Engine crankshaft balance shaft mechanism

A balance shaft and engine technology, applied in the direction of inertial force compensation, etc., can solve the problems of insufficient compact structure, large amplitude of the balance shaft system, etc., and achieve the effects of compact structure, reduced noise, and simplified tensioning mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

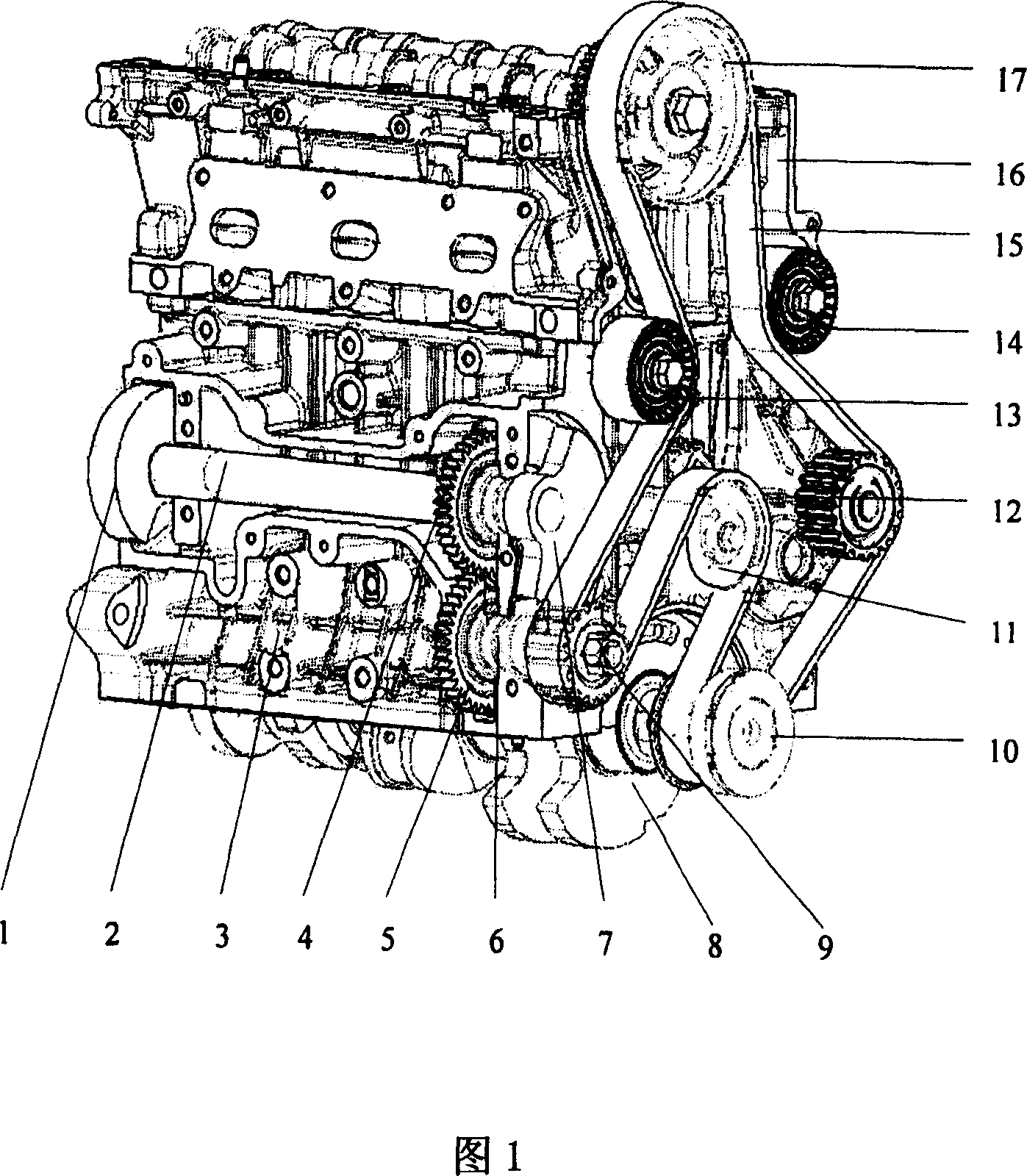

[0016] In the embodiment shown in Fig. 1, a kind of engine crankshaft balance shaft mechanism comprises the balance shaft 2, drive shaft 6, drive shaft 6, Gears 4, 5, balance shaft cover; balance shaft gear 4 is installed on the front end of balance shaft 2, and balance shaft gear 4 meshes with balance shaft gear 5 on drive shaft 6; balance shaft 2 is installed on the side of cylinder body 3; driven by timing belt 15 shaft 6, and drives the balance shaft 2 through the meshing balance shaft gears 4,5.

[0017] As shown in Figure 1, inside the cylinder head 16, the timing belt 15 installed on the crankshaft timing gear 10 on the crankshaft 8 passes through the belt tensioner 11, the belt gear 9, the idler 13, and the camshaft timing gear 17 in sequence. , idler wheel 14, water pump gear 12 form belt transmission chain.

[0018] An oil hole can also be drilled in the middle of the balance shaft, and then one end is blocked, and a corresponding lubricating oil groove is added to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com