Double carburization protecting process in manufacture of bearing outer ring of squirrel-cage elasticity support

A technology of bearing outer ring and squirrel cage spring support, applied in the field of bearing processing, can solve the problems of difficult to meet the technical requirements of parts, difficult to guarantee the thickness of copper plating layer, and can not meet the technical requirements of parts, etc., to achieve high utilization rate of materials, The effect of shortening machining time, machining cost and tool cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

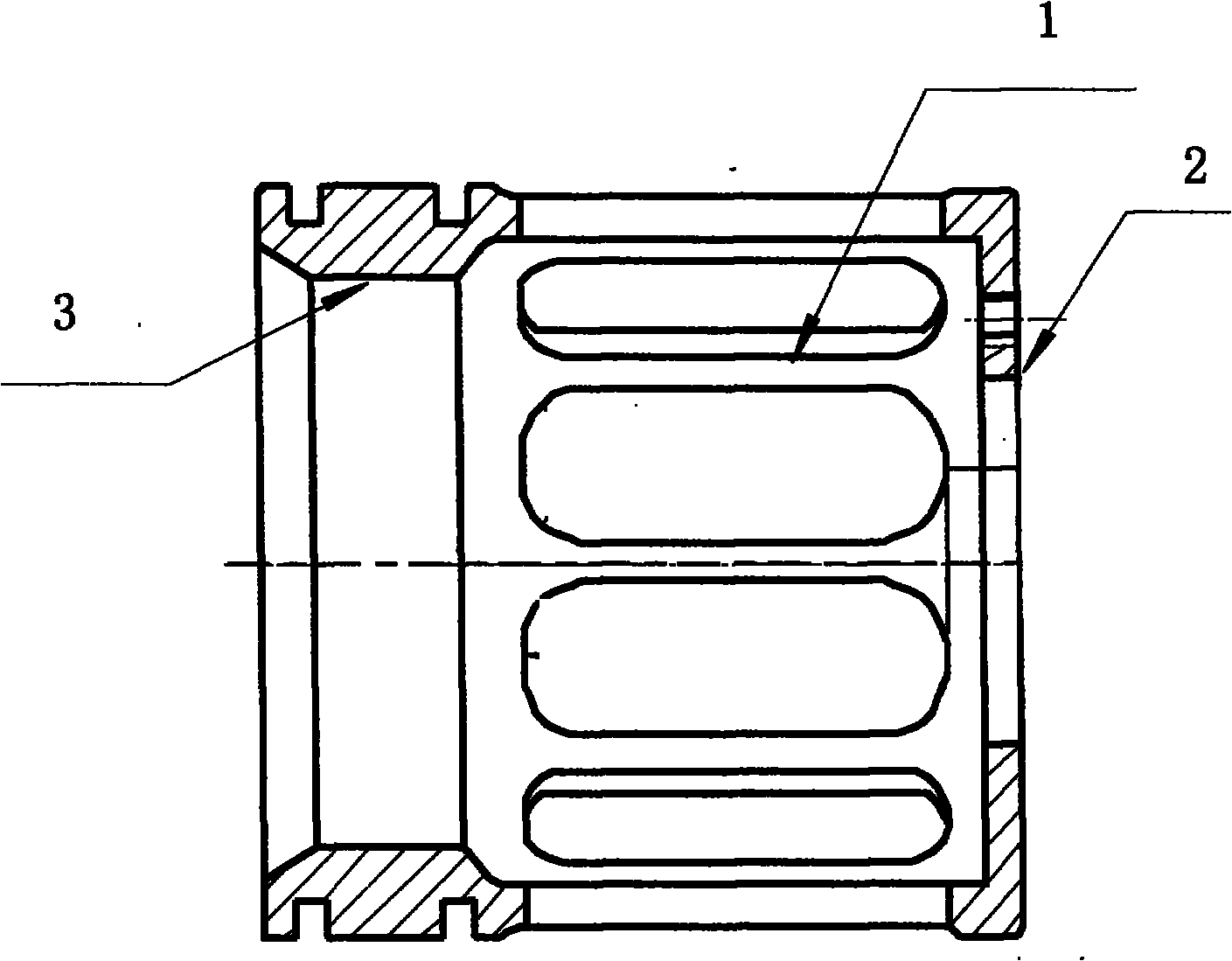

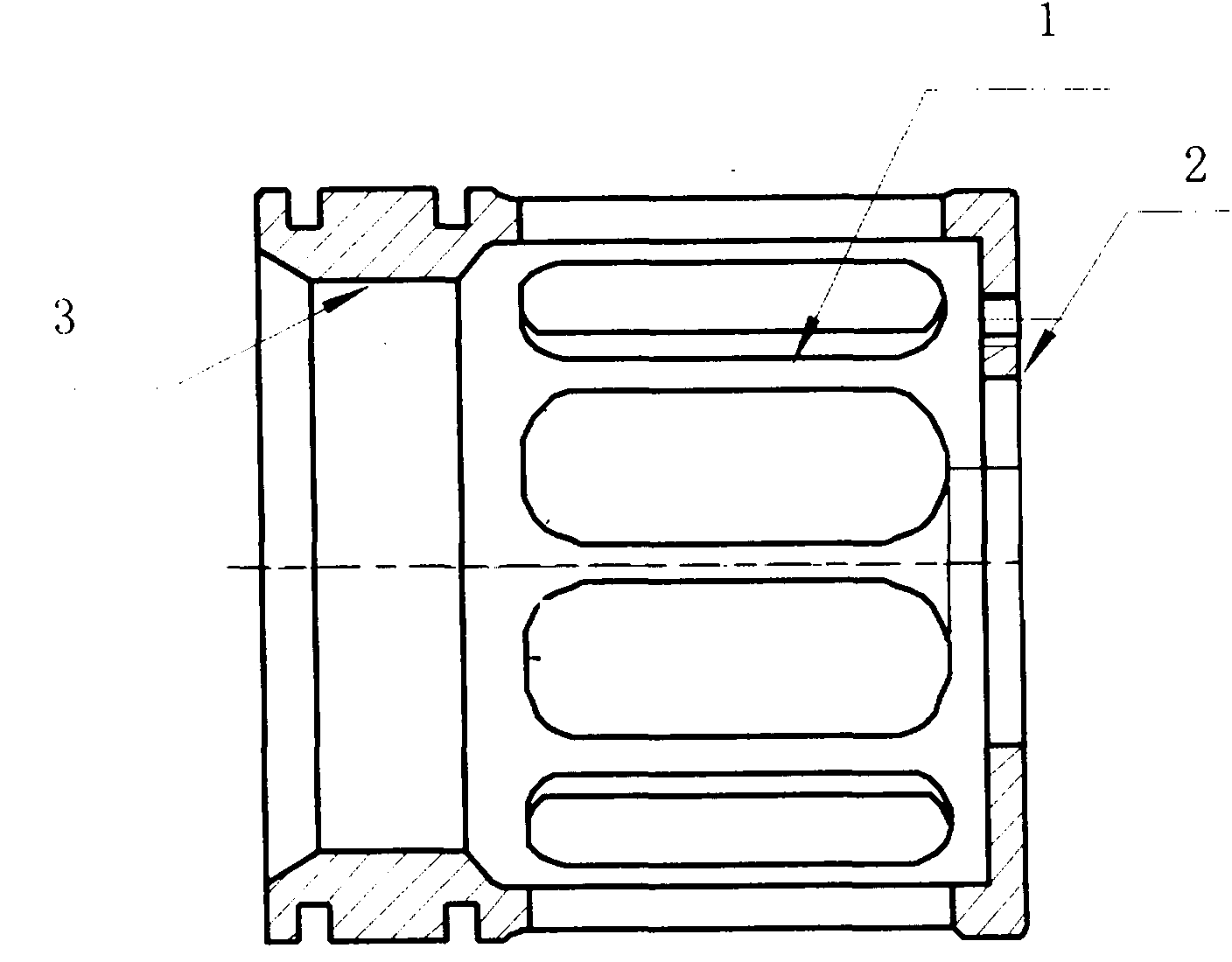

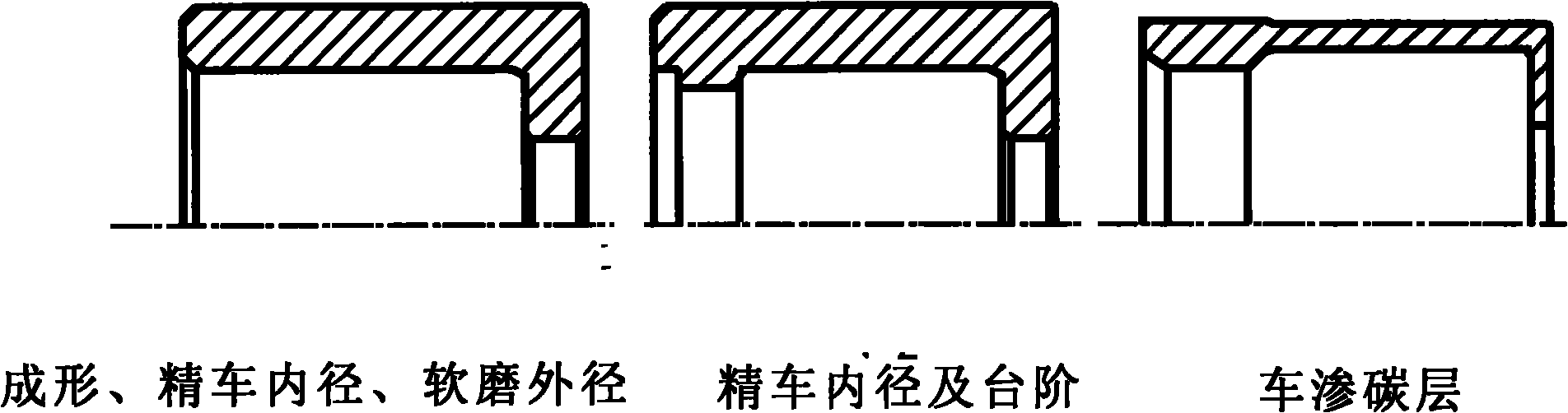

[0032] As shown in Figure 1: The processing technology of the outer ring of the squirrel cage spring bearing is to ensure the smooth progress of the lathing process after quenching, and adopts double carburizing protection measures of copper plating and additional amount; when lathe processing, first consider non-rolling The amount reserved on the surface of the raceway is 2mm±0.05. After the carburizing process, the decarburized layer has reached the size required by the finished car. The raceway is finished before the carbon process to ensure the full infiltration of carbon elements on the raceway surface. The main technological process of the outer ring processing technology of squirrel cage elastic bearing is as follows:

[0033] 1. After the turning forming process, in order to ensure the accuracy of the product, arrange the soft grinding outer diameter and fine turning inner diameter process → finish turning the outer inner diameter and inner diameter steps on the CNC la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com