Quasi-molecule ultraviolet source treatment method and device for textile surface modifying

An ultraviolet light source, surface modification technology, applied in physical treatment, fiber treatment, textile and papermaking, etc., can solve the problems affecting resin infiltration, bonding performance, low content of polar groups on the fiber surface, etc., and achieve apparent dyeing. Effects of depth improvement, surface hydrophilicity improvement, surface hydrophilicity improvement, and apparent dye depth improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

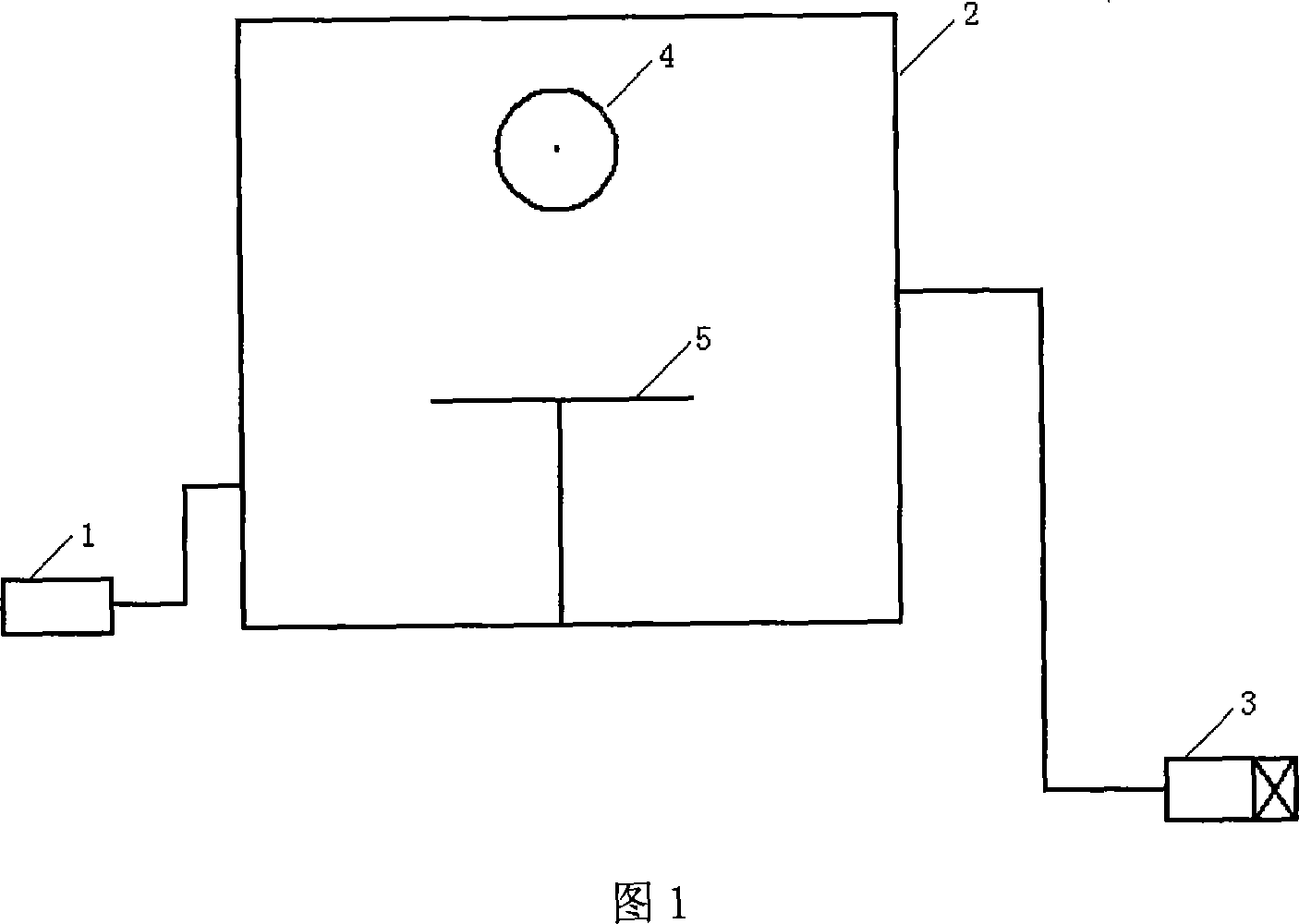

[0023] As shown in Figure 1, a kind of device that is used for the treatment of excimer ultraviolet light source of textile surface modification, comprises three parts of power system 1, excimer ultraviolet light source treatment room 2 and pressure control system 3, described excimer ultraviolet The light source processing chamber 2 is equipped with an excimer ultraviolet lamp tube 4 and a sample placement platform 5 .

[0024] During use, place the woven twill wool fabric on the sample placement platform of the device provided by the present invention, adjust the distance between the excimer ultraviolet lamp tube and the fabric to be 0.5cm, adjust the pressure in the excimer ultraviolet light source treatment chamber to be 100KPa, open Power supply, control the irradiation time to 8min. The surface properties and breaking strength of wool fabrics after treatment are shown in Table 1. After irradiation treatment, the scale layer on the wool fiber surface was etched, and the ...

Embodiment 2

[0028] Place the woven plain aramid fabric on the sample placement platform of the device provided by the present invention, adjust the distance between the excimer ultraviolet lamp tube and the fabric to be 1cm, adjust the pressure in the excimer ultraviolet light source treatment chamber to be 80KPa, turn on the power, Control the irradiation time to 5min. The surface properties and breaking strength of the treated aramid fabric are shown in Table 2. After irradiation treatment, the smooth surface of the fiber was etched rough and polar groups were introduced into the surface.

[0029] Table 2

[0030] Performance

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com