a tic-cr 7 c 3 -cnts/iron-based surface composite material and preparation method thereof

A surface composite material, tic-cr7c3-cnts technology, applied in the field of TiC-Cr7C3-CNTs/iron-based surface composite materials and its preparation, can solve the problems of weakening the wettability of agglomeration tendency and difficult to avoid agglomeration, and achieve high Hardness, high process controllability, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

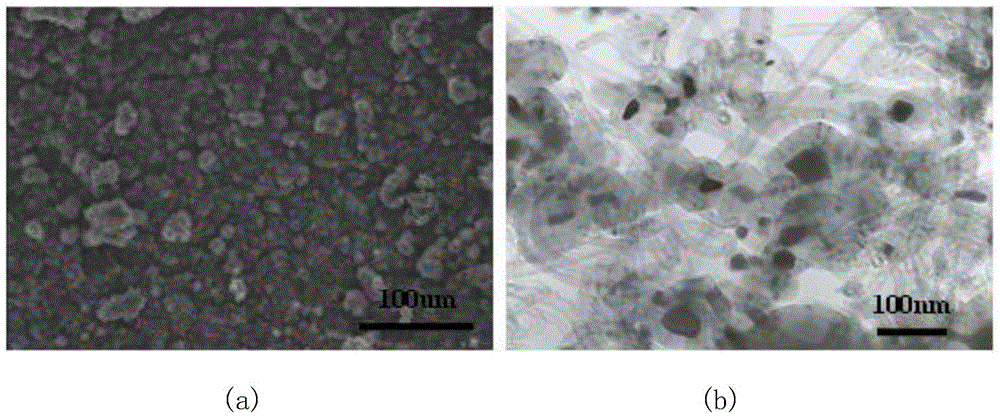

[0034] The surface of 304 stainless steel with a size of 50mm×50mm×8mm is subjected to 600 # Polished with water sandpaper, ultrasonically cleaned, and dried with hot air, the weight is 112.580g. Then put the sample into high temperature furnace, 680℃, 68%CO-31%H 2 -1%H 2 O supersaturated carbon atmosphere reacted for 20 hours, and evenly distributed CNTs were grown on the surface of the sample in situ. Then weigh 113.329g, and the incremental part before and after the reaction is the weight of the incremental carbon. figure 1 In-situ self-generated CNTs on the surface of 304 stainless steel S Morphology, among which, picture (a) is the SEM image of 304 steel surface; picture (b) is the CNT image of 304 steel surface S TEM image, as can be seen from the figure, CNT S Uniform distribution, uniform particle size, no agglomeration.

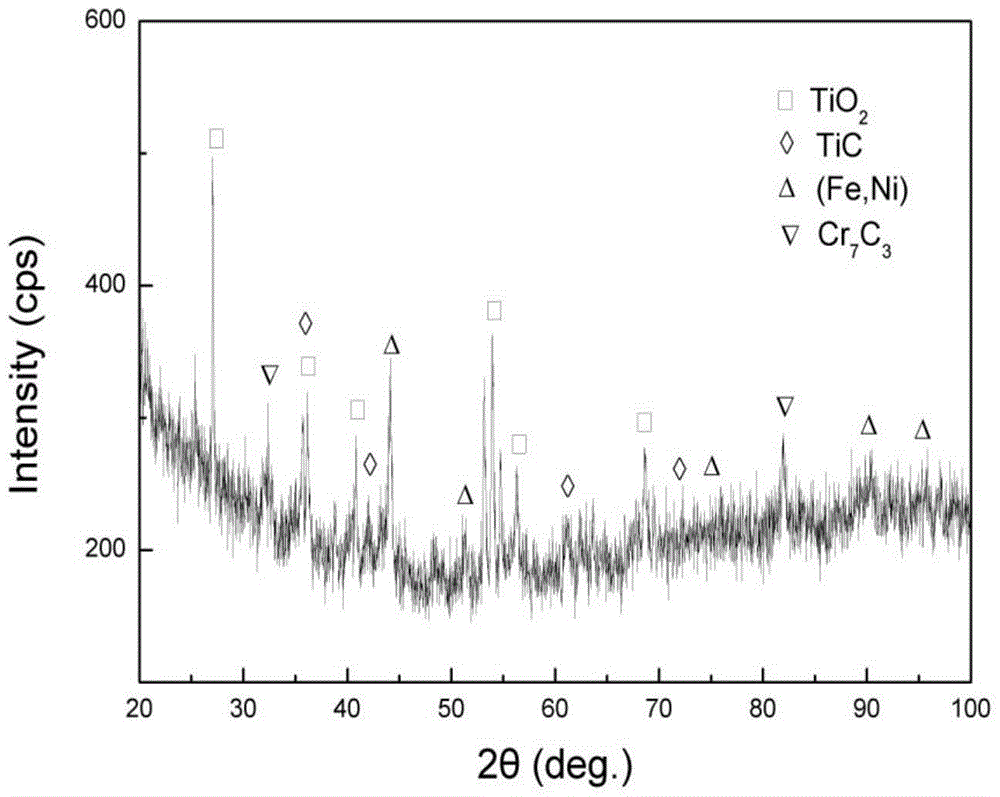

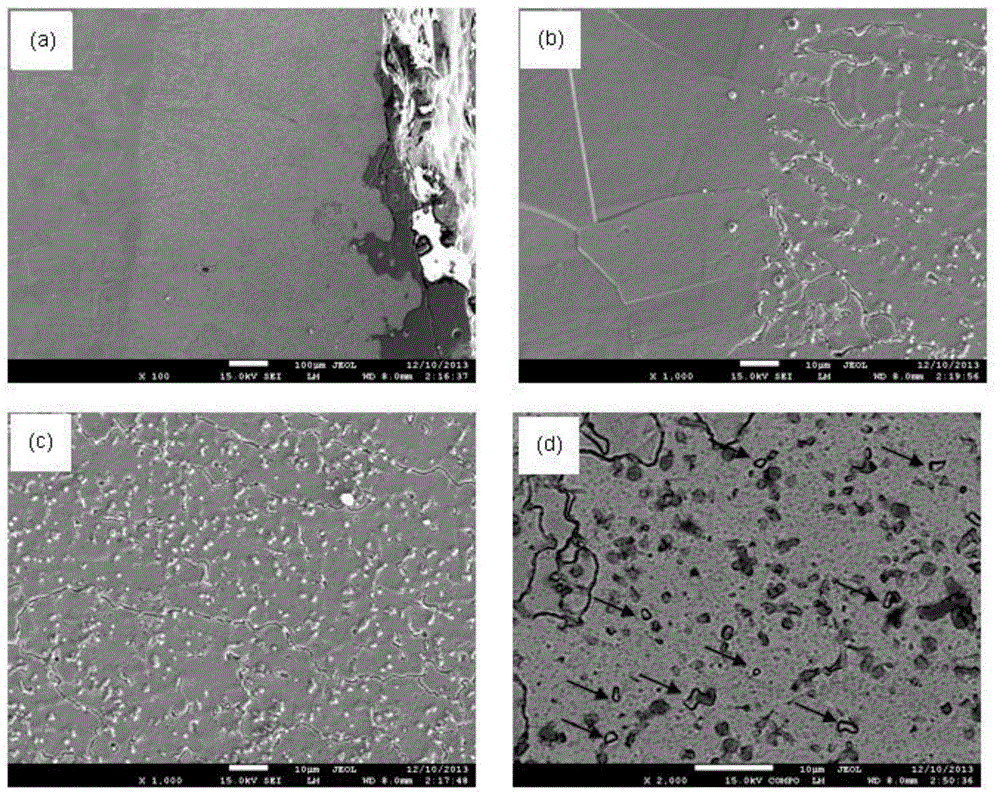

[0035] Then adopt laser cladding synchronous powder feeding technology, the reaction conditions are laser power of 3000W, spot diameter of 10m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com