Environment-friendly lubricating oil and preparation method thereof

A lubricating oil, environment-friendly technology, applied in the field of lubricating oil, can solve the problems of limited anti-oxidation stability, etc., and achieve excellent heat resistance stability, good rust resistance, and high anti-wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

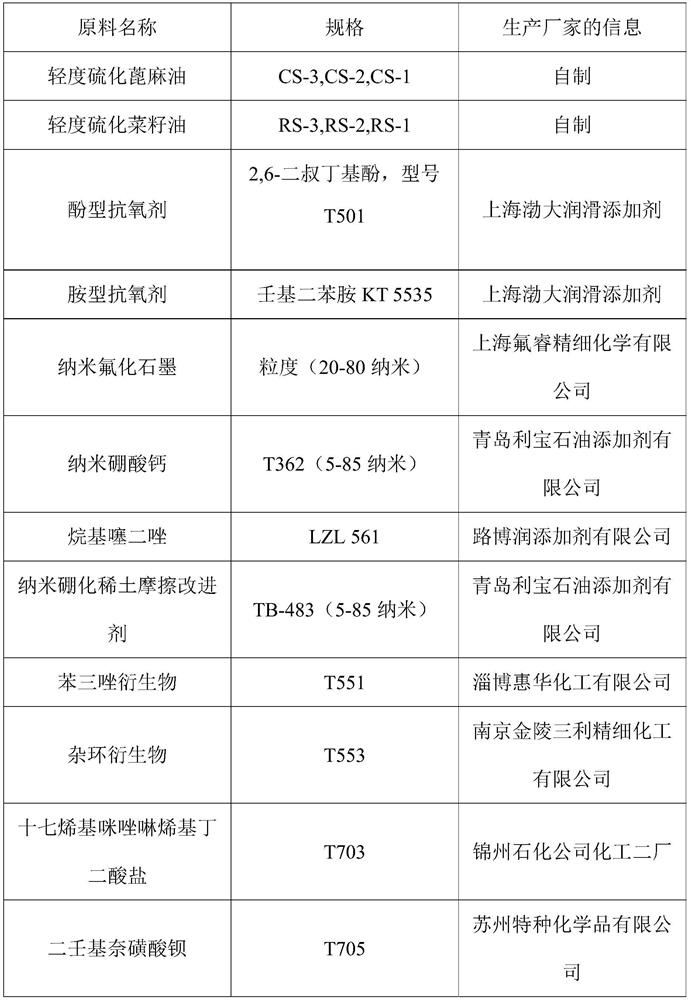

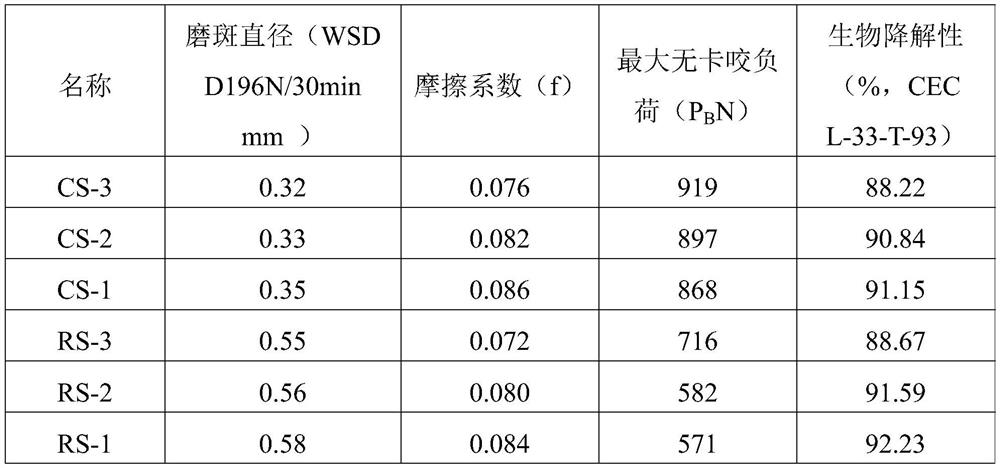

Method used

Image

Examples

Embodiment 1

[0035] An environment-friendly lubricating oil, comprising the following components in parts by weight: 41.3 parts of lightly sulfurized castor oil containing 2% sulfur, 41.3 parts of lightly sulfurized rapeseed oil containing 2% sulfur, 4.5 parts of phenolic high-efficiency antioxidant, Extreme pressure antiwear agent sulfurized isobutylene (T321) 4.2 parts, nanometer fluorinated graphite 2.2 parts, silicon ether polymer (T911) 0.8 parts, alkyl thiadiazole 1.7 parts, heptadecenyl imidazoenyl succinate 2.1 parts, zinc diamylcarbamate 1.9 parts

[0036] Its preparation method is as follows:

[0037] Put 41.3 parts of lightly sulfurized castor oil containing 2% sulfur and 41.3 parts of lightly sulfurized rapeseed oil containing 2% sulfur into the blending kettle, and put in the phenolic high-efficiency antioxidant in sequence under stirring at 60-63°C 4.5 parts, extreme pressure anti-wear agent vulcanized isobutylene T3214.2 parts, alkyl thiadiazole 1.7 parts, heptadecenyl imid...

Embodiment 2

[0039] An environment-friendly lubricating oil, comprising the following components in parts by weight: 40.2 parts of lightly sulfurized castor oil containing 3% sulfur, 50 parts of lightly sulfurized rapeseed oil containing 1% sulfur, 1.3 parts of amine-type high-efficiency antioxidant, 2.4 parts of tricresyl phosphate, 0.5 parts of nano calcium borate, 0.3 parts of silicon ether polymer (T911), 2.0 parts of benzotriazole derivatives, 1.2 parts of barium dinonyl naphthalenesulfonate, 2.1 parts of zinc diamylcarbamate .

[0040]Put 40.2 parts of environmentally friendly base oils of mildly vulcanized castor oil containing 3% sulfur and 50 parts of lightly vulcanized rapeseed oil containing 1.3 parts of antioxidant, 2.4 parts of tricresyl phosphate, extreme pressure antiwear agent, 2.0 parts of benzotriazole derivatives, 1.2 parts of barium dinonyl naphthalene sulfonate, 2.1 parts of zinc diamyl carbamate, and then put in nanometer calcium borate 0.5 parts, 0.3 parts of silico...

Embodiment 3

[0042] An environment-friendly lubricating oil, comprising the following components in parts by weight: 32 parts of lightly sulfurized castor oil containing 1% sulfur, 42.2 parts of lightly sulfurized rapeseed oil containing 1% sulfur, 2 parts of phenolic antioxidant, amine 3.6 parts of high-efficiency antioxidant, 2.4 parts of tricresyl phosphate, 2.9 parts of sulfurized isobutylene, 2.8 parts of nano-boride rare earth friction modifier, 1.8 parts of ether polymer (T903), 3.8 parts of heterocyclic derivatives, N-oil Acyl sarcosine-stearyl ammonium salt 2.2 parts, dialkyl dithiophosphate zinc 4.3 parts.

[0043] Put 32 parts of environmentally friendly base oils of lightly sulfurized castor oil containing 1% sulfur, and 42.2 parts of lightly sulfurized rapeseed oil containing 2 parts of oxygen agent, 3.6 parts of amine type high-efficiency antioxidant, 2.4 parts of tricresyl phosphate, 2.9 parts of sulfurized isobutylene, 3.8 parts of heterocyclic derivatives, 2.2 parts of N-o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com