A through-beam type high temperature resistant smoke sensor and real-time detection method

A high temperature, sensor technology, applied in the direction of color/spectral characteristic measurement, etc., can solve the problem of smoke sensor not working normally, unable to work, smoke detection sensitivity is reduced, etc., to achieve strong real-time, strong anti-interference, low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for real-time detection of through-beam high-temperature-resistant smoke and dust, comprising the following steps:

[0029] The light emitted by the laser light source passes through an optical narrow-band filter to output light of a specific wavelength, and the receiving end is equipped with the same optical narrow-band filter as the transmitting end, which can effectively eliminate the interference caused by the ambient light to the detection system;

[0030] At the transmitting end, the laser first passes through an optical narrow-band filter and then an optical isolator, and then passes through a pure silica fiber with a core diameter of 800 μm and stainless steel armor to connect to the laser probe.

[0031] The input end of the optical isolator is connected to the output end of the optical narrowband filter, so that the laser light source is not affected by the back reflection and scattered light of the optical path in the system, and can work stably when ...

Embodiment 2

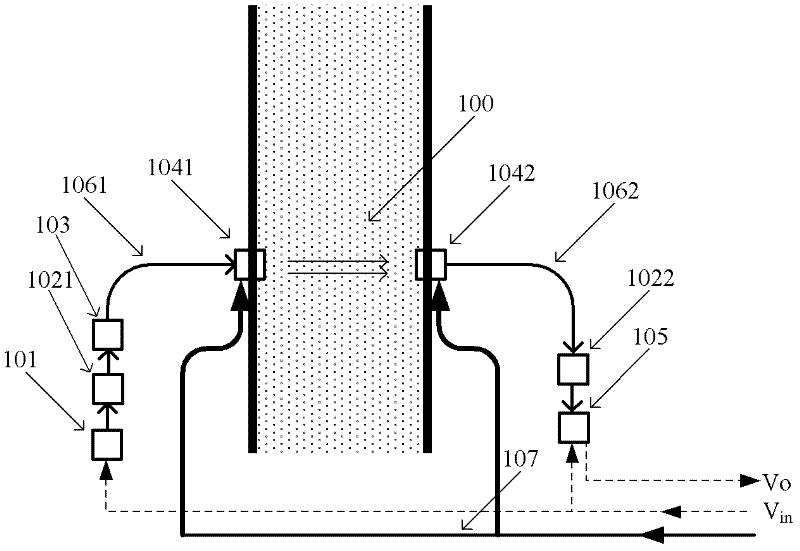

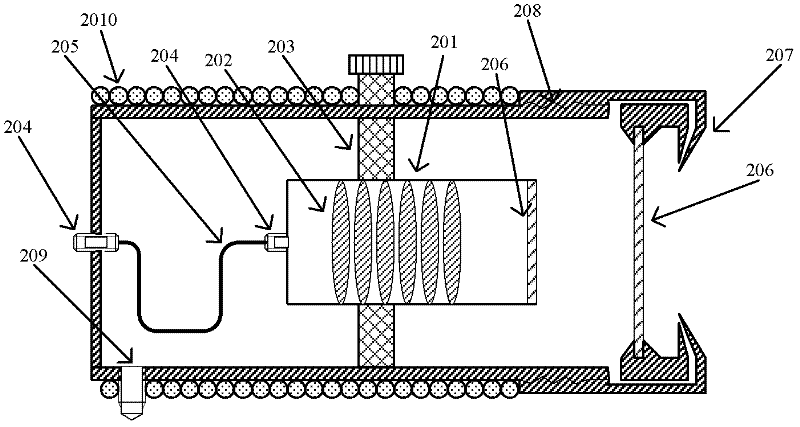

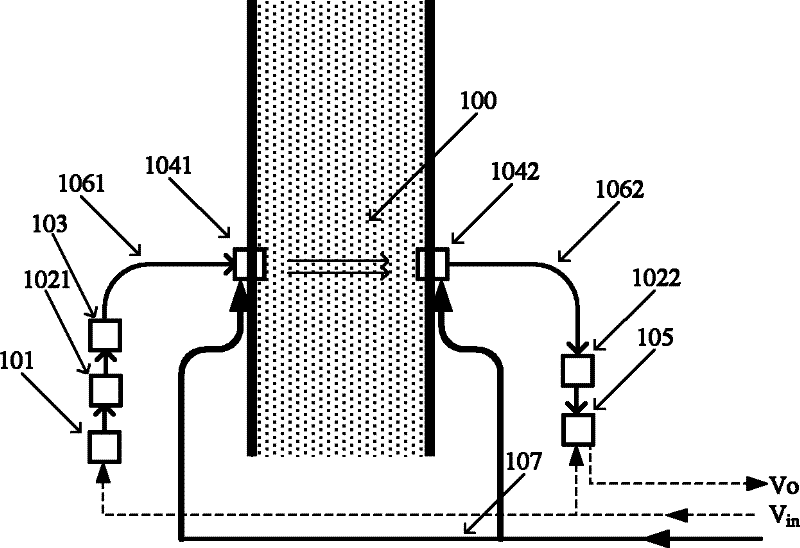

[0044] A through-beam type high temperature resistant smoke sensor provided by the present invention, such as figure 1 , figure 2 shown. Including: a laser light source 101, a first optical narrowband filter 1021, a second optical narrowband filter 1022, an optical isolator 103, a first laser probe 1041, a second laser probe 1042, a photodetector 105, and a first core diameter of 800 μm Armored pure silica fiber 1061, armored pure silica fiber 1062 with a second core diameter of 800 μm, gas supply pipe 107, dust medium 100, laser beam expanding collimating lens 201, laser beam expanding collimating lens group 202, 5-dimensional adjustment Frame 203, flange 204, pure silica optical fiber 205 with a core diameter of 800 μm, pure quartz lens 206, gas nozzle 207, spiral thread port 208, gas input port 209, and pure copper aqueduct 2010.

[0045] The first laser probe 1041 and the second laser probe 1042 consist of a laser beam expansion collimator lens 201, a 5-dimensional adju...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com