Preparation method of graphene lubricating oil, graphene lubricating oil and application

A lubricating oil and graphene technology, applied in the field of lubricating oil, can solve problems such as aggravating environmental pollution and the impact of lubricating oil, and achieve the effects of simple process, low production cost, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

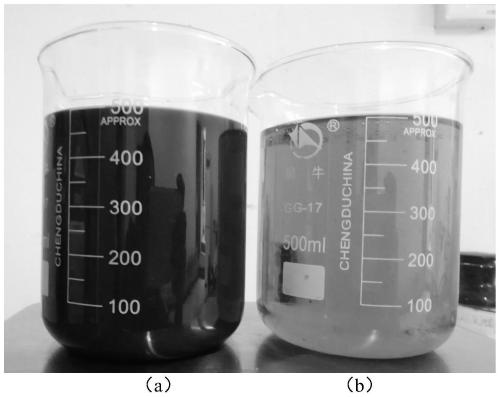

[0056] According to a first aspect of the present invention, a kind of preparation method of graphene lubricating oil is provided, comprising the following steps:

[0057] Provide a dispersion of graphite and lubricating base oil;

[0058] The dispersion liquid is processed by ultra-high pressure micro-jet technology, and the processing pressure is 180-380 MPa to obtain graphene lubricating oil.

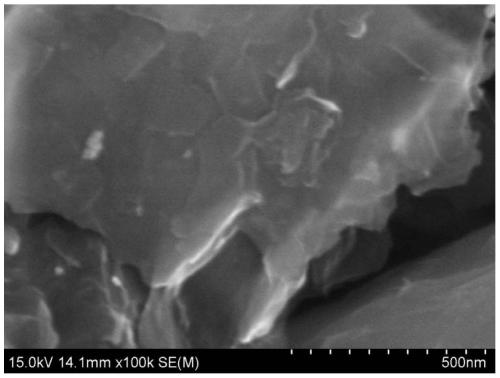

[0059] Specifically, graphite is an allotrope of carbon, gray-black, and using graphite as a raw material for preparing graphene can effectively reduce the production cost of graphene.

[0060] The ultra-high pressure micro-jet method combines the high-pressure jet method, the impinging flow method and the traditional high-pressure homogenization method. It uses high pressure to transport the material to the micro-fluidizer and gives the material a high flow rate. The material at a very high flow rate is in the micropore. The shearing effect occurs in the channel and disperses into ...

Embodiment approach

[0086] As an optional embodiment of the present invention, the metal oxide includes any one or a combination of at least two of manganese oxide, magnesium oxide, calcium oxide, copper oxide, iron oxide, aluminum oxide, zinc oxide or titanium dioxide.

[0087] Preferably, the metal sulfide includes any one or a combination of at least two of molybdenum disulfide, sodium sulfide, zinc sulfide or silver sulfide.

[0088] Preferably, the silicon material includes silicon and / or silicon oxide.

[0089] Preferably, the carbon material includes carbon black and / or fullerenes.

[0090] As an optional embodiment of the present invention, the mass fraction of the antiwear agent in the dispersion is 0.01-1%. Typical but non-limiting mass fractions of the antiwear agent in the dispersion are 0.01%, 0.02%, 0.03%, 0.04%, 0.05%, 0.06%, 0.08%, 0.10%, 0.10%, 0.2%, 0.3%, 0.4% %, 0.5%, 0.6%, 0.8%, 0.9% or 1%.

[0091] By limiting the specific type and amount of the anti-wear agent, the obtained...

Embodiment 1

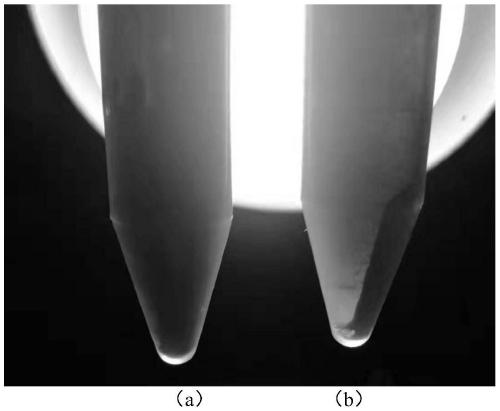

[0114] The present embodiment provides a kind of preparation method of graphene lubricating oil, comprises the following steps:

[0115] (a) Graphite powder and 4L lubricating base oil are placed in reaction kettle, stir 30min, obtain dispersion liquid, wherein the average particle diameter of graphite powder is 10 μ m, and its mass fraction in dispersion liquid is 0.1%;

[0116] (b) Process the dispersion twice with an ultra-high pressure micro-fluidic device at a pressure of 200 MPa to obtain a graphene lubricating oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com