Preparation of nano graphite carbon colloidal SOL by pulse electrode process

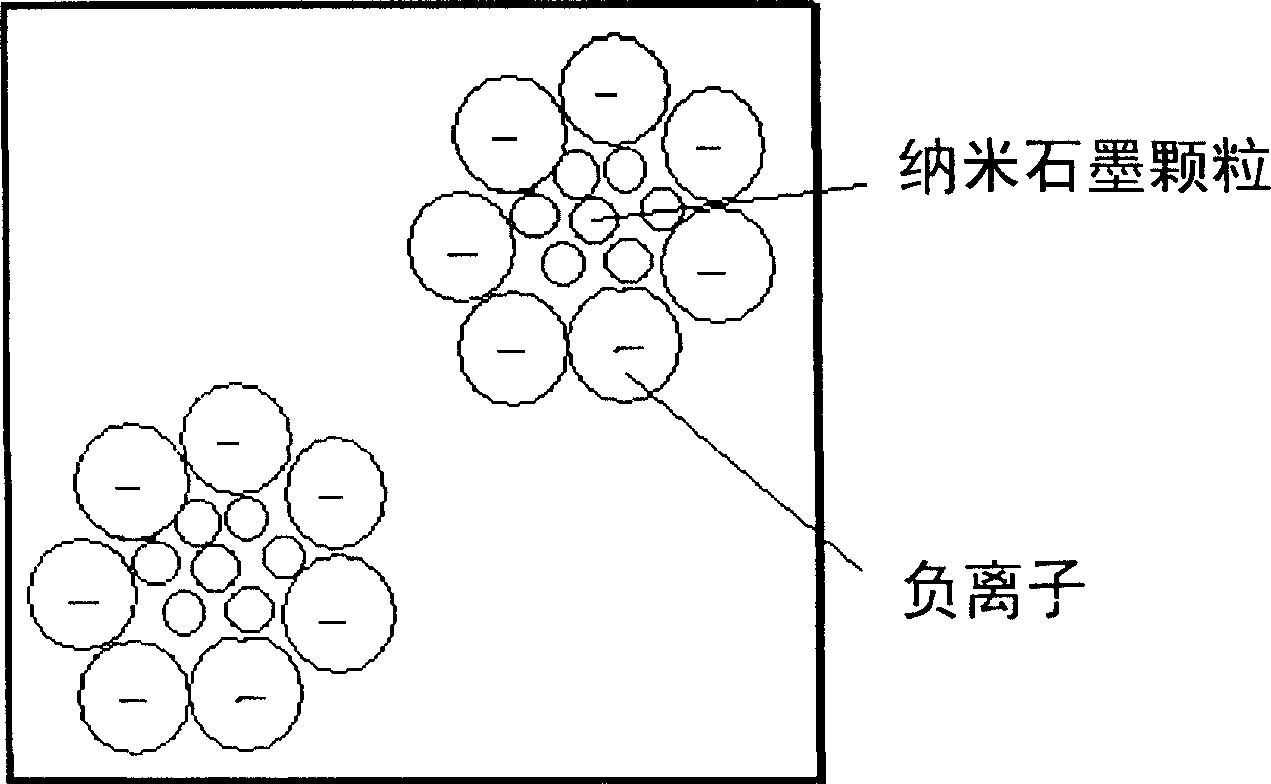

A nano-graphite and carbon sol technology, applied in the electrolysis process, electrolysis components and other directions, can solve the problems of low efficiency of graphite sol and inability to obtain graphite sol, and achieve the effect of good surface modification effect, no industrial pollution and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

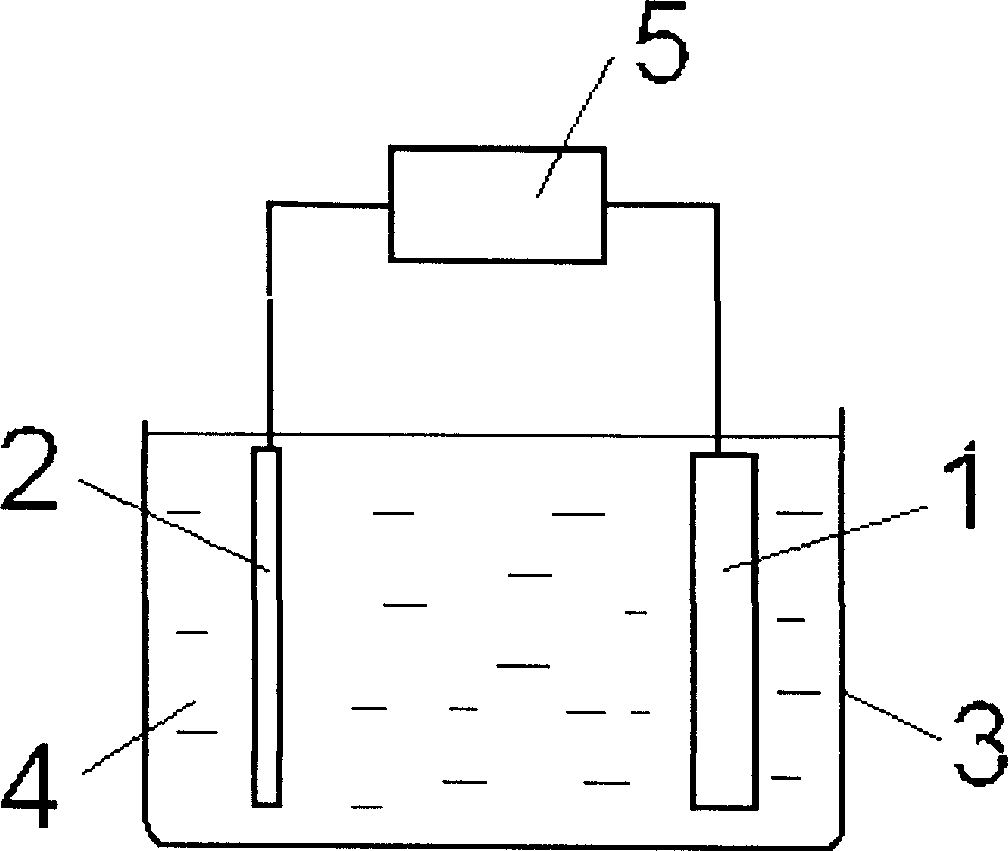

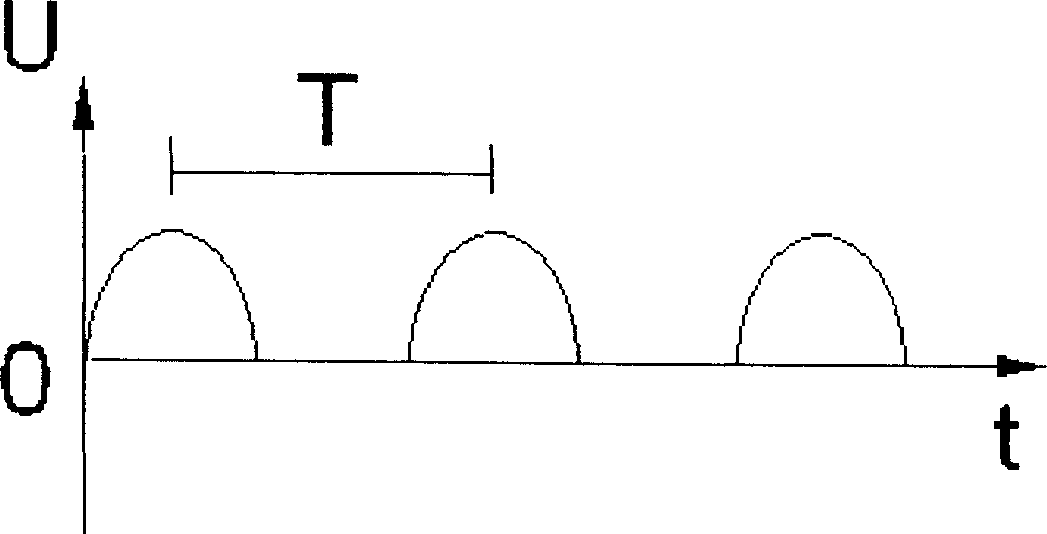

[0039] Get 4 high-purity graphite carbon plates (200mm × 200mm × 50mm, Jilin Carbon Group Shanghai Carbon Plant) as anode 11, 4 stainless steel plates (200mm × 200mm × 2mm, commercially available) as cathode 12, 7 polyethylene Mesh plate (thickness 1mm, mesh diameter 10mm, commercially available) 16, according to Figure 4 To form a system, the anode 11, the polyethylene mesh plate 16 and the cathode 12 are repeatedly arranged without intervals. The pulse power supply 15 generates as figure 2 For the pulse voltage shown, the pulse period is 0.05 seconds, and the effective voltage is 5V.

[0040] Add sulfuric acid to deionized water to adjust its pH to 2.5, add sodium chloride to adjust the resistance of the solution, so that when the effective value of the pulse voltage is 5V, the current of the system is 10A.

[0041] Apply pulse voltage for 10 days to obtain graphite carbon sol A, the sol concentration is about 2% (weight).

[0042] The obtained graphite carbon sol A was...

Embodiment 2

[0044] Take 4 high-purity graphite carbon plates (200mm×200mm×50mm) as anodes 11, 4 graphite carbon plates (200mm×200mm×30mm) as cathodes 12, and 7 polyethylene mesh plates (thickness 1mm, mesh diameter 10mm) )16, according to Figure 4 To form a system, the anode 11, the polyethylene mesh plate 16 and the cathode 12 are repeatedly arranged without intervals. The pulse power supply 15 generates as figure 2 For the pulse voltage shown, the pulse period is 0.5 seconds, and the effective voltage is 3V.

[0045] Add sodium hydroxide to deionized water to adjust its pH to 8, add sodium chloride to adjust the resistance of the solution, so that when the effective value of the pulse voltage is 3V, the current of the system is 8A.

[0046] Apply pulse voltage for 15 days to obtain graphitic carbon sol B, the sol concentration is about 1.5% (weight).

[0047] The obtained graphite carbon sol B was stored for several months without precipitation or delamination.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com