Method for preparing novel packaging material with frosted effect

A packaging material and frosted technology, which is applied to patterns characterized by light projection effects, processes used to produce decorative surface effects, decorative arts, etc. , low brightness and gloss, etc., to solve the problem of poor re-modification performance, unique packaging effect, and good surface modification performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention provides a method for preparing a new type of matte effect packaging material, including the following process flow: design matte effect patterns, select optical effects based on the effect patterns, quantify the optical effects, simulate the optical effects to determine the matte effects and images Unit, and then group the image units and make a plate by photolithography to prepare a master, and finally copy the frosted information on the master to the substrate to obtain a packaging material with a new frosted effect.

[0035] The specific process steps are as follows: matte effect design: use graphic processing software to design the matte effect required; optical effect selection: select the corresponding optical effect expression form according to the matte effect designed; optical effect quantification: quantify optics according to the matte effect The effect of grayscale, angle, depth and other parameters; optical effect simulation: use the corr...

Embodiment 1

[0045] Step 1: Design

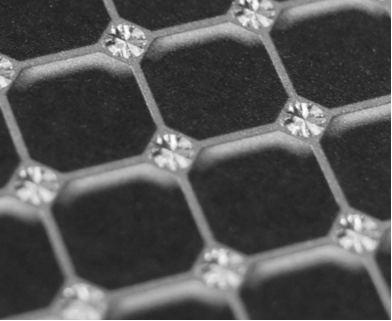

[0046] Use graphic processing software to design a rainbow matte effect, such as figure 1 As shown, the matte effect is a full-page effect, with silver-white highlights in some areas. In the absence of particularly bright light, three-dimensional small particles can be perceived in the visual effect, and random silver-white dots can be seen at the same time. When under bright light conditions, in addition to the silver frosted effect, you can also observe random flashing points of rainbow light. Has a rainbow matte effect.

[0047] Step 2: Optical effect selection

[0048] According to the matte effect of the design, two optical effects of lens and grating are selected.

[0049] Step 3: Quantification of optical effects

[0050] According to the frosted effect, the two optical effects of quantization lens and grating, the lens is a non-circular structure Fresnel structure, the grating is a platinum beam, the lens and grating parameters: gray value range 45-200,...

Embodiment 2

[0064] Step 1: Design

[0065] Use graphic processing software to design a highlight matte effect, such as image 3 As shown, the frosting effect is a full-page effect. In the absence of particularly bright light, three-dimensional small particles can be perceived in the visual effect. When under bright light conditions, in addition to the three-dimensional frosting effect, you can also observe The effect of glittering particles.

[0066] Step 2: Optical effect selection

[0067] According to the matte effect of the design, three kinds of optical effects are selected: lens, grating and sand silver.

[0068] Step 3: Quantification of optical effects

[0069] According to the matte effect, the three optical effects of lens, grating and sand silver are quantified. The lens is a non-circular Fresnel structure, the grating is a dynamic grating, and the sand silver is a dynamic sand silver. The lens, grating and sand silver parameters: gray value range 45 -200, the angle value range is 0-18...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| greyscale | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com