Preparation method for silane coupling agent modified CB/CFDSF/AG-80 epoxy resin composite material

A technology of silane coupling agent and epoxy resin, which is applied in the field of composite materials, can solve the problems of insufficient mechanical properties such as strength, affecting the performance of the composite material matrix, and the physical properties of the composite material system, so as to ensure stability and good electrical conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] For the modification treatment of carbon black (CB), the inventor of the present application has studied the use of silane coupling agent for modification treatment and the use of oxidant for modification treatment. The present invention protects the use of silane coupling agent to modify CB / CFDSF / AG -80 Preparation method of epoxy resin composite material;

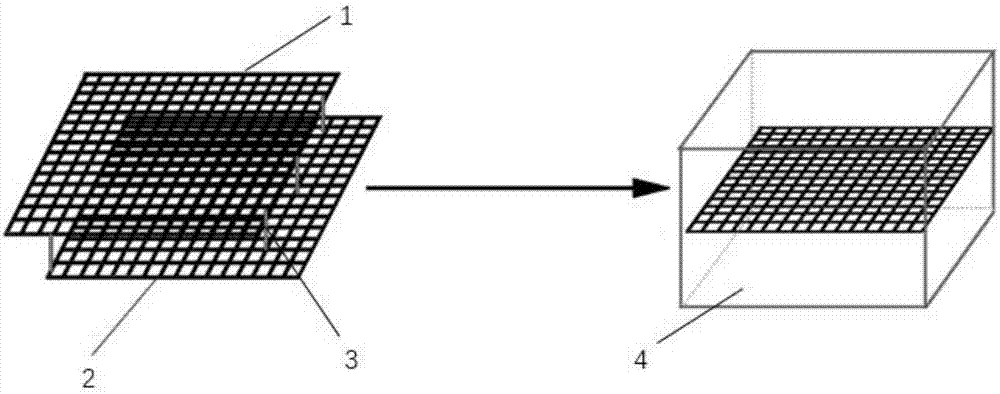

[0042] A preparation method for preparing silane coupling agent modified CB / CFDSF / AG-80 epoxy resin composite material, mainly comprising the following steps:

[0043] 1. Modification of carbon black (CB) with silane coupling agent

[0044] The carbon black (CB) is modified with a silane coupling agent. First, the carbon black is preheated at 40°C for 5 minutes, and a certain amount of silane coupling agent dissolved in water is added. The mass fraction of the silane coupling agent is 1%, heated to 75°C, mechanically stirred for 0.5h, treated at 120°C for 2h, dried carbon black, and ground for 0.5h to obtain silan...

Embodiment 2

[0051] Modification of carbon black (CB) The inventors of the present application have studied the use of silane coupling agents for modification and the use of oxidants for modification. The present invention protects the use of silane coupling agents to modify CB / CFDSF / AG- 80 Preparation method of epoxy resin composite material;

[0052] A preparation method for preparing silane coupling agent modified CB / CFDSF / AG-80 epoxy resin composite material, mainly comprising the following steps:

[0053] 1. Modification of carbon black (CB) with silane coupling agent

[0054] The carbon black (CB) is modified with a silane coupling agent. First, the carbon black is preheated at 45°C for 8 minutes, and a certain amount of silane coupling agent dissolved in water is added. The mass fraction of the silane coupling agent is 2%, raise the temperature to 80°C, mechanically stir for 1h, treat at 125°C for 2.5h, dry the carbon black, and grind for 1h to obtain silane coupling agent modified...

Embodiment 3

[0061] Modification of carbon black (CB) The inventors of the present application have studied the use of silane coupling agents for modification and the use of oxidants for modification. The present invention protects the use of silane coupling agents to modify CB / CFDSF / AG- 80 Preparation method of epoxy resin composite material;

[0062] A preparation method for preparing silane coupling agent modified CB / CFDSF / AG-80 epoxy resin composite material, mainly comprising the following steps:

[0063] 1. Modification of carbon black (CB) with silane coupling agent

[0064] The carbon black (CB) is modified with a silane coupling agent. First, the carbon black is preheated at 50°C for 10 minutes, and a certain amount of silane coupling agent dissolved in water is added. The mass fraction of the silane coupling agent is 3%, raised the temperature to 85°C, mechanically stirred for 1h, treated at 130°C for 3h, dried the carbon black, and ground it for 1h to obtain silane coupling age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com