Ester-type fire resistant hydraulic oil and production method thereof

A hydraulic oil and flame retardant technology, applied in the field of hydraulic oil, can solve the problems of short oil change period, easy oxidation and deterioration, and poor concord performance, so as to achieve low oil use cost, improve anti-oxidation performance, and improve extreme pressure performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation steps of sulfurized oleic acid TMP ester:

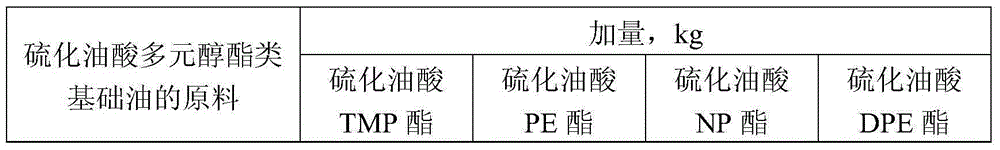

[0038] Add 100 kg of TMP oleate, 3 kg of sulfur powder and 10 kg of activated carbon into a heated, stirred, and sealed reaction kettle and stir evenly. Stir and heat to 150°C±5°C under nitrogen protection, and react at constant temperature for 3 hours. Then cool down to 120°C±5°C and filter. The product after filtering obtains sulfurized oleic acid TMP ester base oil after decolorizing with 5 kilograms of active clays again. The analytical data of gained sulfurized oleic acid TMP ester is shown in Table 1.

[0039] The preparation process of sulfurized oleic acid, sulfurized oleic acid NP ester, sulfurized oleic acid DPE ester is the same as the preparation steps of sulfurized oleic acid TMP ester, the difference is that the raw material types and composition ratios are different, and the obtained sulfurized oleic acid polyol esters The analytical data of the base oil are shown in Table 1.

[0040] Table 1 ...

Embodiment 1-5

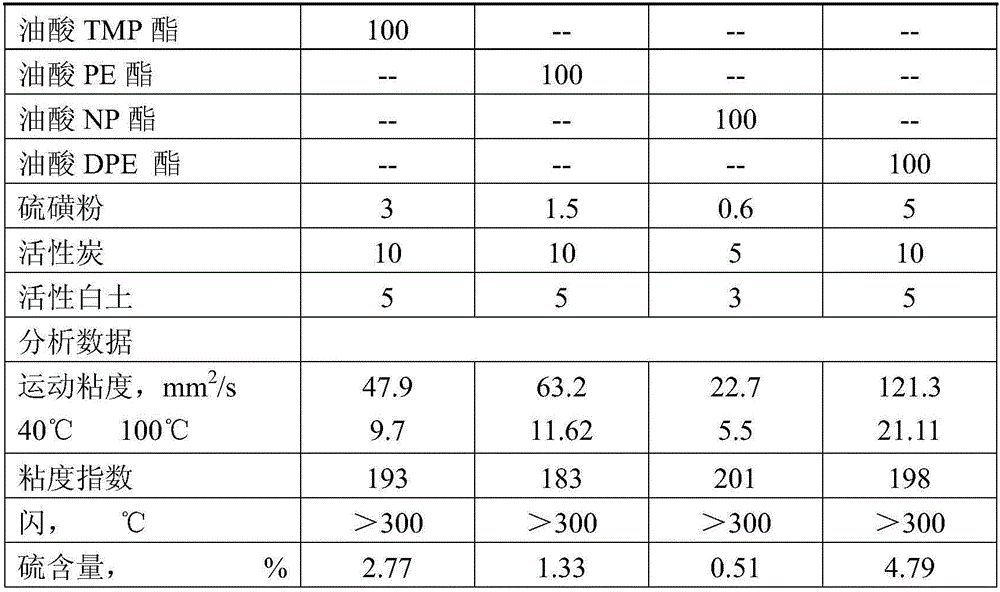

[0044] The formula composition of embodiment 1-5 ester type flame retardant hydraulic oil is shown in Table 2, and the preparation method is the same, as follows:

[0045] Put the vulcanized animal and vegetable oleic acid polyol ester compound base oil into the reaction kettle, heat to 100-120°C, then add antioxidant, dissolve at constant temperature and stir evenly, then cool down to 80-100°C, add other additives, and stir at constant temperature for 1 Hours, stop heating, take samples for analysis, filter and pack the finished product after the quality reaches the target.

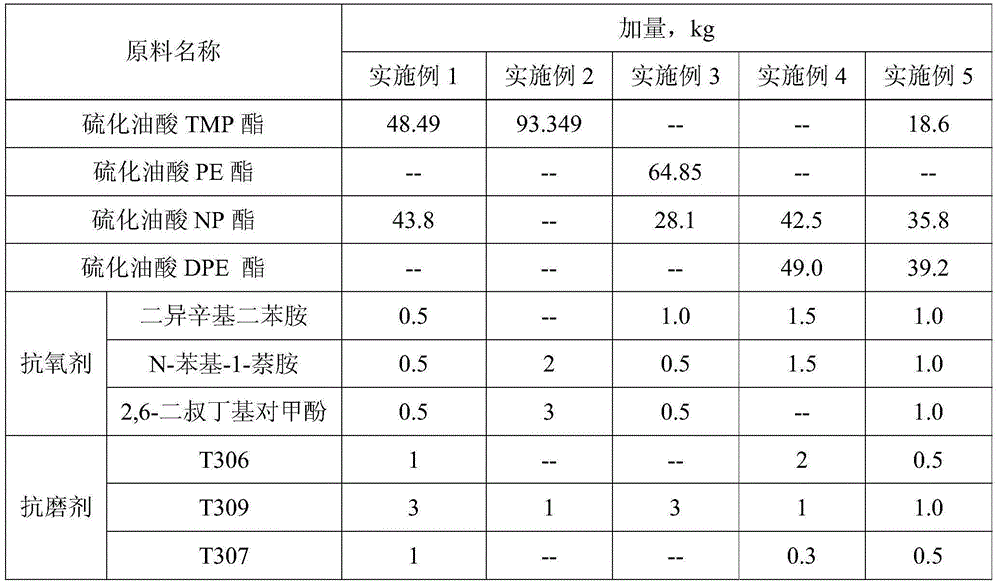

[0046] See Table 3 for the formula, performance and comparison of the ester-type flame retardant hydraulic oil of Examples 1-5.

[0047] Table 2 The formula composition of embodiment 1-5 ester type flame retardant hydraulic oil

[0048]

[0049]

[0050] Table 3 The analysis data of embodiment 1-5 ester type flame retardant hydraulic oil

[0051]

[0052]

[0053] Conventional fire-resistan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com