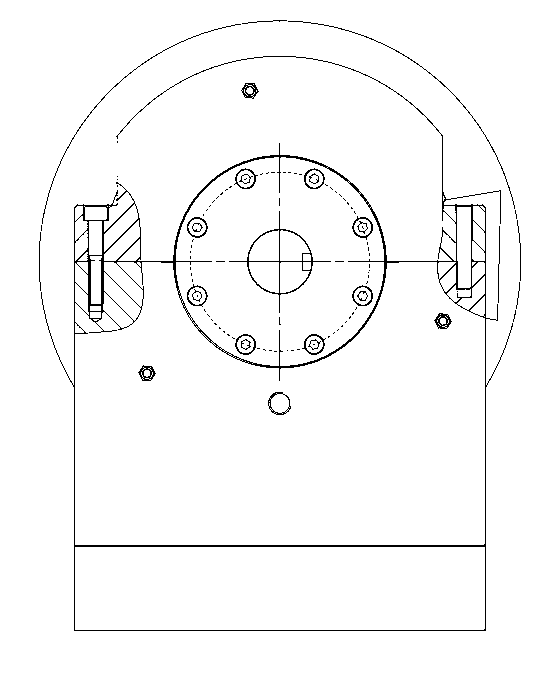

[0021] see Figure 1 to Figure 4 , the radial sliding bearing test bench with elastic support includes a test bench base, a support device, a main shaft (1), an experimental bearing, an injection device and a main shaft positioning device, and is characterized in that: the front end of the main shaft (1) has a The keyway can be connected to an external drive system; the front-end support device is: a pair of back-to-back mounted angular contact bearings (5), the inner rings of the two angular contact bearings (5) are composed of a lock nut (3) and a positioning ring ( 10) Fixed on the stepped surface of the main shaft (1), the outer rings of the two angular contact bearings (5) are fixed on a test bench base (18) and a test bench top cover ( 7), the rolling bearing end cover (2) is fixed on the base of the test bench (18) and the upper cover of the test bench (7) by the hexagon socket head cap screw (8); the outer ring of the two angular contact bearings (5) is sandwiched by a...

Embodiment 2

[0023] This embodiment is basically the same as Embodiment 1, and the special features are as follows: the base of the test bench is composed of the base of the test bench (18), the upper cover of the test bench (7) and the bearing end cover (2, 9); The upper cover (7) of the table has an oil inlet passage, and the oil inlet is a round mouth, which is processed with a fine thread to facilitate the connection of the lubricating oil pipe. The base (18) of the test bench has an oil return passage, which is also round. The mouth is processed with fine thread to connect the oil return pipe; the base is engraved with a reference bar, which is convenient for the installation of the experimental bearing and the measurement of the experimental results. The bearing end cover (2, 9) is divided into the front bearing end cover (2) and the rear End bearing cover (9), the two structures are slightly different, the front end bearing cover (2) is in contact with the front end support bearing f...

Embodiment 3

[0025] Such as figure 2As shown, in the radial sliding bearing test bench with elastic support, there is a keyway at the front end of the main shaft (1), which can be connected to an external drive system. The inner ring of (5) is fixed on the stepped surface of the main shaft by the lock nut (3) and the positioning ring (10), and the outer rings of the two angular contact bearings (5) are fixed on the experimental surface by two rolling bearing end covers (2). On the platform base (18) and the upper cover of the experimental platform (7), the rolling bearing end cover (2) is fixed on the experimental platform base by the hexagon socket head screw (8), and the outer ring of the two angular contact bearings (5) sandwiches a The injection ring (6) with the same width as the positioning ring (10), the support and fixing method of the rear end of the inverted high-speed radial sliding bearing test bench spindle (1) are basically the same as the front end, the only difference lies...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com