Surface-hardening treatment method of sealing pairs and friction pairs of titanium and titanium alloy ball valves

A hardening treatment and titanium alloy technology, which is applied in gaseous chemical plating, superimposed layer plating, metal material coating technology, etc., can solve the problem of not being able to meet the wear resistance and long-term sealing requirements of titanium and titanium alloy ball valves, which cannot be realized Long-term wear resistance requirements, limited wear resistance of coatings and other issues, to achieve the effects of easy local protection, environmental protection, and improved hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

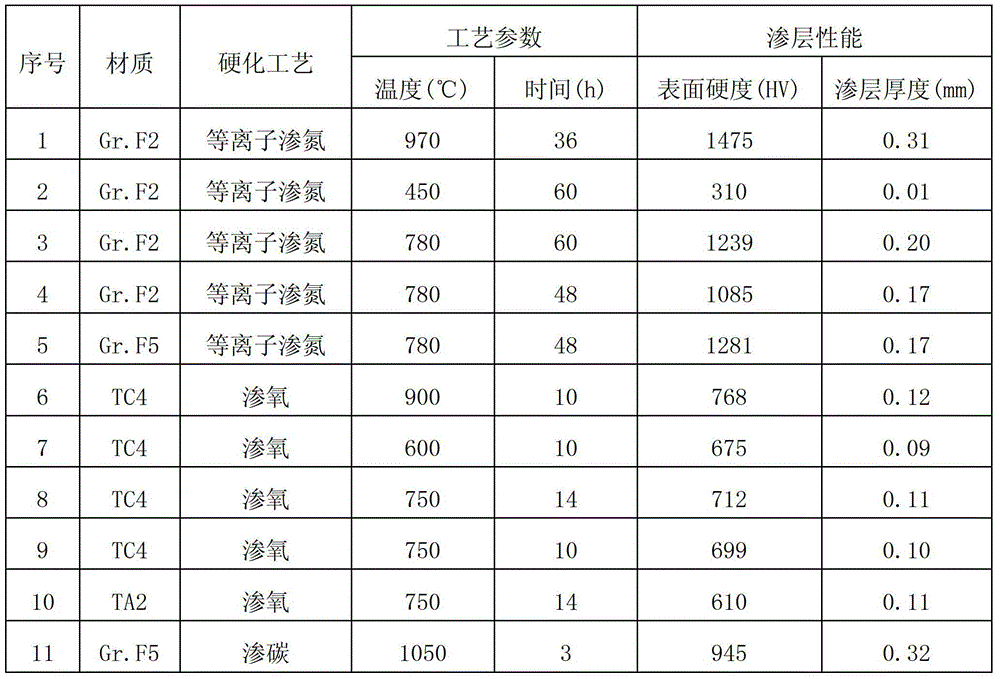

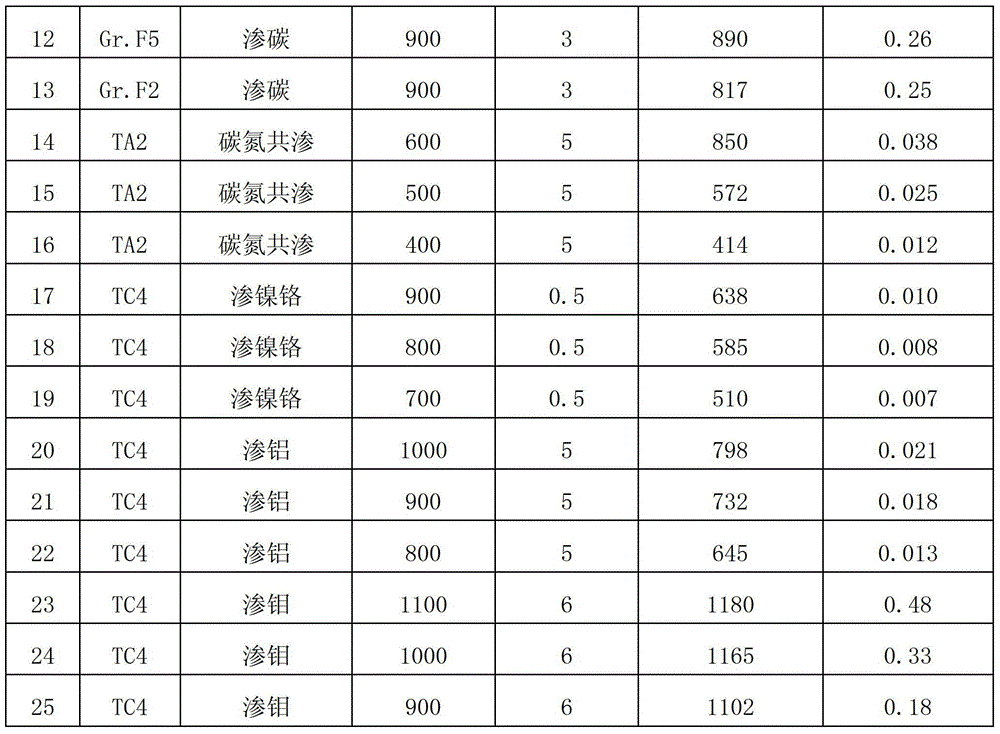

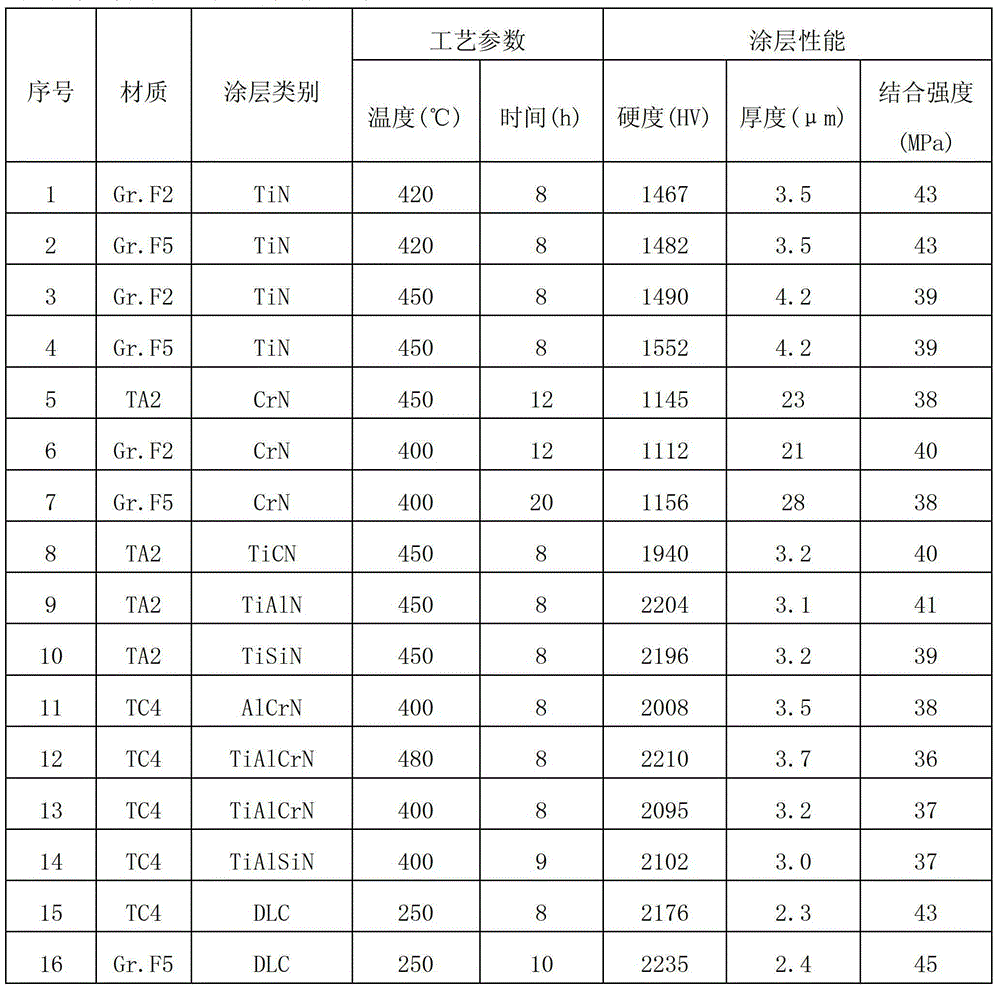

[0034] The invention relates to a surface hardening treatment method for the sealing pair and friction pair of titanium and titanium alloy ball valves. The surface hardening treatment method involves chemical heat treatment and vapor deposition hard coating, and chemical heat treatment + vapor deposition hard coating is applied to titanium simultaneously. And the sealing pair and friction pair of titanium alloy ball valves solve the problem of low surface hardness of titanium and titanium alloy ball valves after single chemical heat treatment. On the basis of chemical heat treatment, vapor deposition hard coating is used to reduce the penetration layer of chemical heat treatment. The problem of poor hardness, the vapor deposition hard coating further improves the bonding strength of the chemical heat treatment infiltrated layer, and improves the hardness of the surface of titanium and titanium alloy ball valves. Even if the vapor deposition hard coating is damaged during actual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com