Lubricant composition for four-stroke motorcycle engine

A technology of lubricating oil composition and motorcycle, applied in the direction of lubricating composition, petroleum industry, additives, etc., to achieve the effect of good high temperature cleaning and excellent anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-4

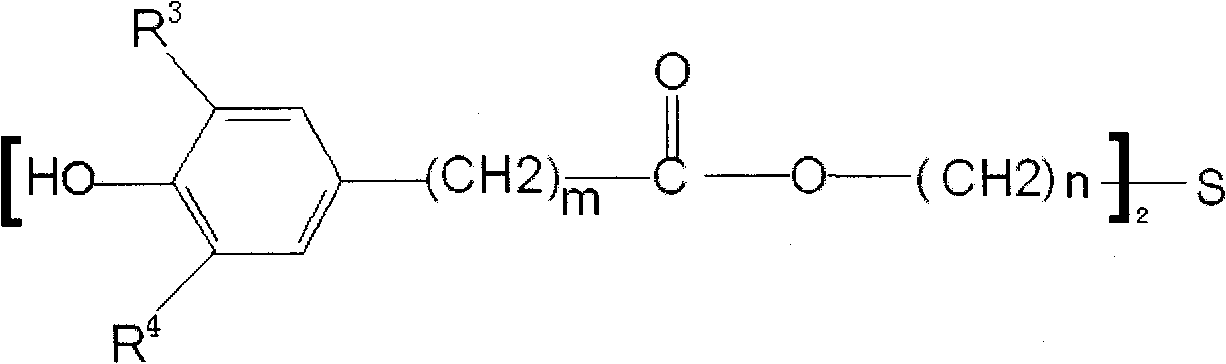

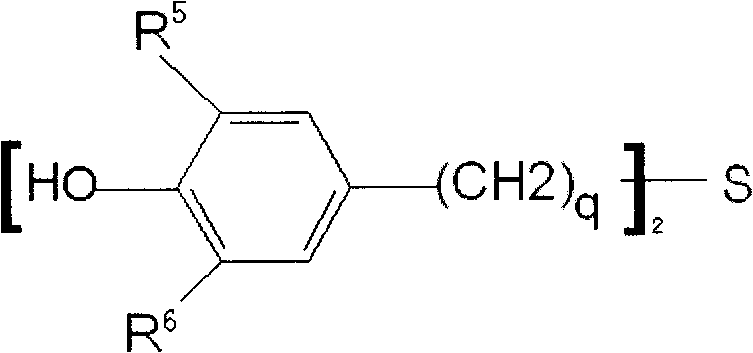

[0056] Add antioxidants T534, 1035, and methylidene 4426-S in proportion to the mixing container, heat at 60℃-90℃ under normal pressure, and stir for 1 hour to 2 hours to obtain a uniform transparent light yellow viscous liquid. The component A of the invention is a compound antioxidant. The composition ratio (mass fraction) of preparation examples 1-4 of the composite antioxidant is shown in Table 1.

[0057] Table 1

[0058] Serial number

Embodiment 1

[0060] Examples 1-5 are the composition and main properties of the lubricating oil composition of the present invention. The components are added to a blending container in proportion, heated at 45°C-80°C under normal pressure, and stirred for 1 hour to 2 hours to prepare a lubricating oil composition for a four-stroke motorcycle engine with a viscosity grade of 10W-40. In Comparative Examples 1, 2, and 3-1, single-component antioxidants were added, namely T534, 1035, and methylidene 4426-S. In Comparative Examples 3-2, a two-component prepared by the patent CN100460490C method was added. Compound antioxidants, in which Example 1 and Comparative Example 1, Example 2 and Comparative Example 2 have all the same formula composition except for the antioxidant, and Example 3 and Comparative Examples 3-1, 3-2 also have All the same formula composition except for antioxidants. The composition ratios (mass fractions) of Example 1-5 and Comparative Examples 1, 2, 3-1, and 3-2 are shown...

Embodiment 6-9

[0070] Examples 6-9 are the lubricating oil compositions of the four-stroke motorcycle engine with a viscosity grade of 10W-40 according to the present invention. The spot dispersion test was performed on Examples 6-9, and the formula composition and dispersion test results are shown in Table 5. Among them, the mixture of polyisobutylene succinimide and polyisobutylene succinate pentaerythritol ester was added in Examples 6 and 7, and the one-component dispersant was added in Examples 8 and 9.

[0071] table 5

[0072]

[0073] The spot dispersion test method is to add 30% program VG engine sludge to the test oil, ultrasonically disperse for 6 minutes, heat in an oven at 200°C for 2 hours, then drop the oil on the filter paper, and measure the diameter of the oil spot dispersion circle and the sludge diameter after 24 hours The ratio is the dispersion index. The higher the dispersion index, the better the dispersion of the oil.

[0074] It can be seen from the results in Table 5 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com