Bacillus subtilis H8-3 and application thereof

A technology of Bacillus subtilis and decomposing bacteria agent, applied in the direction of application, bacteria, biochemical equipment and methods, etc., can solve the problems of low compost fermentation efficiency, achieve the effect of high protease activity and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

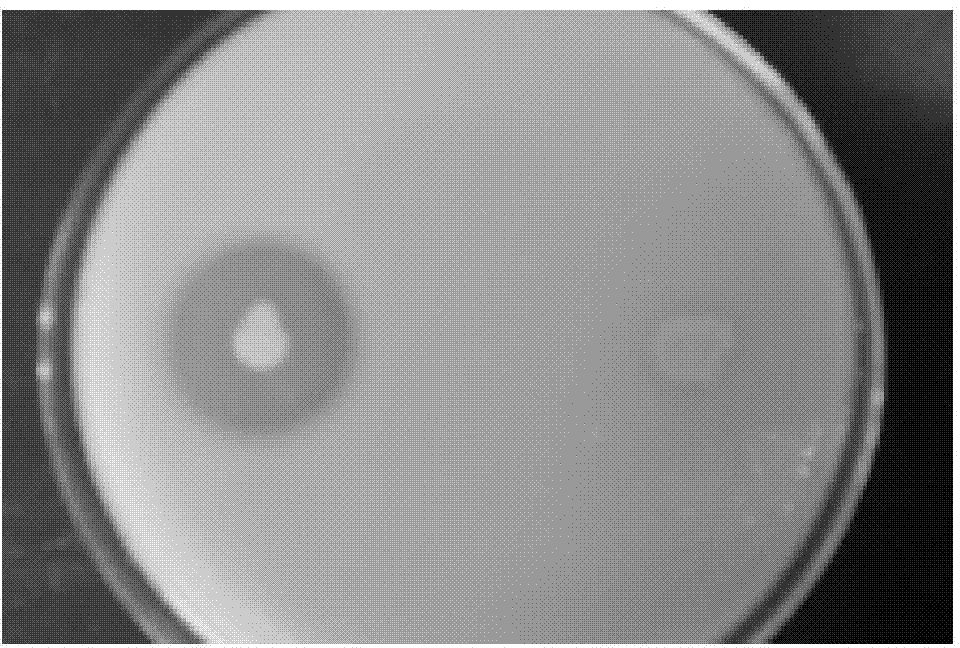

[0055] Example 1 strain screening and identification

[0056] 1. Screening and identification of strain H4

[0057] (1) Culture medium and reagent formula:

[0058] The final concentration of SOC liquid medium is composed of: tryptone 20g / L, yeast extract 5g / L, NaCl 0.5g / L, KCl 2.5mmol / L, MgCl 2 0.01mol / L, glucose 0.02mol / L, solvent is deionized water, pH value 7.0.

[0059] The final concentration of the SOC solid medium is composed of: SOC liquid medium plus agar powder with a final mass concentration of 1.5%.

[0060] Preparation method of SOC liquid medium: For each liter of medium, add 20g of tryptone, 5g of yeast extract, and 0.5g of NaCl into 965ml of deionized water and shake the container to completely dissolve the solute. Add 10ml 250mmol / L KCl aqueous solution, use 5mol / L NaOH to adjust the pH to 7.0, at 15psi (1.05kg / cm 2 ) steam sterilization under high pressure for 20min. Add 5ml filter-sterilized 2mol / L MgCl to the sterilized solution 2 , cooled to 60°C or...

Embodiment 2

[0133] Embodiment 2 decomposing bacteria agent

[0134] (1) Bacillus subtilis H4 freeze-dried powder

[0135] a. Incline cultivation

[0136] Bacillus subtilis H4 was inoculated into slant LB medium and cultured at 37°C for 1 day to obtain slant cells.

[0137] b. Seed cultivation

[0138] Pick an inoculation loop strain from the slant bacteria, inoculate it into 100ml LB liquid medium, culture it on a shaker at 50°C for 24 hours, and obtain a seed solution.

[0139] c. Fermentation culture

[0140] The seed solution was inoculated into the fermentation medium at a volume ratio of 1:1000, and fermented at 50°C for 24 hours. The pressure of the fermenter was 0.04MPa, the ventilation rate was 0.2v / v.min, and the rotation speed was 200rpm. The fermented liquid was taken and centrifuged, the wet cells were collected, and freeze-dried at -50°C for 24 hours to obtain the freeze-dried powder of Bacillus subtilis H4.

[0141] The final concentration of the fermentation medium is ...

Embodiment 3

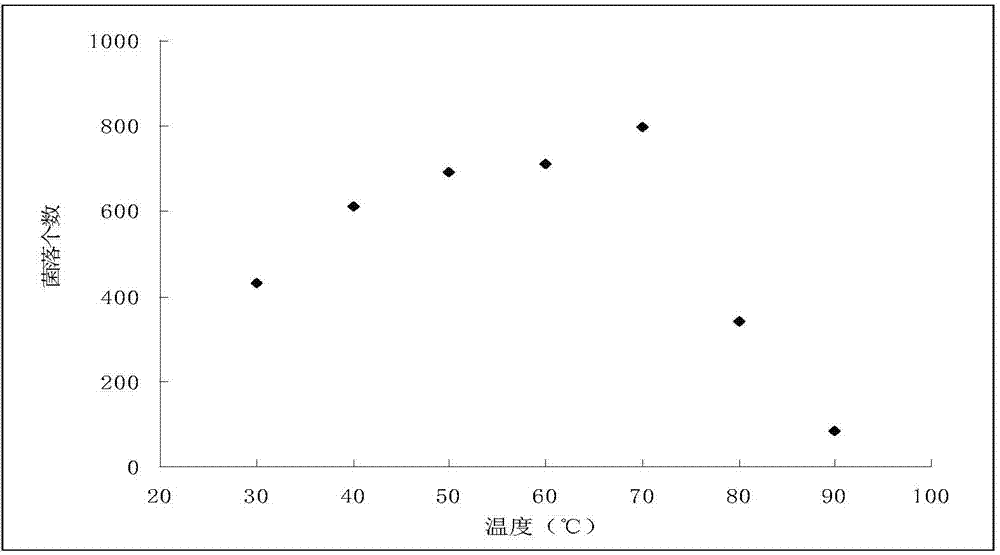

[0150] The character of embodiment 3 decomposing bacterial agents

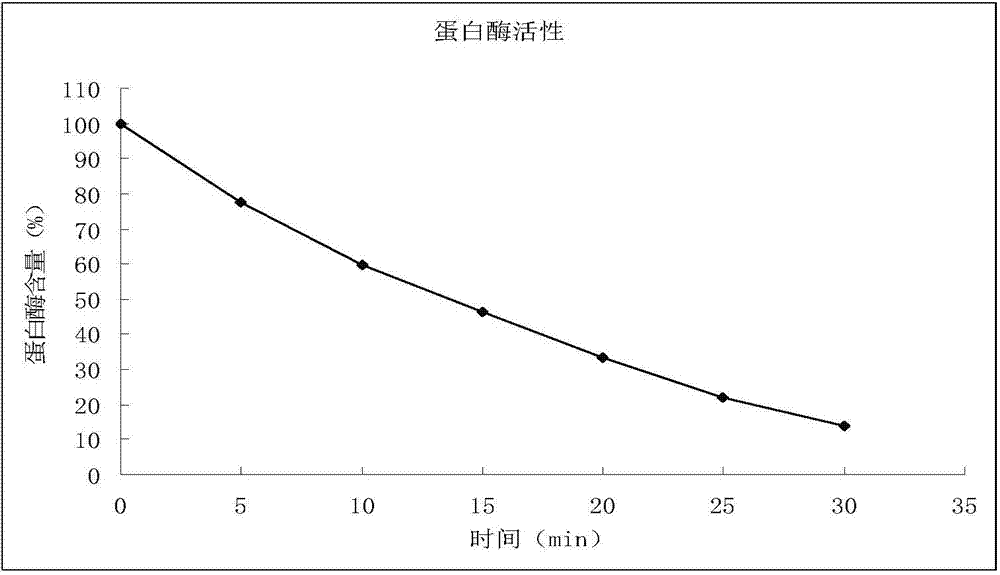

[0151] (1) Protease activity

[0152] Prepare L-tyrosine standard solutions of 10, 20, 30, 40, 50, and 60 μg / ml, use double-distilled water without tyrosine as a blank control, and measure the absorbance at a wavelength of 275 nm with an ultraviolet spectrophotometer. Taking the absorbance as the ordinate and the concentration of tyrosine as the abscissa, a standard curve was drawn to obtain the equation y=0.0074x, and the absorption constant K was 135.1.

[0153] Take 10 g of the decomposed microbial agent prepared by the method in Example 2, add 100 ml of 0.1 mol / L phosphate buffer solution (pH=7.5), and shake on a shaker at 200 rpm for 30 min. Centrifuge at 3000rpm and take the decomposing agent supernatant.

[0154] Take 1.0ml of decomposing agent supernatant, keep it warm at 40°C for 2 minutes, add 1.0ml casein aqueous solution (10mg / ml), mix well and react at 40°C for 20min, add 2ml trichloroacetic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com