Surface-controllable composite strengthening method for forged steel crankshaft material

A technology for crankshafts and forging steels is applied in the field of surface controllable composite strengthening of forged steel crankshaft materials, which can solve the problems of limited improvement in surface hardness and fatigue performance, and achieve the effects of low cost, production cost saving, and hardness reduction requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

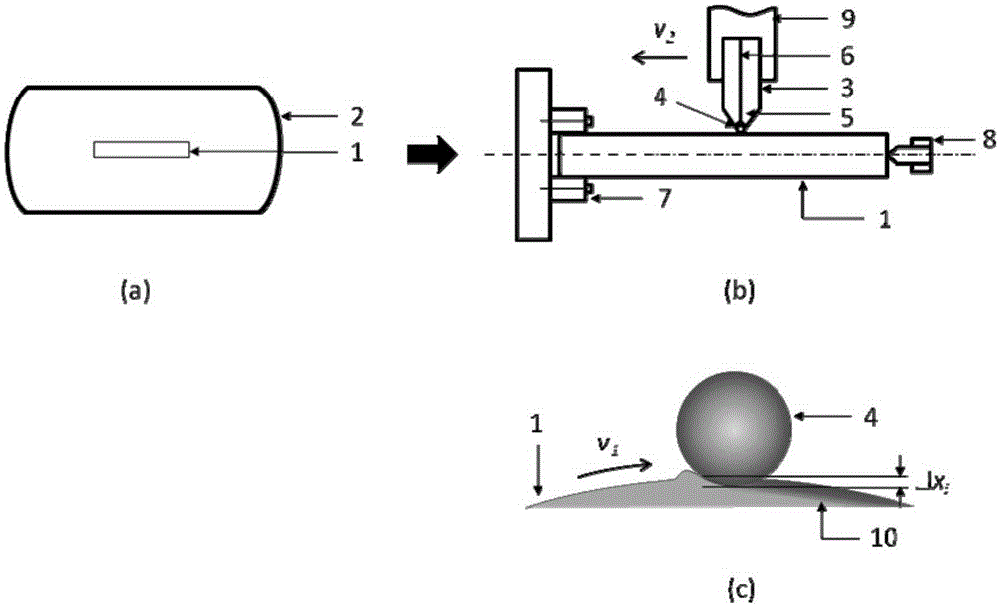

Method used

Image

Examples

Embodiment 1

[0044] The chemical composition of 42CrMoA alloy steel for forged steel crankshaft is (wt.%): C0.41%, Si0.23%, Mn0.75%, S0.024%, P0.015%, Cr1.12%, Mo0.22 %, Cu0.02%, the balance of Fe. The supply state of 42CrMoA alloy steel is forged, and the diameter of the test rod is 20mm (the size used for surface mechanical rolling and nano-processing).

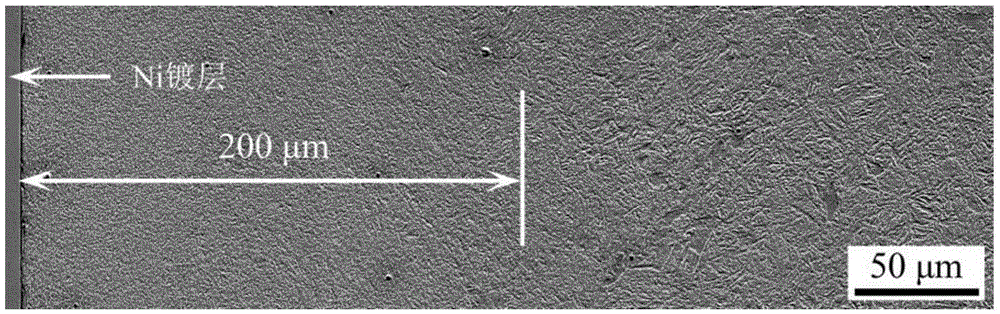

[0045] Using the surface controllable composite strengthening method of the present invention to treat the forged steel crankshaft with 42CrMoA alloy steel, the specific process is as follows: (1) heat treat the 42CrMoA alloy steel by adopting a heat treatment process (quenching and tempering treatment). Firstly, the 42CrMoA alloy steel is subjected to normalizing pretreatment, the normalizing temperature is 900°C, the holding time is 300min, and the cooling method is air cooling. Then the 42CrMoA alloy steel is quenched and quenched by a resistance heating furnace. The quenching temperature of the resistance heating furnace is 850°C,...

Embodiment 2

[0048] The chemical composition, supply state and size of the test rod of the 42CrMoA alloy steel for the forged steel crankshaft selected in this embodiment are all the same as those in Embodiment 1.

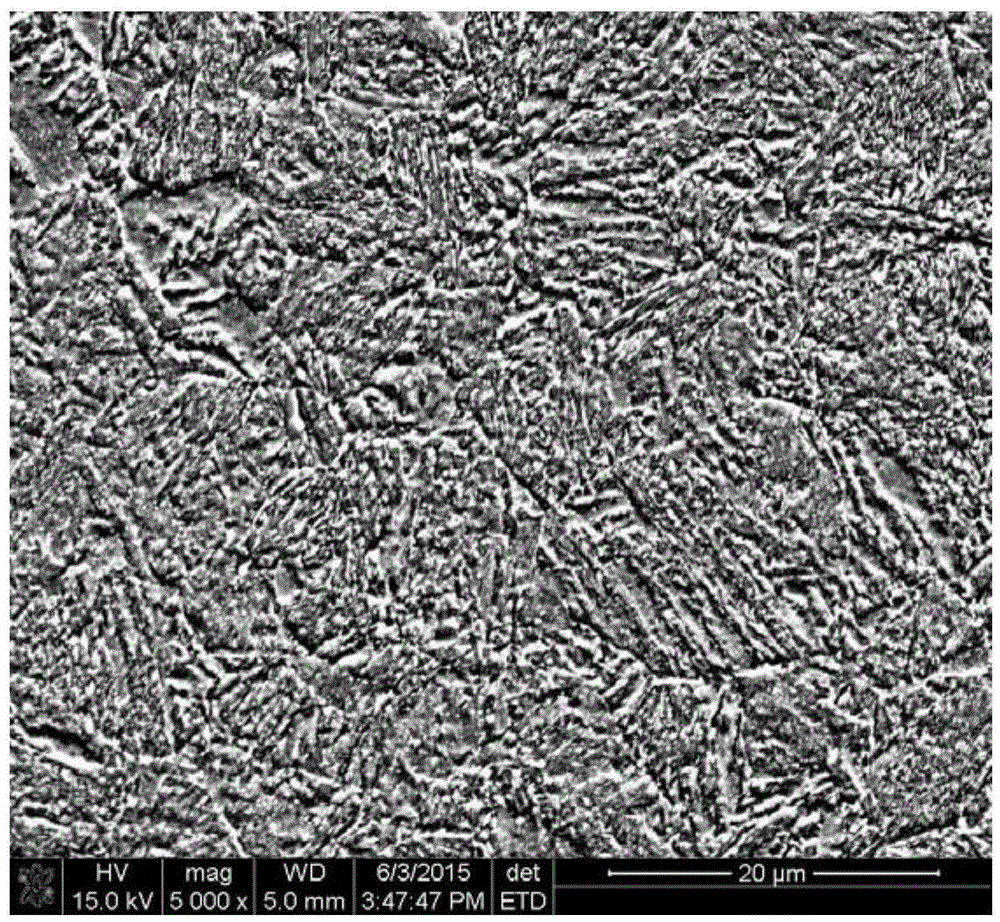

[0049] The forged steel crankshaft is treated with 42CrMoA by using the surface controllable composite strengthening method of the present invention, and the specific process is as follows: (1) The 42CrMoA alloy steel is heat treated by a heat treatment process (intermediate frequency quenching + low temperature tempering process). The intermediate frequency induction hardening is carried out in the intermediate frequency induction hardening furnace, the quenching temperature is 860°C; the low temperature tempering is carried out in the resistance heating furnace, the tempering temperature is 240°C, the holding time is 120min, and air cooling after heat preservation, the finally obtained 42CrMoA alloy steel surface layer In the larger depth range (≥3mm), there is acicular marten...

Embodiment 3

[0052] The chemical composition, supply state and size of the test rod of the 42CrMoA alloy steel for the forged steel crankshaft selected in this embodiment are all the same as those in Embodiment 1.

[0053] The forged steel crankshaft is treated with 42CrMoA by using the surface controllable composite strengthening method of the present invention, and the specific process is as follows: (1) The 42CrMoA alloy steel is heat treated by a heat treatment process (intermediate frequency quenching + low temperature tempering process). The medium frequency induction hardening is carried out in the medium frequency induction hardening furnace, the quenching temperature is 860°C; the low temperature tempering is carried out in the resistance heating furnace, the tempering temperature is 210°C, the holding time is 120min, and air cooling after heat preservation, the final 42CrMoA alloy steel surface layer is obtained In the larger depth range (≥3mm), there is acicular martensitic struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com