Boat plunger-type engine lubricating oil composition

A lubricating oil composition, plunger type technology, applied in the direction of lubricating composition, petroleum industry, additives, etc., can solve the problem of not being able to use lubricating oil together, and achieve enhanced anti-oxidation performance, good anti-rust performance, and good lubricating performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

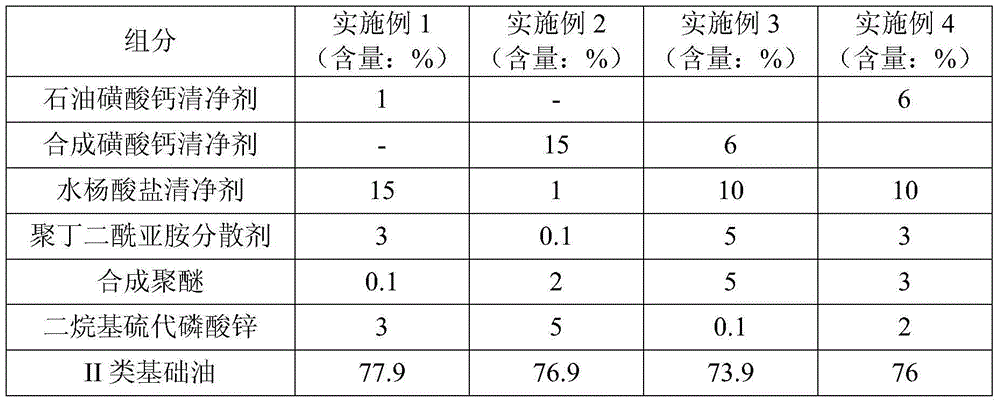

[0027] The components and contents of the lubricating oil composition in each embodiment are shown in Table 1. Embodiment 1-4 and comparative example are carried out into coke plate experiment and PDSC constant temperature method to measure oxidation induction period experiment respectively, concrete test conditions are as follows:

[0028] 1) Coke formation test: Experimental instrument specification model: Koehler coke formation tester (FTM 791-3462); oil temperature: 310°C; plate temperature: 110°C; turn-on-stop ratio: 20 / 40; experiment time: 3h; Refueling volume: 300mL.

[0029] 2) PDSC constant temperature method to determine the oxidation induction period experiment: Experimental instrument specification model: differential scanning calorimeter (Q20P); temperature: 190°C; oxygen pressure: 2.5MPa; oxygen flow rate: no flow rate (static); material of the sample dish And diameter: 4mm×5mm; sample dosage: 3±0.2mg.

[0030] The experimental results are shown in Table 2.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com