Lubricating grease composition for automobile door opening stoppers and preparation method thereof

A technology of grease composition and automobile door, which is applied in the field of grease, can solve problems such as low temperature of grease, and achieve good technical effects and good low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

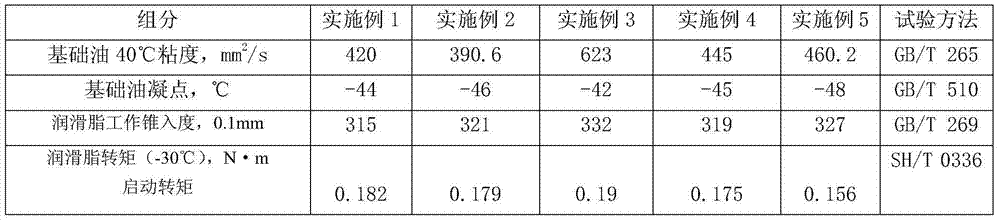

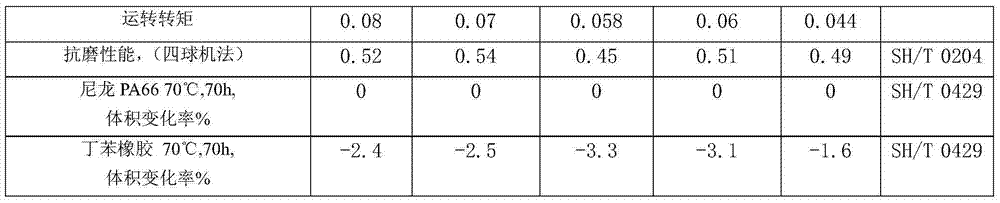

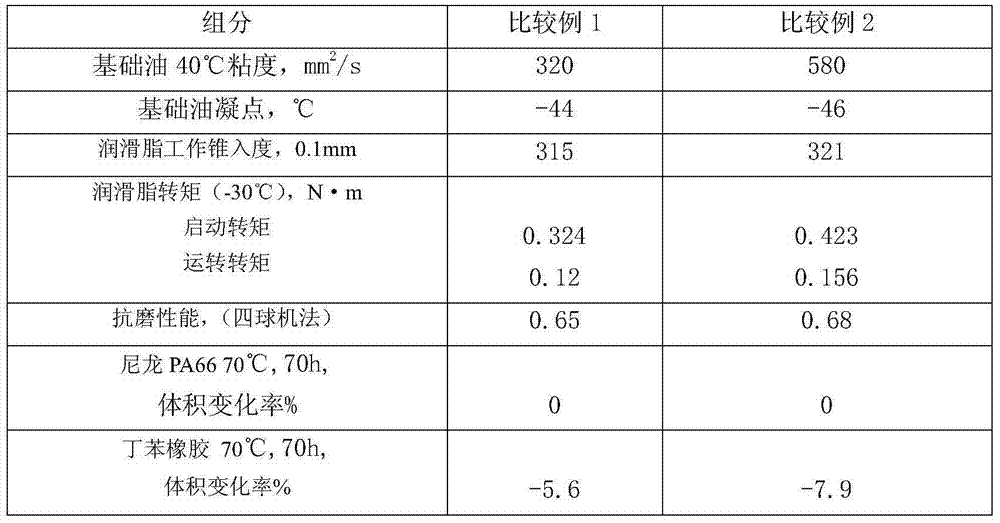

Examples

Embodiment 1

[0037] Thickener percentage: 7%, base oil content: 89%, benzotriazole content: 0%, polytetrafluoroethylene content: 0.2%, boron nitride content: 2%, nano calcium carbonate content: 1% , Melamine cyanurate content: 0.8%, diisooctyl diphenylamine content: 0.5%, tert-butyl p-cresol content: 0.5%.

[0038] Put 70 grams of 12-hydroxylithium stearate and 534 grams of base oil into the reactor, stir and heat to 210°C, add 178 grams of base oil into the reactor, continue stirring, add 178 grams of base oil, and stir. Cool down to 80°C, add 2 grams of polytetrafluoroethylene, 10 grams of boron nitride, 10 grams of nano calcium carbonate, 8 grams of melamine cyanurate, 5 grams of diisooctyl diphenylamine, 5 grams of tert-butyl p-cresol , stir. The composition is oil-pressed three times by a three-roller machine, and then packed in a finished product.

Embodiment 2

[0040] Thickener percentage content: 10%, base oil content 84%, benzotriazole content: 0%, polytetrafluoroethylene content: 1%, boron nitride content: 1.2%, nano calcium carbonate content: 0.8% , Melamine cyanurate content: 0.8%, diisooctyl diphenylamine content: 1%, tert-butyl p-cresol content: 1%.

[0041] Put 100 grams of 12-hydroxylithium stearate and 300 grams of base oil into the reactor, stir and heat to 210°C, add 340 grams of base oil into the reactor, continue stirring, add 200 grams of base oil, and stir. Cool down to 80°C, add 10 grams of polytetrafluoroethylene, 12 grams of boron nitride, 8 grams of nano-calcium carbonate, 10 grams of melamine cyanurate, 10 grams of amine antioxidant and 10 grams of amine antioxidant, stir . The composition is oil-pressed three times by a three-roller machine, and then packed in a finished product.

Embodiment 3

[0043] Thickener percentage content: 7%, base oil content 88%, polytetrafluoroethylene content: 0.5%, boron nitride content: 0.7%, nano calcium carbonate content: 0.8%, melamine cyanurate content: 0.5% , Diisooctyl diphenylamine content: 1%, tert-butyl p-cresol content: 1%, barium dinonyl naphthalene sulfonate content: 0.5%.

[0044]Put 70 grams of 12-hydroxylithium stearate and 480 grams of base oil into the reactor, stir and heat to 210°C, add 200 grams of base oil in the reactor and cool it to 180°C, continue stirring, add 200 grams of base oil and stir Cool down to 80°C, add 5 grams of polytetrafluoroethylene, 7 grams of boron nitride, 8 grams of nano-calcium carbonate, 5 grams of melamine cyanurate, 10 grams of diisooctyl diphenylamine, 10 grams of tert-butyl p-methyl Phenol and 5 g of basic barium dinonylnaphthalenesulfonate, stirred. The composition is oil-pressed three times by a three-roller machine, and then packed in a finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com