Single body fuel injection pump self-lubricating tappet body roller

A fuel injection pump, self-lubricating technology, used in fuel injection pumps, components of pumping devices for elastic fluids, pump components, etc., can solve problems such as cam and roller wear, major failures, ablation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiments of the present invention will be described below with reference to the accompanying drawings.

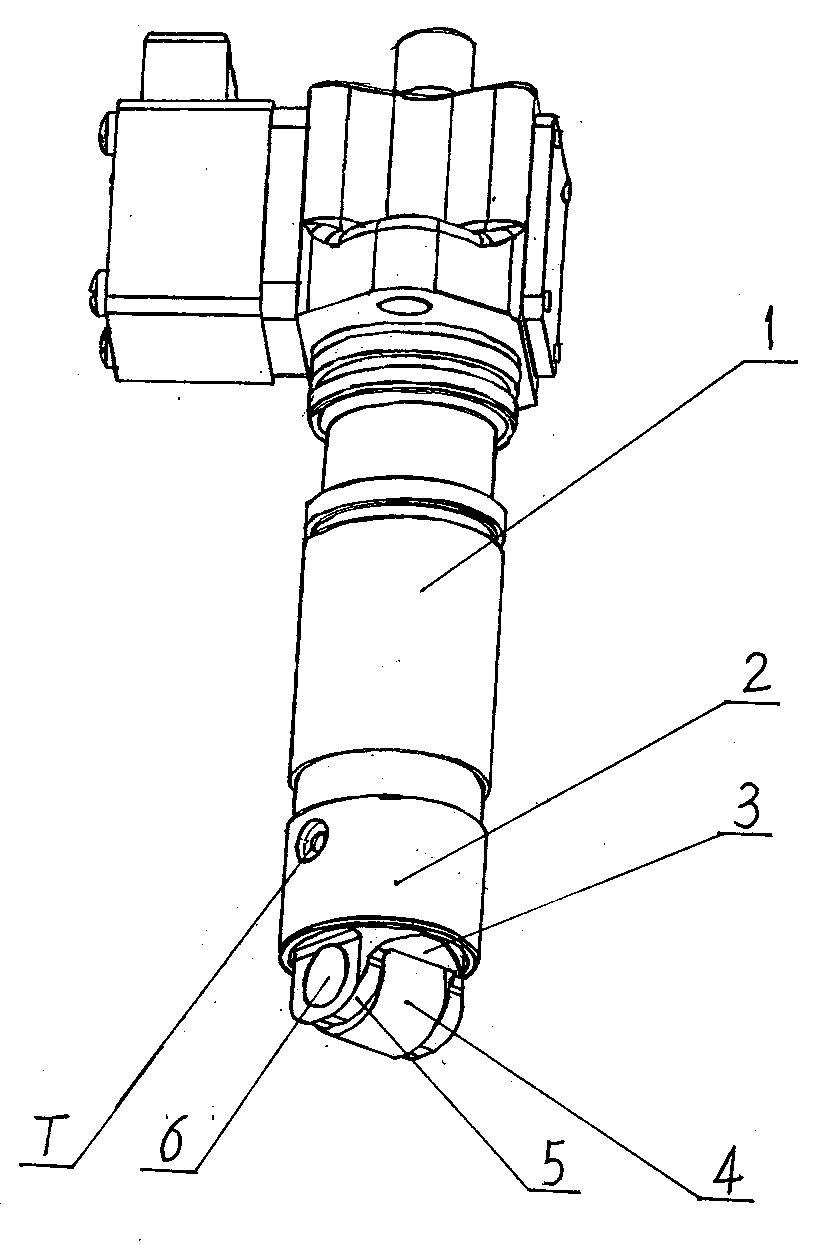

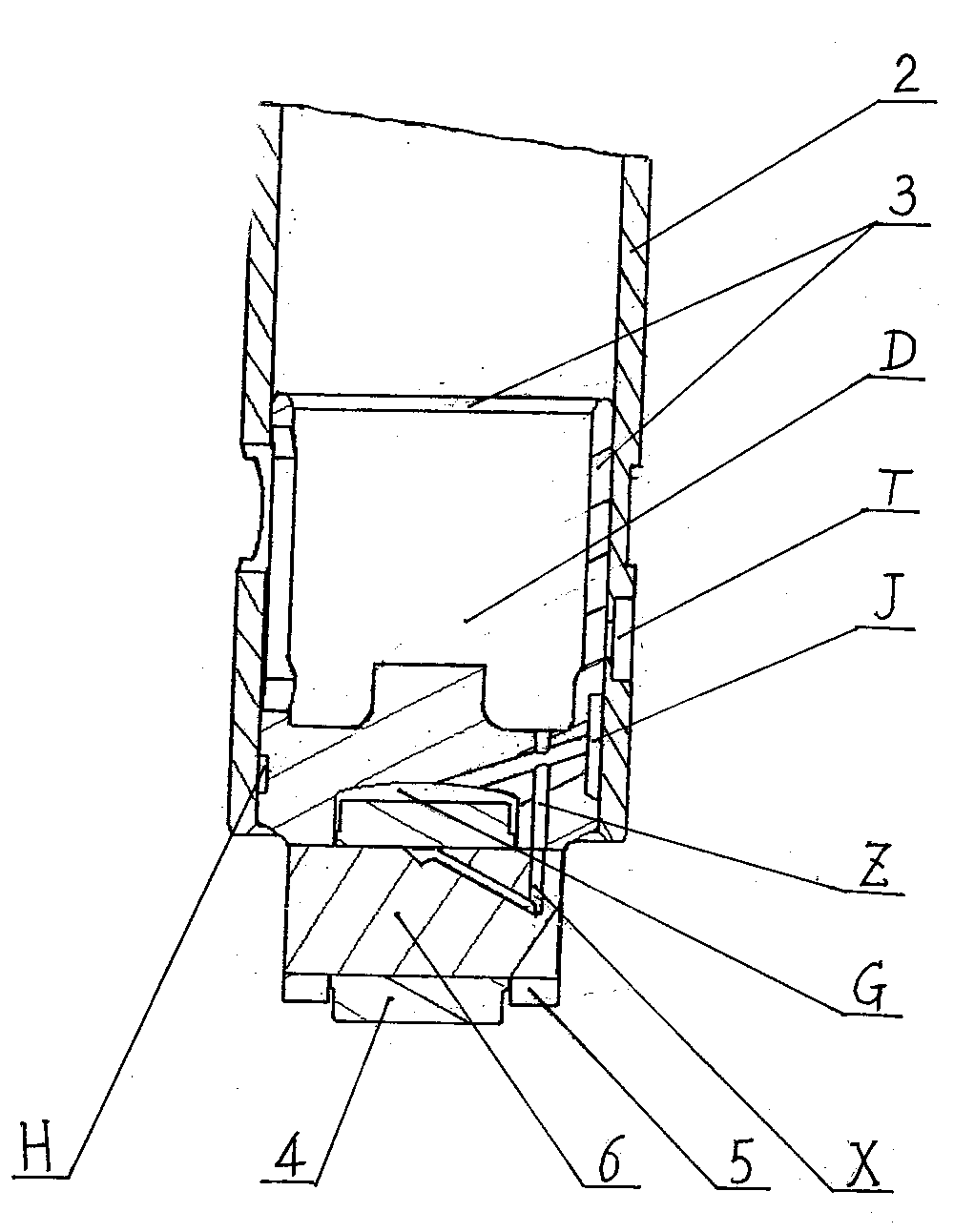

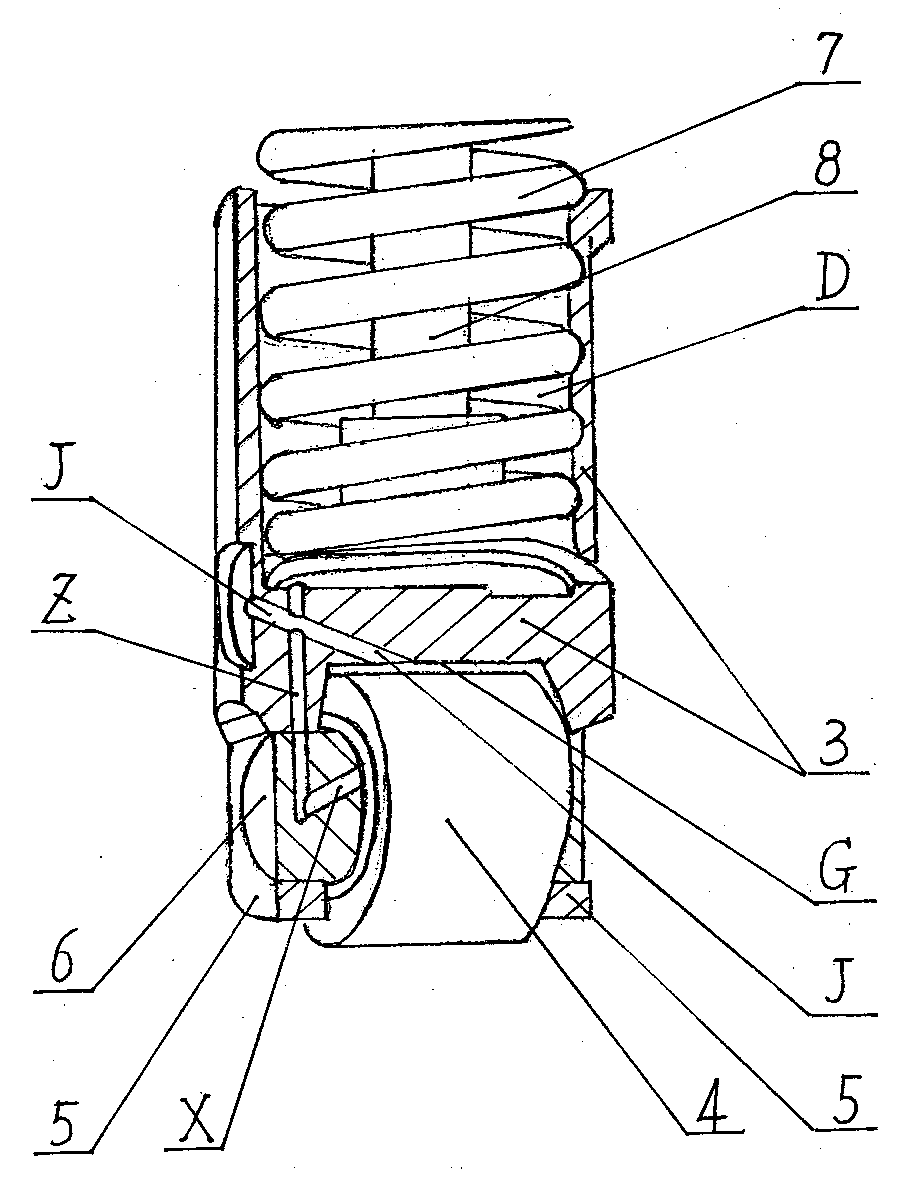

[0014] see figure 1 , figure 2 , image 3 , the lower end of the pump body of the fuel injection pump 1 is equipped with a tappet sleeve 2, the tappet sleeve 2 is equipped with a tappet body 3, the lower end of the tappet body 3 is a roller bracket 5, and the roller pin holes K on both sides of the roller bracket 5 are equipped with roller pins 6 , the roller 4 is sleeved on the roller pin 6 and is arranged in the roller chamber G in the middle of the roller bracket 5 . The tappet sleeve oil inlet hole T is opened on the outer cylindrical surface of the tappet sleeve 2, and the tappet body oil inlet hole J is opened on the outer cylindrical surface of the tappet body 3. The tappet body oil inlet hole J is connected with the roller chamber G, and is connected to the roller chamber G. It intersects and communicates with the axial lubricating oil cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com