A kind of epoxy powder insulation anticorrosion coating

An anti-corrosion coating and electrical insulation technology, applied in powder coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve problems such as reduced coating adhesion, and achieve the effects of strong adhesion, low cost, and excellent electrical insulation performance.

Inactive Publication Date: 2011-12-28

NINGBO KEXIN CORROSION CONTROL ENG

View PDF5 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, a substantial increase in the filler content in the paint may lead to a decrease in paint adhesion

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0010] Both the primer coating and the surface coating of the present invention are made into powder products by melt extrusion mixing method, which meet the standard requirements of HG / T2006-2006 "Thermosetting Powder Coatings".

[0011] Its primer and surface coating formulation examples are as follows:

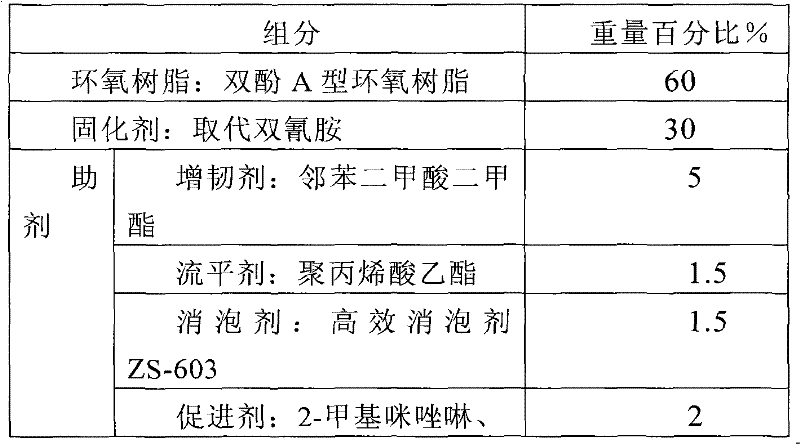

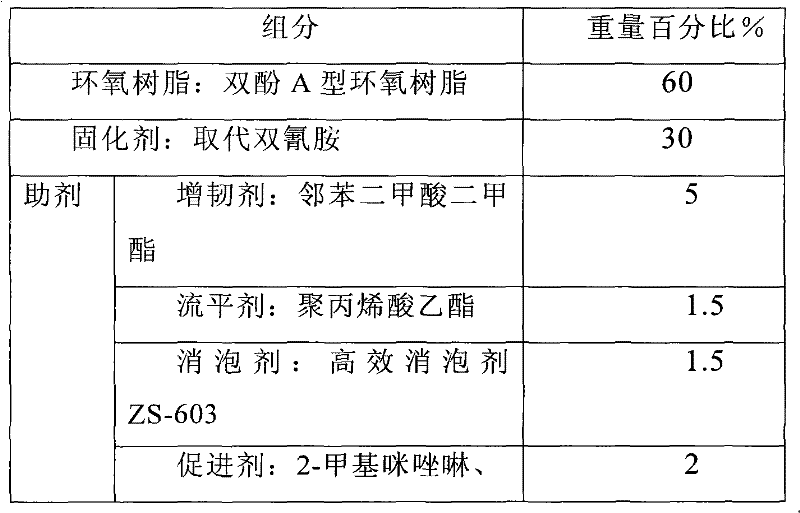

[0012] Primer Coating Formulation:

[0013]

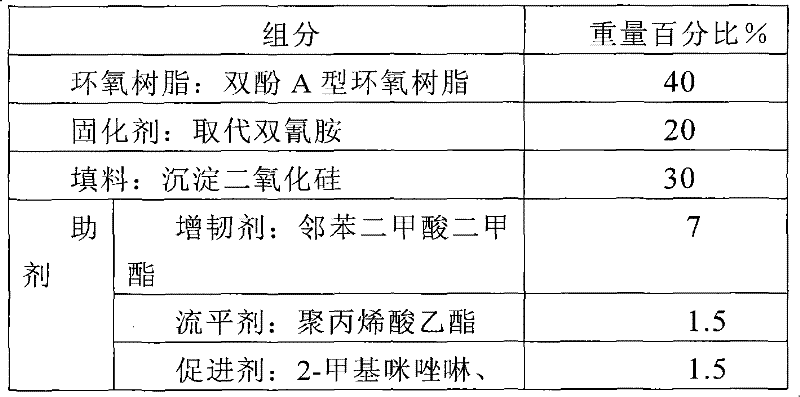

[0014] Topcoat formulation:

[0015]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to thermosetting epoxy powder insulation anticorrosion paint. It consists of a primer and a top coat, which together form an electrically insulating and anti-corrosion coating. The primer is composed of epoxy resin, curing agent and auxiliary agent; the surface coating is composed of epoxy resin, curing agent, filler and other auxiliary agents; both the primer and the surface coating are made by melt extrusion mixing method Powdered product. The primer coating does not contain or contains less filler, so the adhesion of the formed primer coating is not affected; the surface coating bears the main functions of electrical insulation and anti-corrosion, so the coating of the present invention has strong adhesion, excellent electrical insulation performance, and has Anti-corrosion, anti-rust, anti-mildew, heat-resistant, wear-resistant and other functions, and has the characteristics of low cost.

Description

technical field [0001] The invention belongs to the technical field of powder coatings, and in particular relates to thermosetting epoxy powder insulation anticorrosion coatings. technical background [0002] The paint is applied on the surface of the object to form a solid, strong and continuous coating, which can protect and decorate the coated object, or make it insulating, rust-proof, mildew-proof, heat-resistant, and wear-resistant and other special functions. Patent No. 200410014489.4 Invention Patent "Insulating Powder Coating for Electromagnetic Wires" discloses an insulating powder coating used in electrostatic coating process for electromagnetic wires. A special property of the coating film or coating of this insulating powder coating is electrical insulating properties. The powder coating is composed of resin, curing agent and auxiliary materials, among which the amount of resin and curing agent with higher price accounts for 98%, while the amount of filler with...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B32B27/38B32B27/18C09D163/00C09D5/03C09D5/25C09D5/08C09D163/02C09D163/04C09D7/12

Inventor 吴金岳

Owner NINGBO KEXIN CORROSION CONTROL ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com