Novel functional group-containing fluorine-modified silicone oils and preparation method thereof

A functional group and fluorine modification technology, applied in the field of silicone polymer materials, can solve the problems of limited application range expansion, methyl hydrogen-containing silicone oil resistance to fuel oil, poor resistance to chemical media, etc., to achieve unique surface activity and chemical stability , good comprehensive effect and simple process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

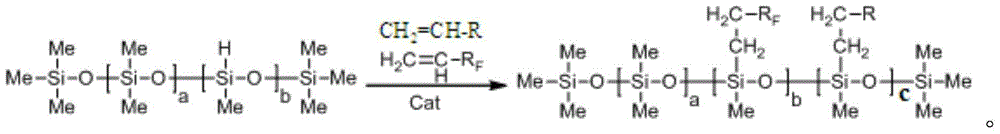

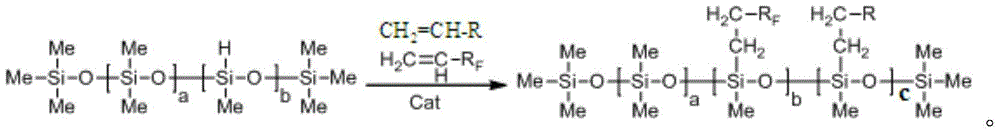

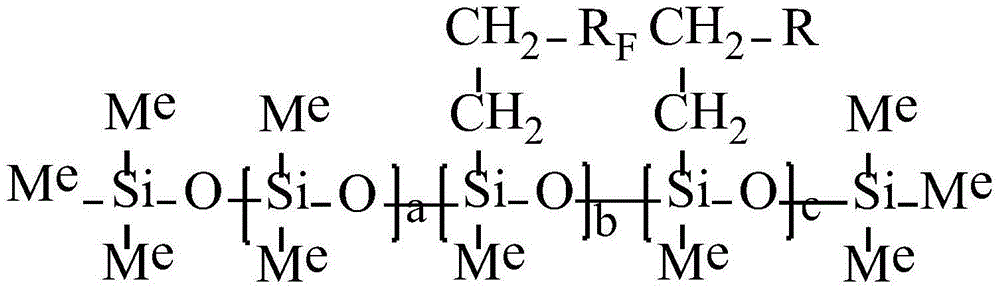

Method used

Image

Examples

Embodiment 1

[0020] Add 73.8g perfluorobutylethylene and 20ppm platinum catalyst into a four-necked flask equipped with a stirrer, reflux condenser, constant pressure dropping funnel and thermometer, and add 60g of hydrogen-containing silicone oil dropwise under nitrogen protection. Keep the temperature at 90°C for constant temperature reaction for 2 hours, then add 17.4g of allyl alcohol dropwise, after the dropwise addition, perform constant temperature reaction for 2 hours, and finally remove the remaining perfluorobutylethylene and allyl alcohol by distillation under reduced pressure to obtain 114.2 fluorine modified silicone oil containing hydroxyl g.

Embodiment 2

[0022] Add 69.2g perfluorohexylethylene and 20ppm platinum catalyst into a four-necked flask equipped with a stirrer, reflux condenser, constant pressure dropping funnel and thermometer, add 40g of hydrogen-containing silicone oil dropwise under nitrogen protection, and keep The temperature was 100°C for constant temperature reaction for 2 hours, and then 11.6 g of allyl alcohol was added dropwise. After the dropwise addition, it was reacted for 2 hours at constant temperature. Finally, the remaining perfluorohexylethylene and allyl alcohol were removed by vacuum distillation to obtain 92.3 g of hydroxyl-containing fluorine-modified silicone oil.

Embodiment 3

[0024] Add 89.2g of perfluorooctylethylene and 20ppm platinum catalyst in a four-necked flask equipped with a stirrer, reflux condenser, constant pressure dropping funnel and thermometer, and add 40g of hydrogen-containing silicone oil dropwise under nitrogen protection. Keep the temperature at 110°C for a constant temperature reaction for 2 hours, then add 28.4 g of glycidyl methacrylate dropwise, and react for 2 hours at a constant temperature after the dropwise addition, and finally remove the remaining perfluorooctylethylene and glycidyl methacrylate by distillation under reduced pressure to obtain 109.8g of ester group epoxy group fluorine modified silicone oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com