Wear-resistant resin lens and preparation method thereof

A wear-resistant resin and lens technology, applied in the field of glasses, can solve the problems of inconspicuous anti-fouling and hardening effect, easy detachment of film, poor hardening effect of lenses, etc., achieves excellent anti-wear properties, simple preparation method, and reduced number of times Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

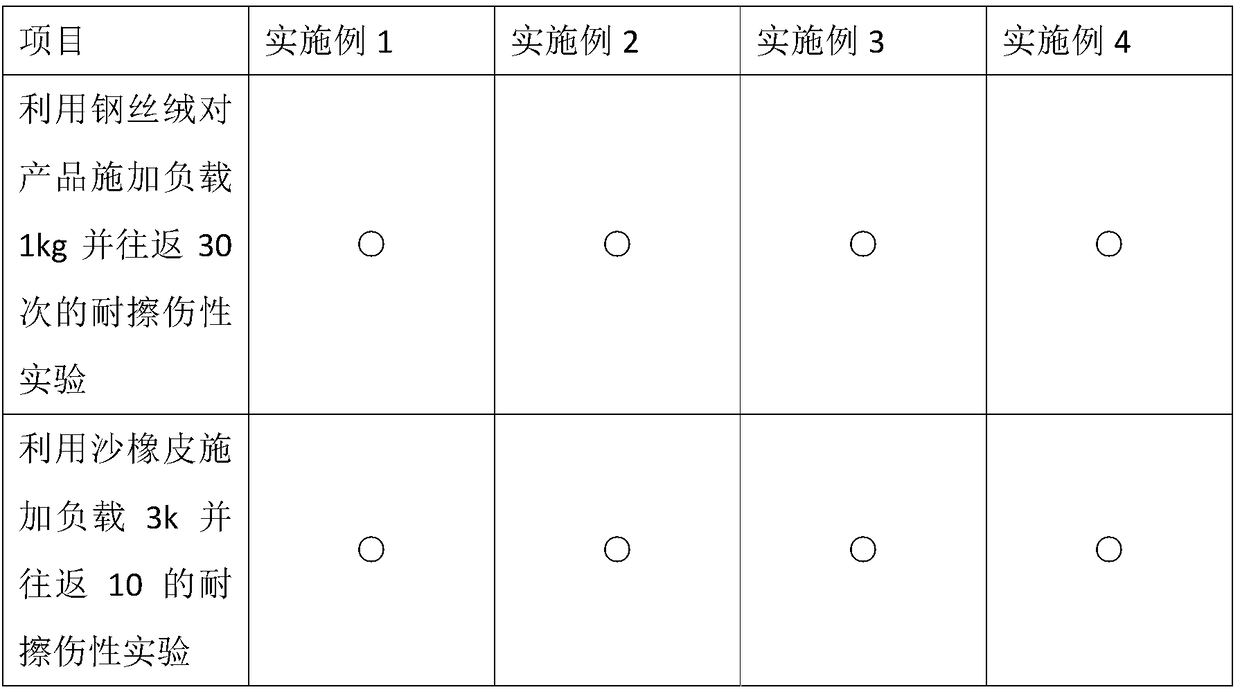

Examples

Embodiment 1

[0025] A kind of wear-resistant resin lens, comprises PMMA base sheet, and the wear-resisting layer that is directly or indirectly bonded on PMMA base sheet both sides; The raw material that prepares described PMMA base sheet comprises by its weight: 100 parts of PMMA resin, polycarbonate 10 parts, 10 parts of polystyrene resin, 3 parts of polypropylene glycol, 0.5 parts of 2'2'-azobis(2,4-dimethylvaleronitrile), 0.5 parts of sodium coconut oil acyl lactylate, 1 part of benzotriazole ; The wear-resistant layer is nano TiO 2 .

[0026] The preparation method of the above wear-resistant resin lens is characterized in that it comprises the following steps:

[0027] (1) Preparation of PMMA substrates: take the raw materials for preparing PMMA substrates in said parts by weight, add them to a mixing kettle, control the heating temperature to 120°C, heat and stir for 30min, and put them into a twin-screw extruder after cooling to room temperature Medium extrusion, the processing t...

Embodiment 2

[0030] A kind of wear-resistant resin lens, comprises PMMA base sheet, and the wear-resisting layer that is directly or indirectly bonded on PMMA base sheet both sides; The raw material that prepares described PMMA base sheet comprises by its weight: 100 parts of PMMA resin, polycarbonate 15 parts, 12 parts of polystyrene resin, 5 parts of polypropylene glycol, 3 parts of 4,4'-azobis(4-cyanovaleric acid), 1 part of sodium cocoyl lactylate, 2-hydroxy-4-n-octyloxy 2 parts of base benzophenone; the wear layer is nano-Al 2 o 3 and Nano Y 2 o 3 double-layer structure.

[0031] The preparation method of the above-mentioned wear-resistant resin lens comprises the following steps:

[0032] (1) Preparation of PMMA substrates: take the raw materials for preparing PMMA substrates in said parts by weight, add them to the mixing kettle, control the heating temperature to 150°C, heat and stir for 35min, and put them into a twin-screw extruder after cooling to room temperature Middle ex...

Embodiment 3

[0035] A kind of wear-resistant resin lens, comprises PMMA base sheet, and the wear-resisting layer that is directly or indirectly bonded on PMMA base sheet both sides; The raw material that prepares described PMMA base sheet comprises by its weight: 100 parts of PMMA resin, polycarbonate 20 parts, 15 parts of polystyrene resin, 8 parts of polypropylene glycol, 5 parts of benzoyl peroxide, 1.5 parts of sodium coconut oil acyl lactylate, 3 parts of 2-hydroxy-4-n-octyloxybenzophenone; wear-resistant layer Nano HfO 2 .

[0036] The preparation method of the above wear-resistant resin lens is characterized in that it comprises the following steps:

[0037] (1) Preparation of PMMA substrates: Take the raw materials for preparing PMMA substrates in said parts by weight, add them into a mixing kettle, heat and stir at 180°C, heat and stir for 40min, and put them into a twin-screw extruder after cooling to room temperature Extrusion, the processing temperature of the twin-screw extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com