Patents

Literature

36 results about "Excimer laser irradiation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phase shift mask blank, phase shift mask, and method for manufacturing the same

InactiveUS20020061452A1Semiconductor/solid-state device manufacturingGlass/slag layered productsOxygenSemi transparent

An object of the present invention is to provide a half-tone phase shift mask blank and a half-tone phase shift mask of which a translucent film has improved acid resistance, alkali resistance and resistance to excimer laser irradiation while maintaining the internal stress of the film within an acceptable range for the intended use. To achieve the aforementioned object, the present invention provides a half-tone phase shift mask blank which comprises a transparent substrate having provided thereon a translucent film comprising at least one thin layer containing silicon and at least one of nitrogen and oxygen and which is to be exposed to light whose center wavelength is 248 nm or shorter, wherein said translucent film is dense such that it has a center-line surface roughness (Ra) of 0.3 nm or smaller.

Owner:HOYA CORP

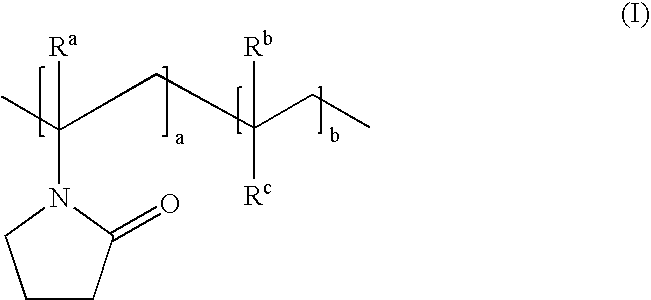

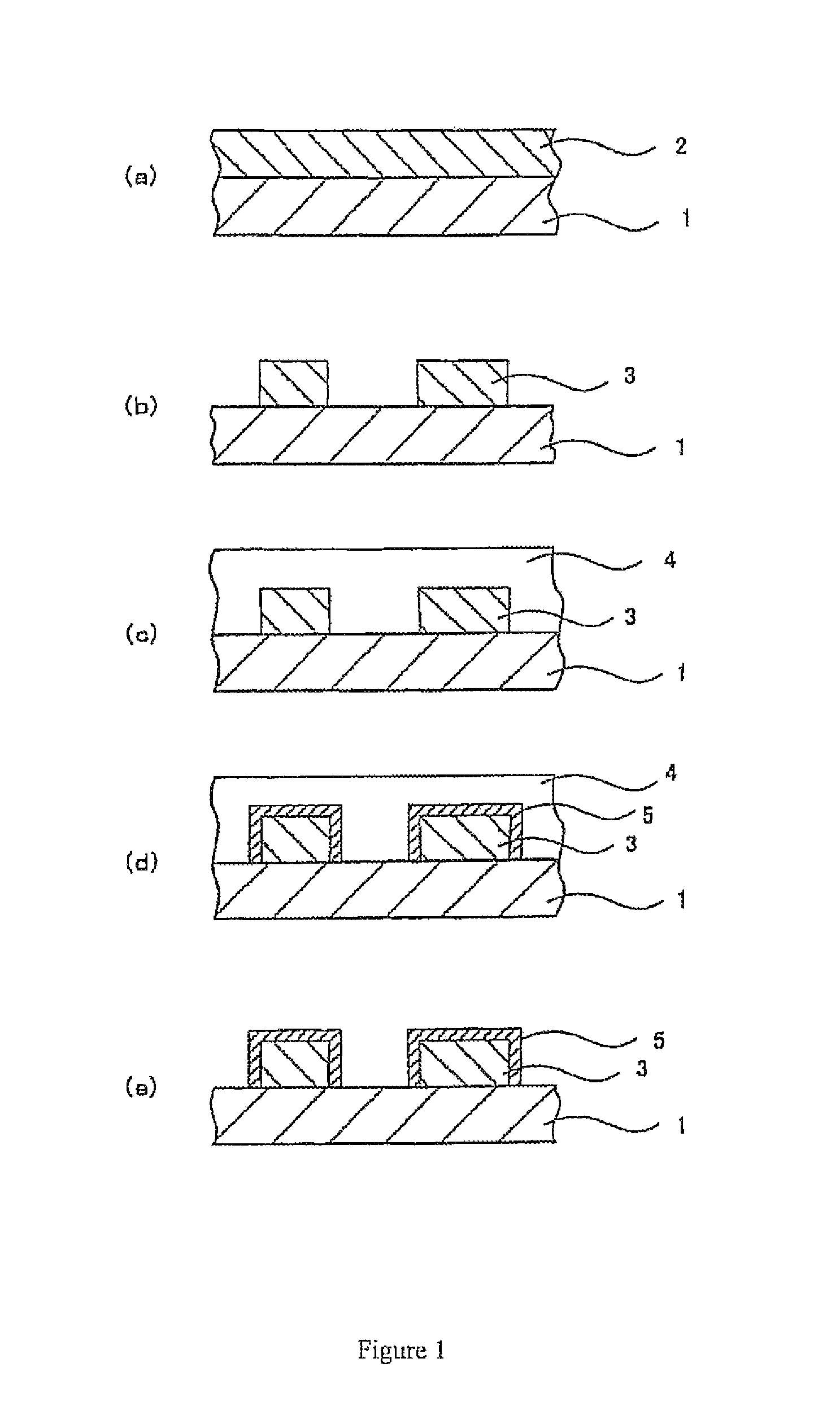

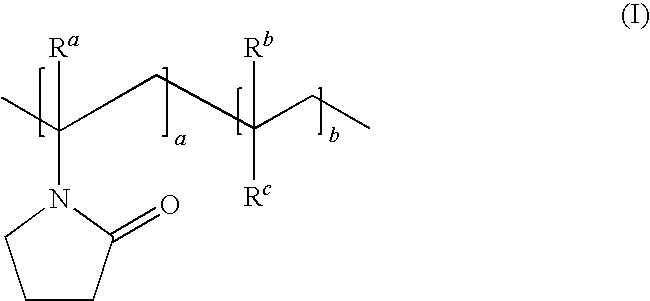

Water Soluble Resin Composition and Method for Pattern Formation Using the Same

InactiveUS20080193880A1Efficient preparationHigh yieldPhotosensitive materialsRadiation applicationsResistHigh density

In the present invention, in a water soluble resin composition for use in a method for pattern formation in which a covering layer is provided on a resist pattern formed of a radiation-sensitive resin composition capable of coping with ArF exposure to increase the width of the resist pattern and thus to realize effective formation of higher density trench or hole pattern, the size reduction level of the resist pattern layer can be further increased as compared with that in the prior art technique, and, in addition, the size reduction level dependency of the coarse-and-fine resist pattern can be reduced. A method for pattern formation using the water soluble resin composition is also provided. The water soluble resin composition which is usable for the method for pattern formation applicable to ArF excimer laser irradiation comprises a water soluble resin, an acid generating agent capable of generating an acid upon heating, a surfactant, a crosslinking agent, and a water-containing solvent.

Owner:MERCK PATENT GMBH

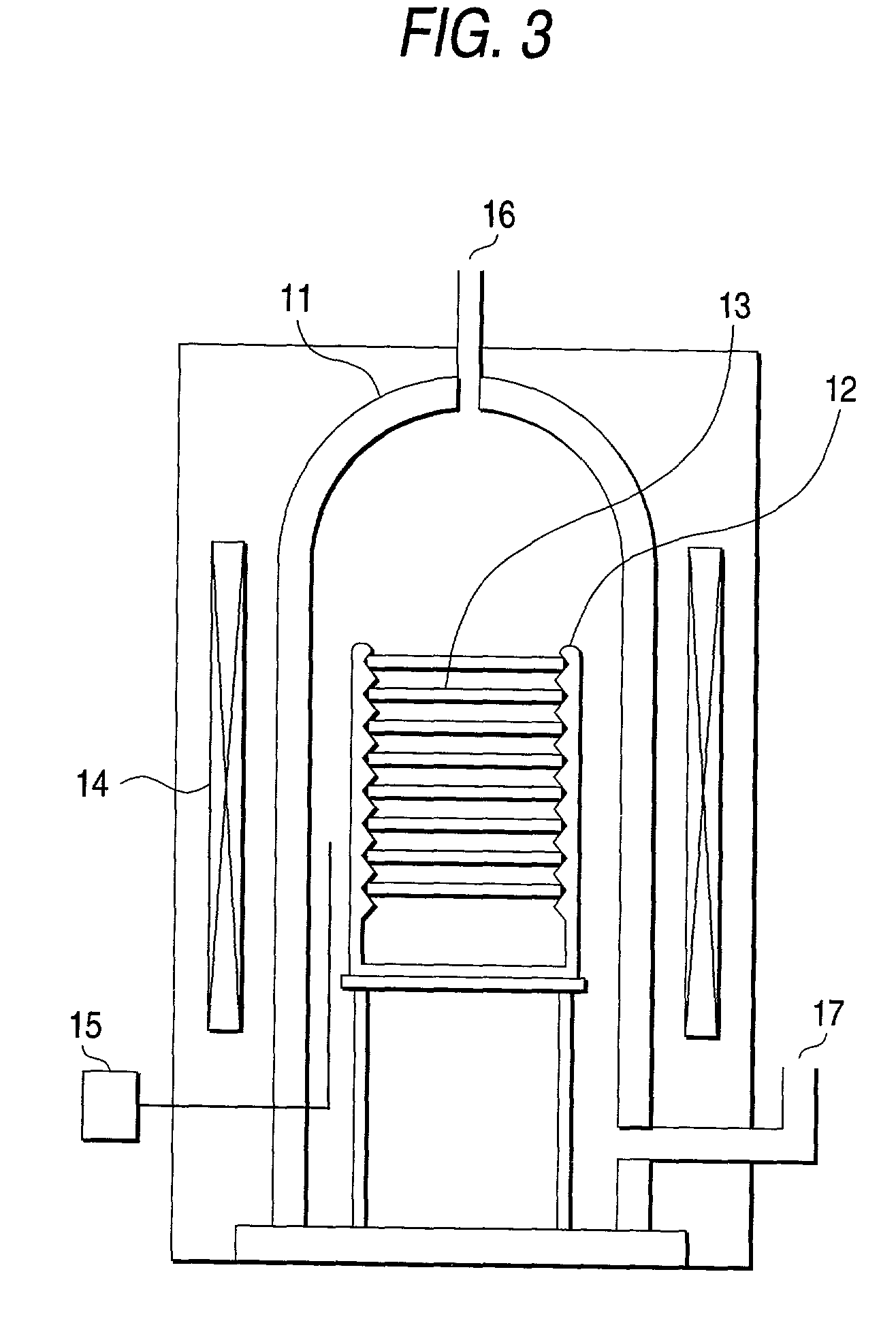

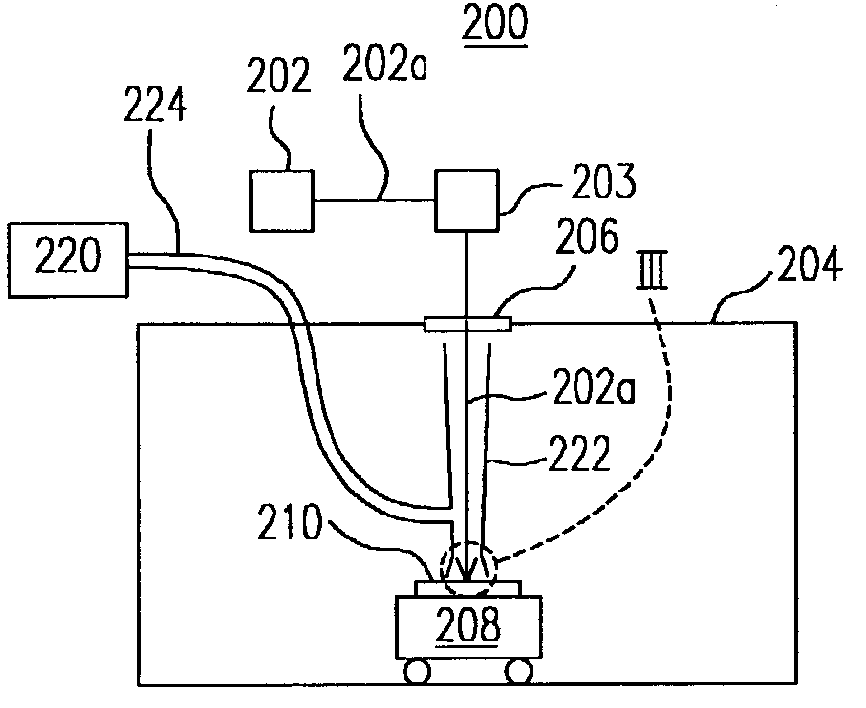

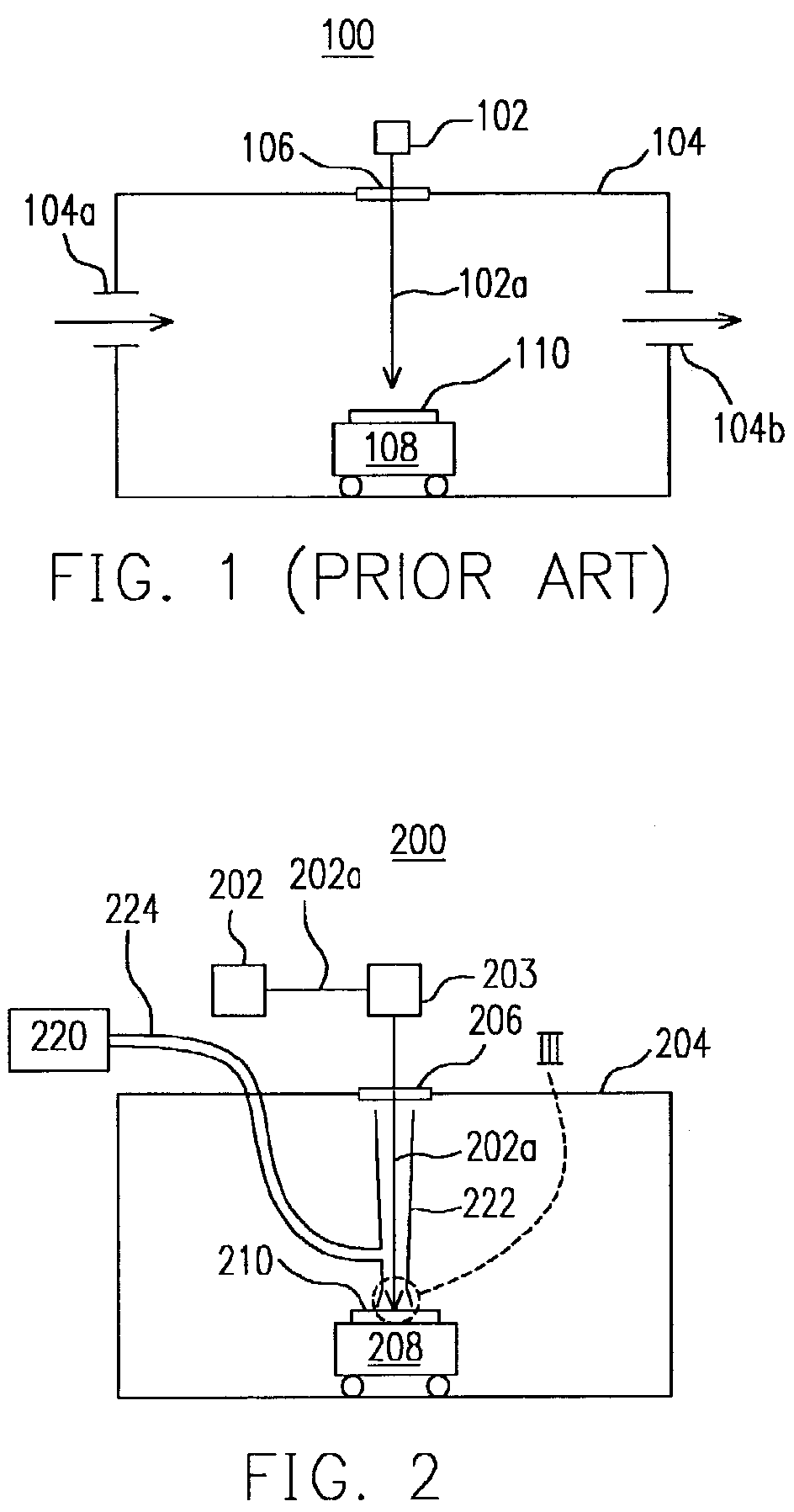

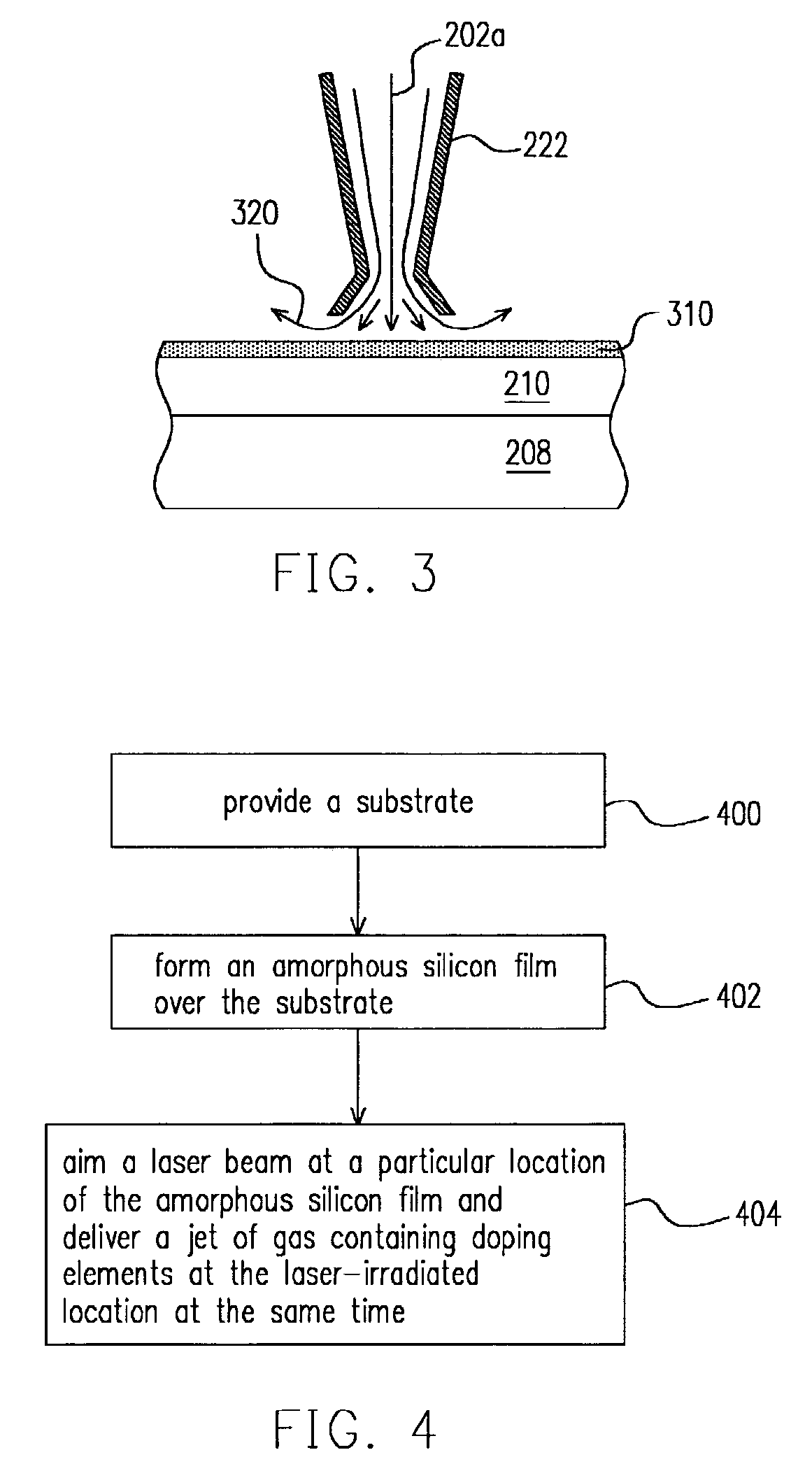

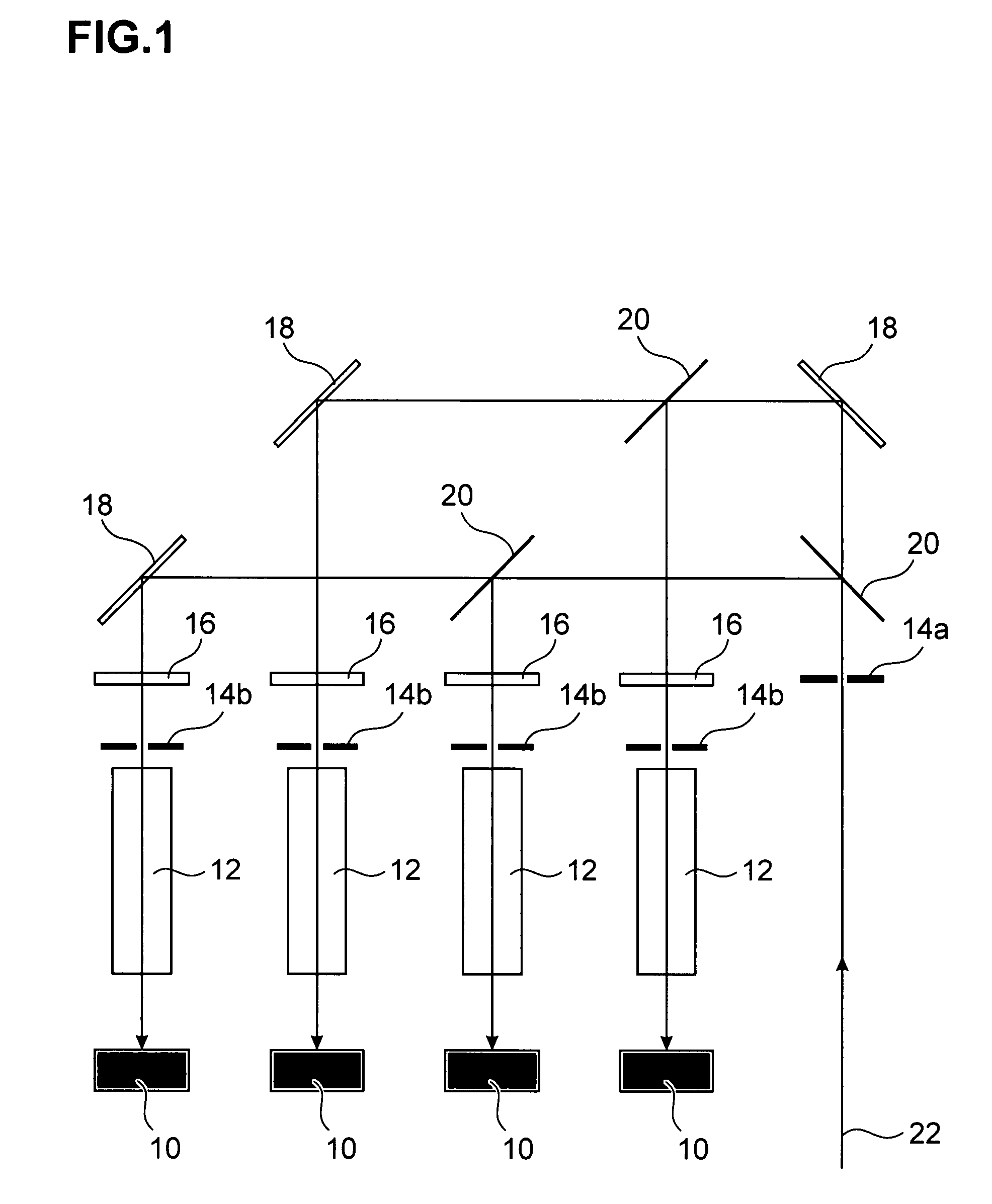

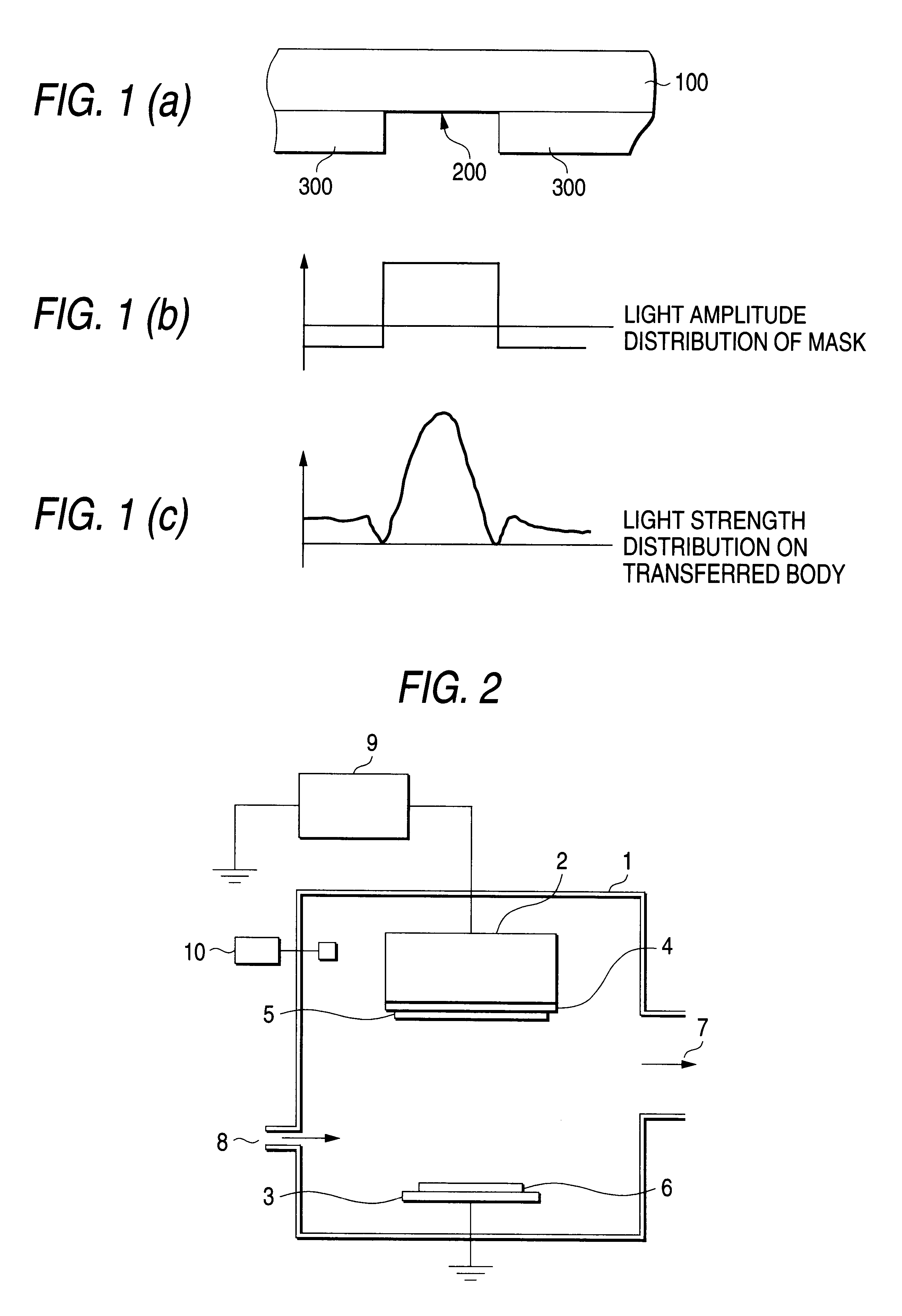

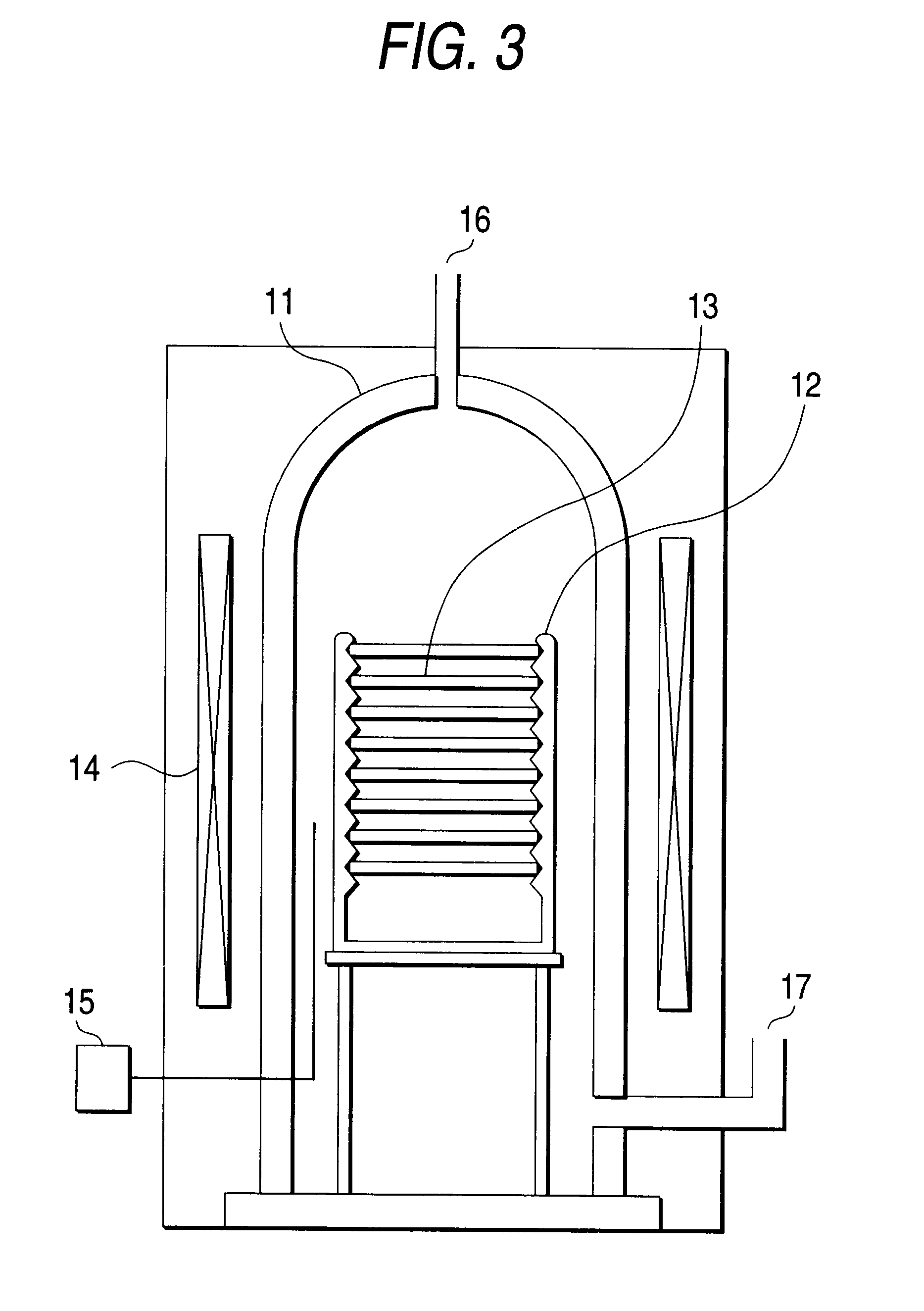

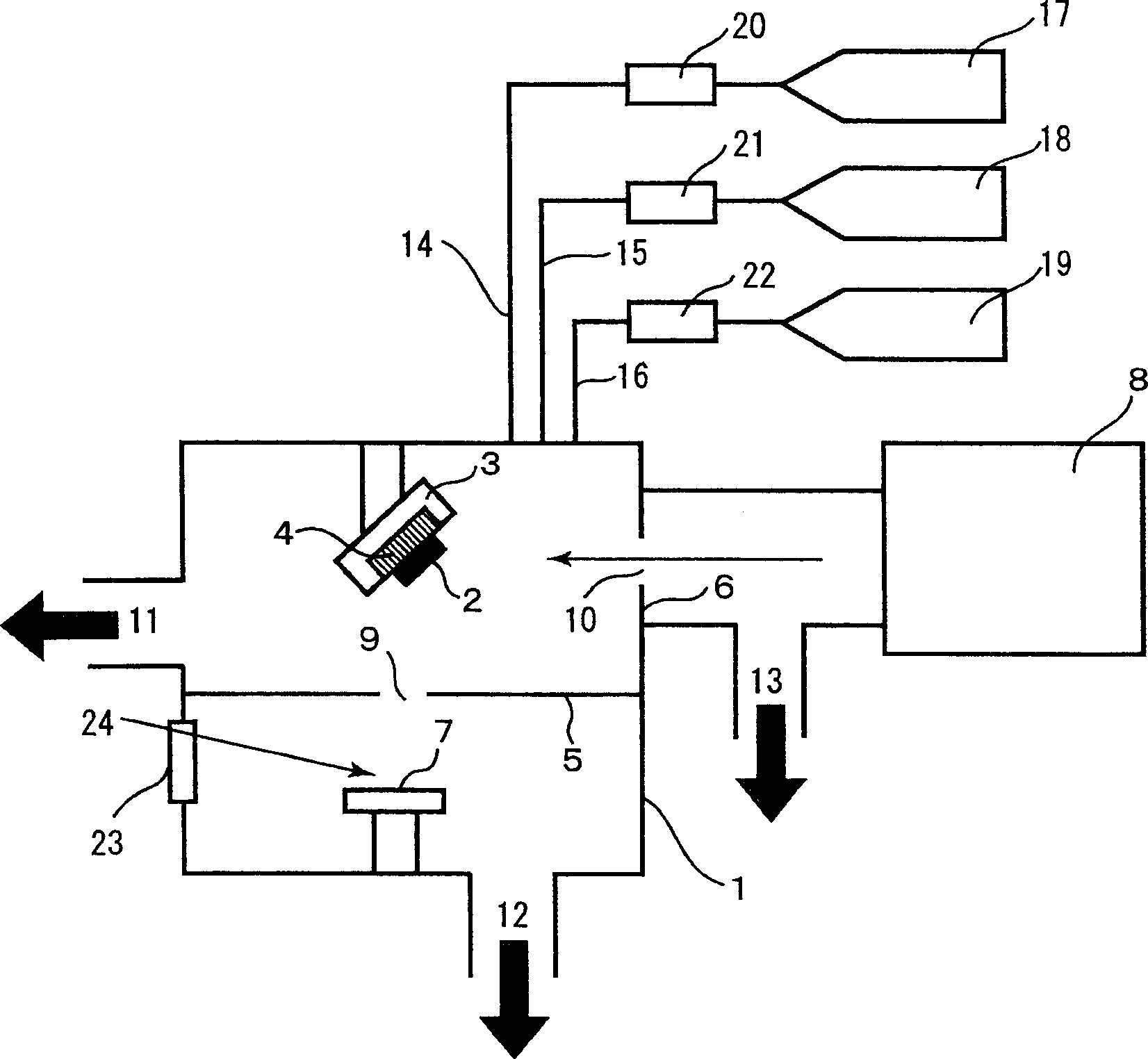

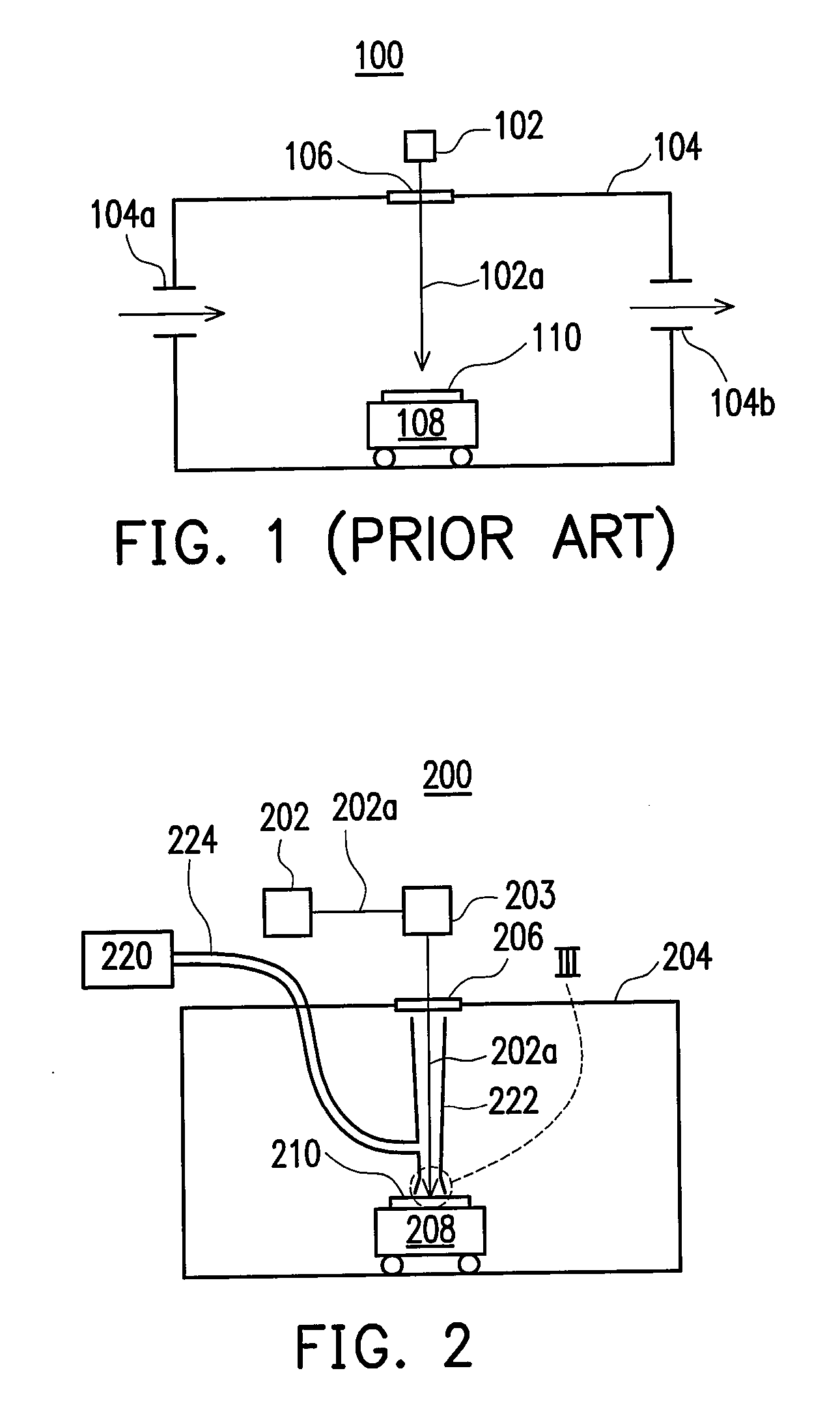

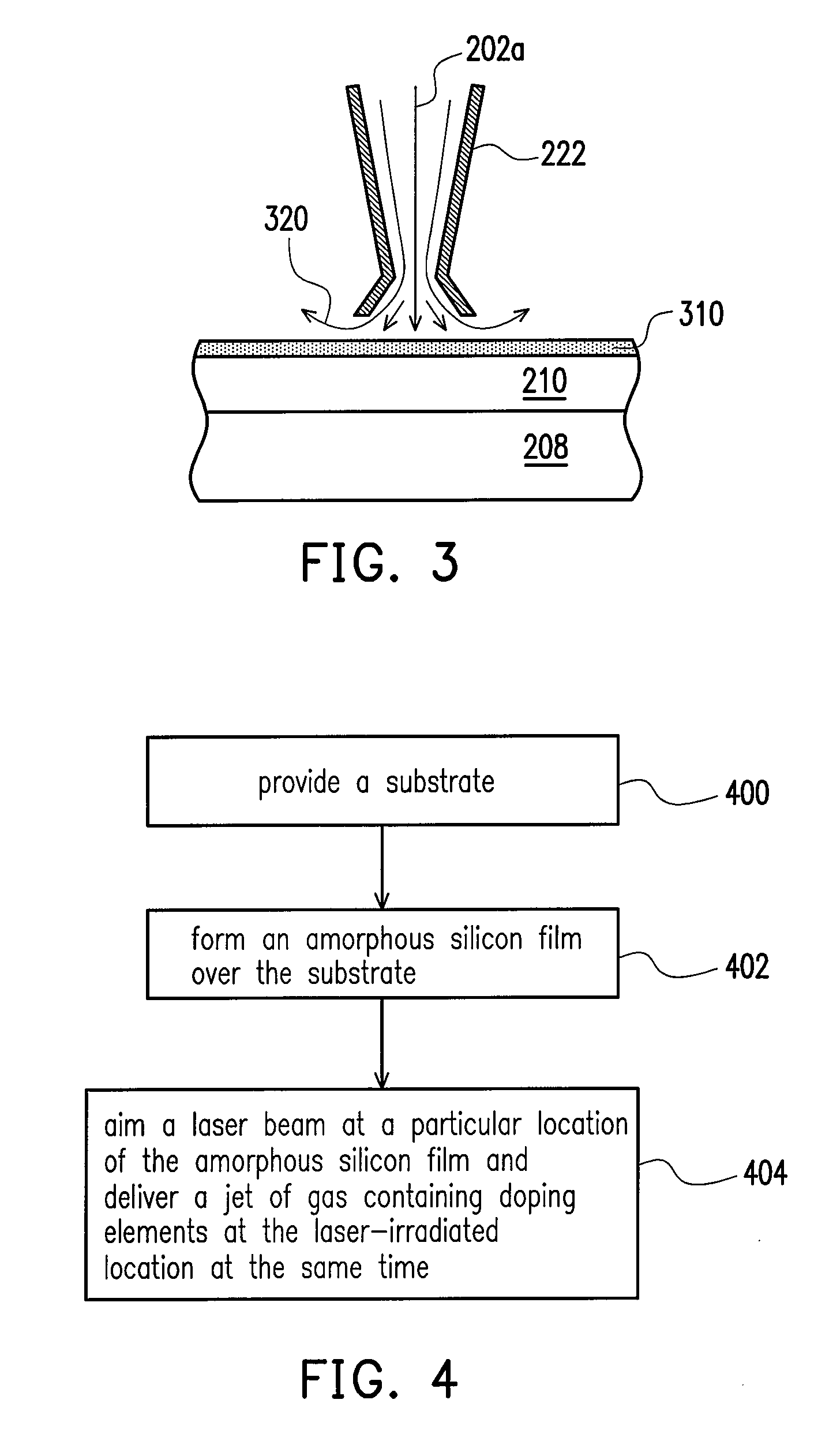

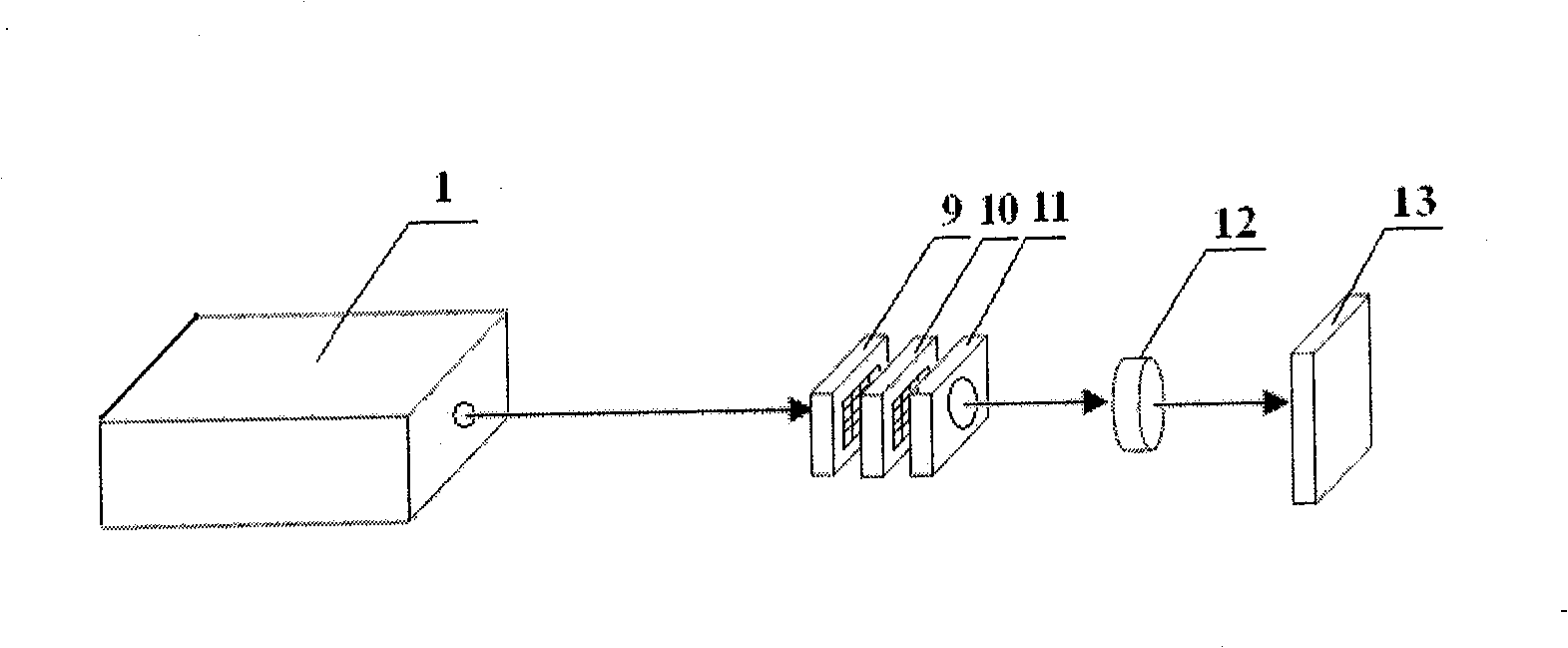

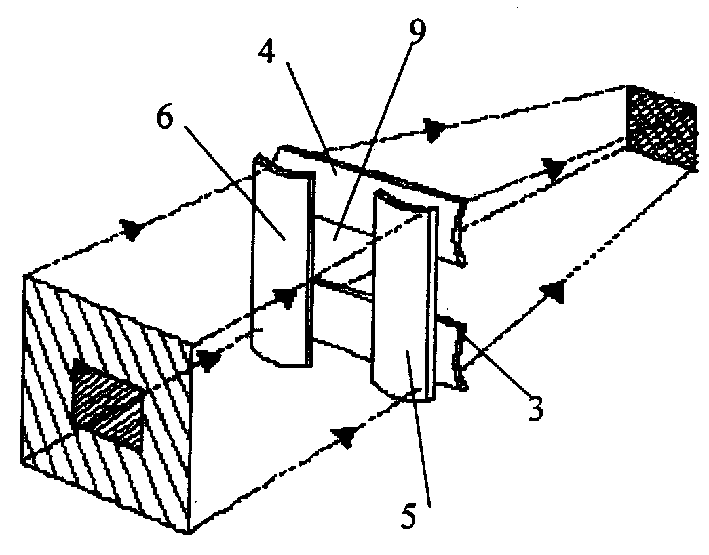

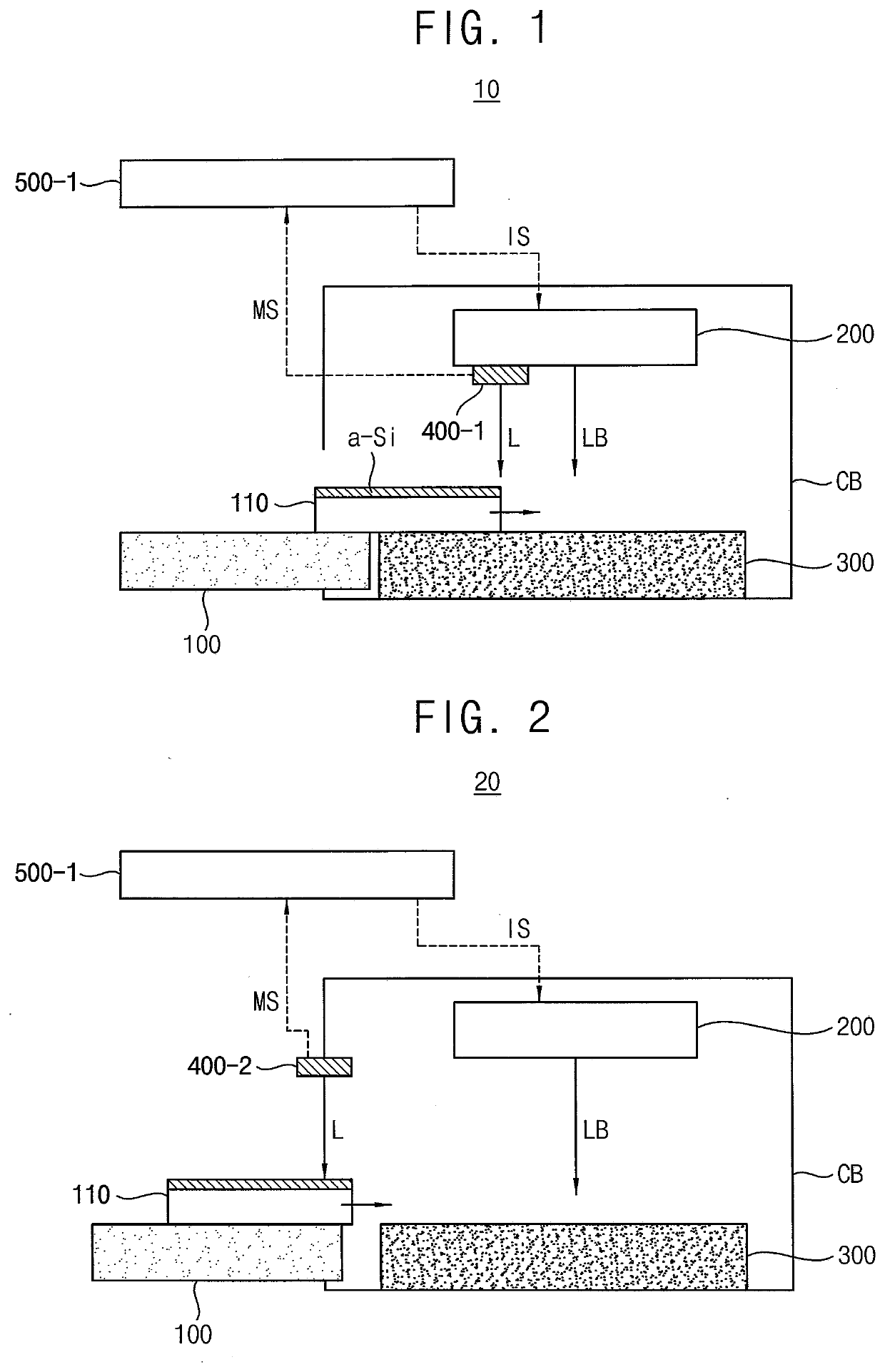

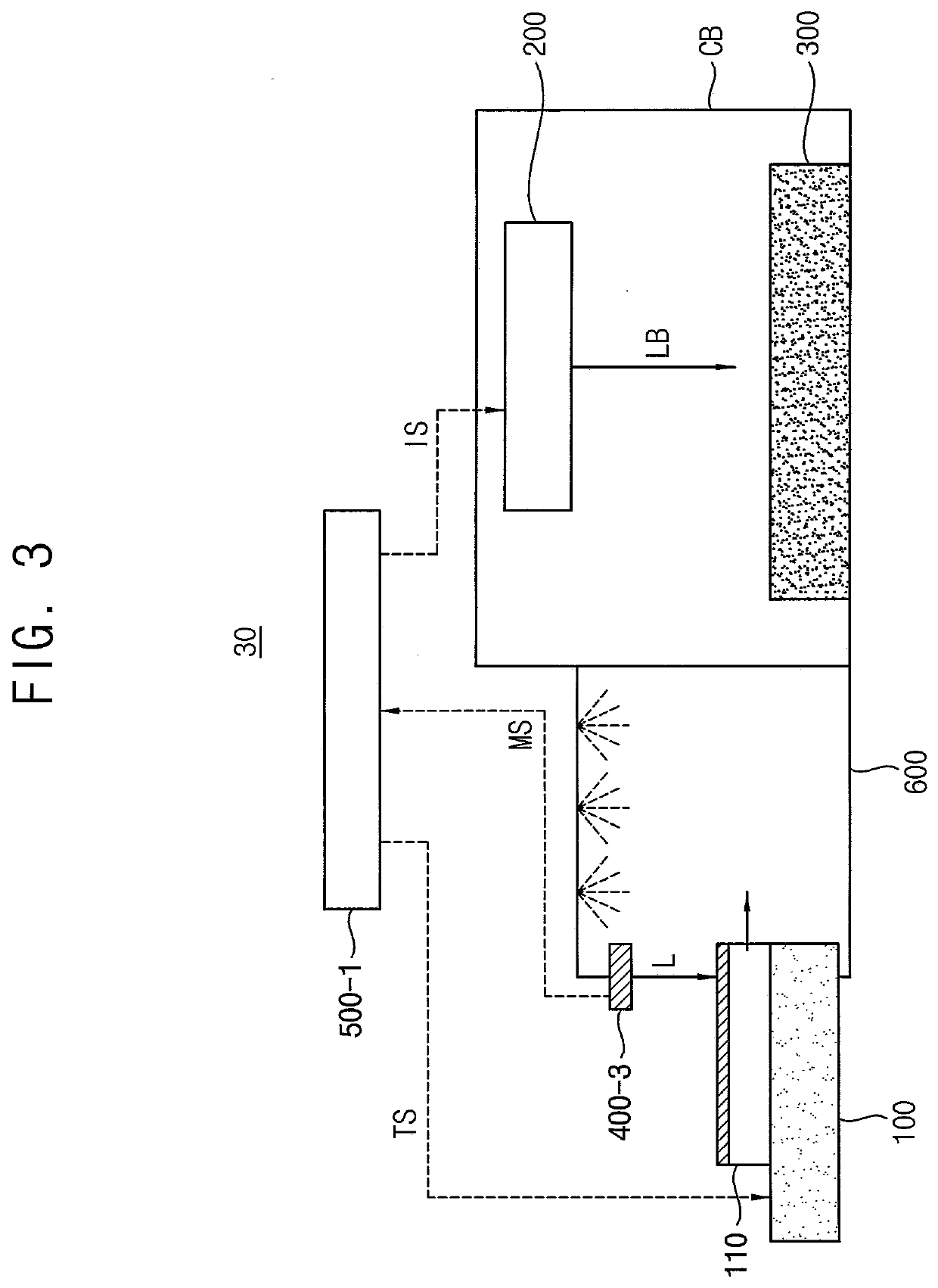

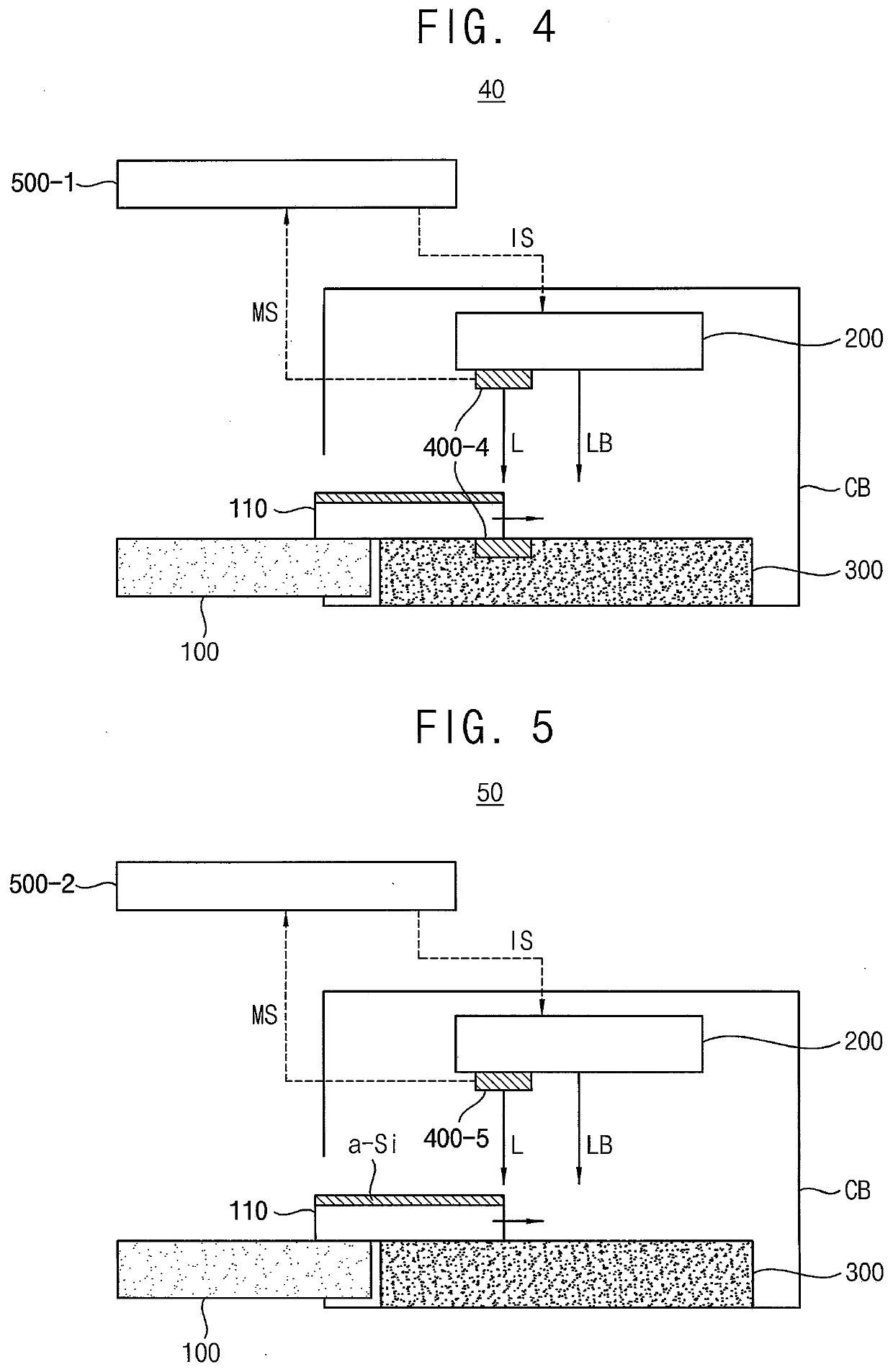

Laser annealing apparatus

ActiveUS7247812B2Minimize changesImprove accuracySemiconductor/solid-state device manufacturingChemical vapor deposition coatingOptoelectronicsGas supply

An excimer laser annealing apparatus and the application of the same for stabilizing the atmosphere surrounding an area irradiated by an excimer laser. The apparatus includes a chamber, a gas diversion nozzle, an excimer laser and a gas supply device. The gas diversion nozzle is positioned inside the chamber. The laser beam produced by the excimer laser passes through the gas diversion nozzle. The gas supply device connects with the gas diversion nozzle for providing a jet of gas to the laser-irradiated area and carrying away any pollutants from the irradiated area.

Owner:AU OPTRONICS CORP

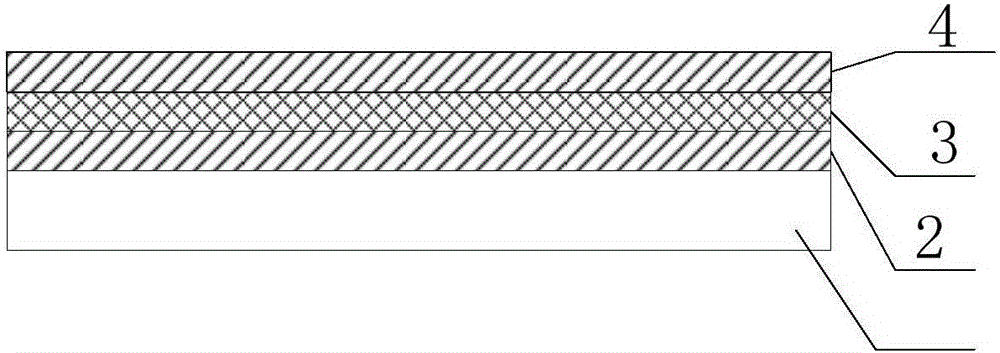

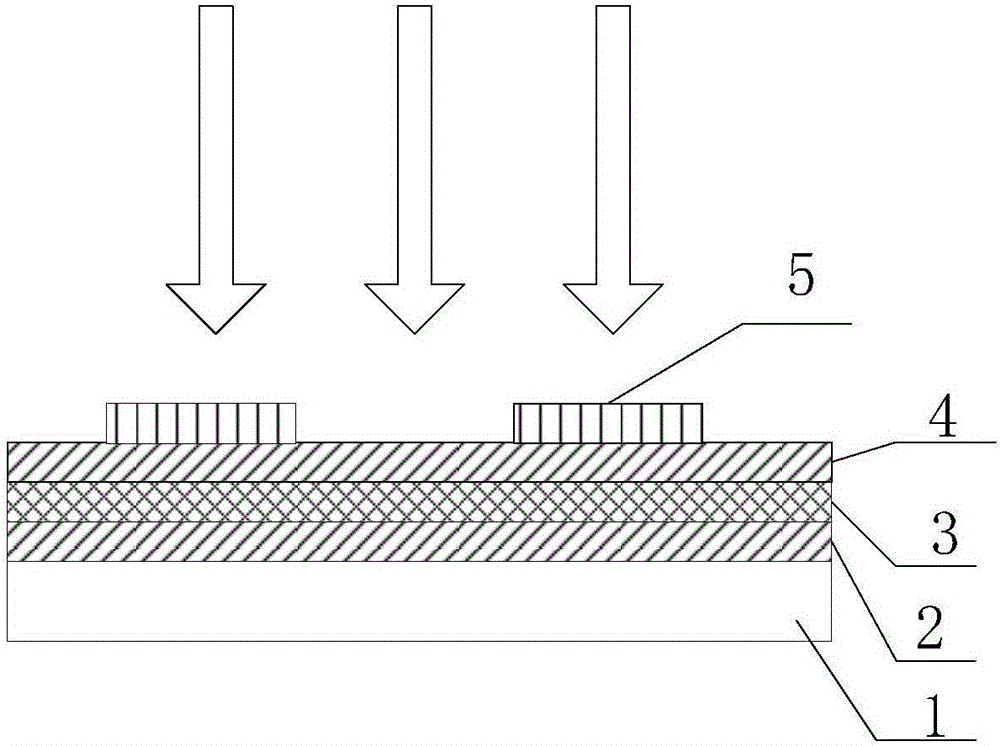

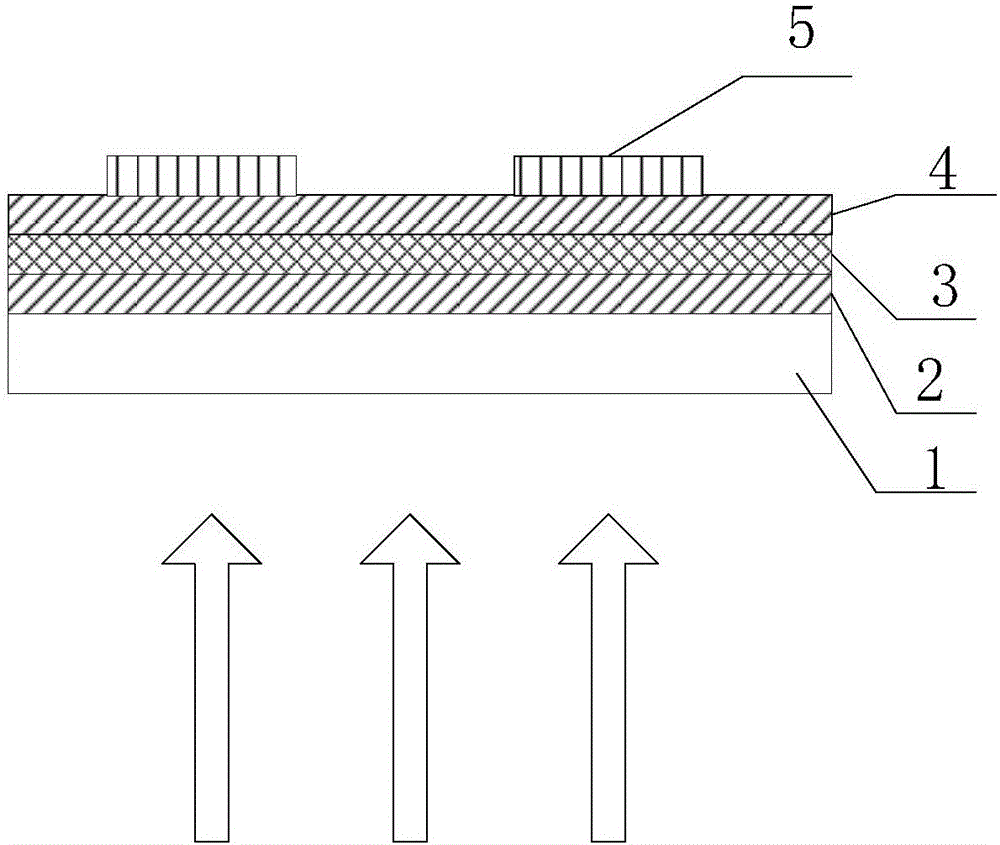

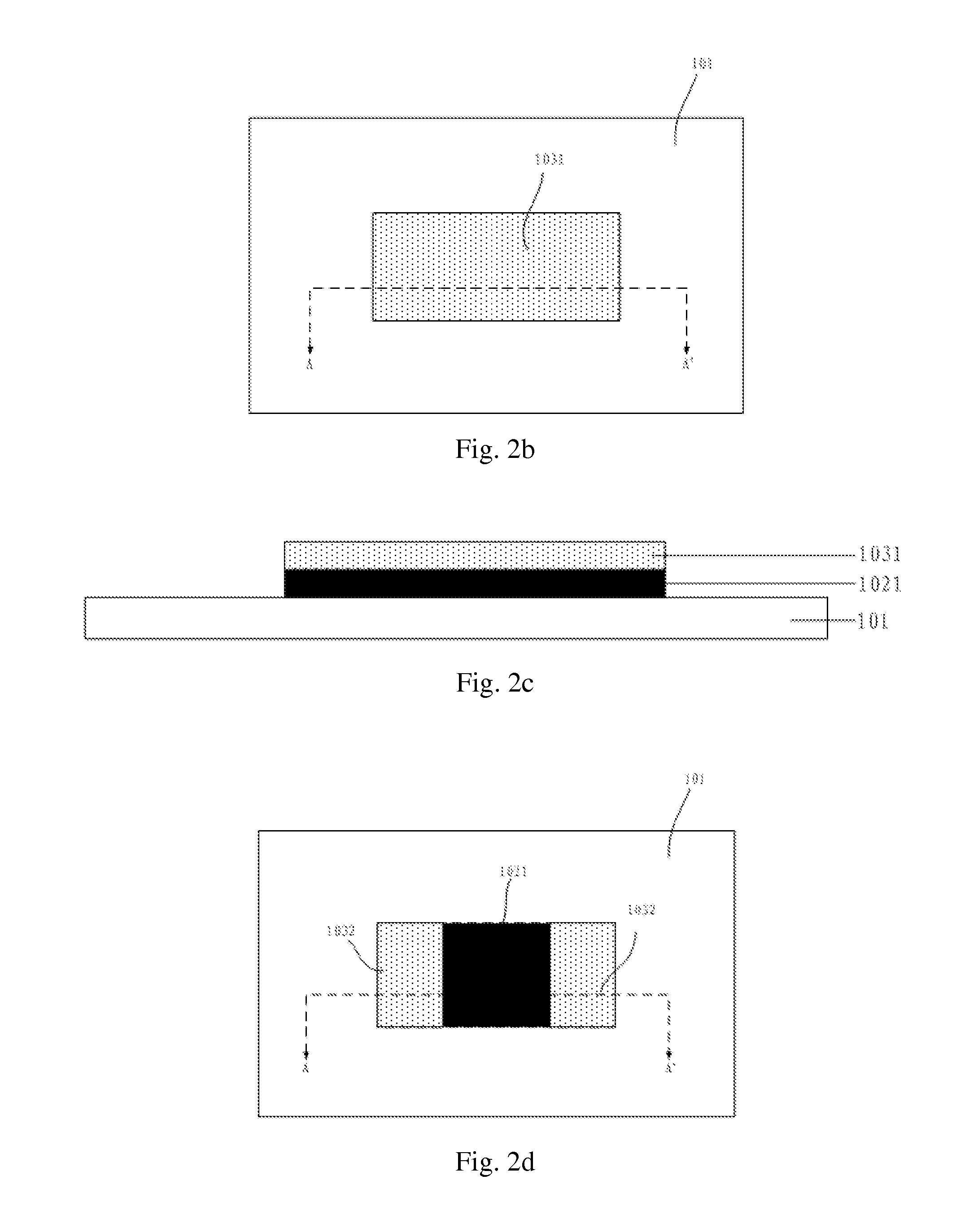

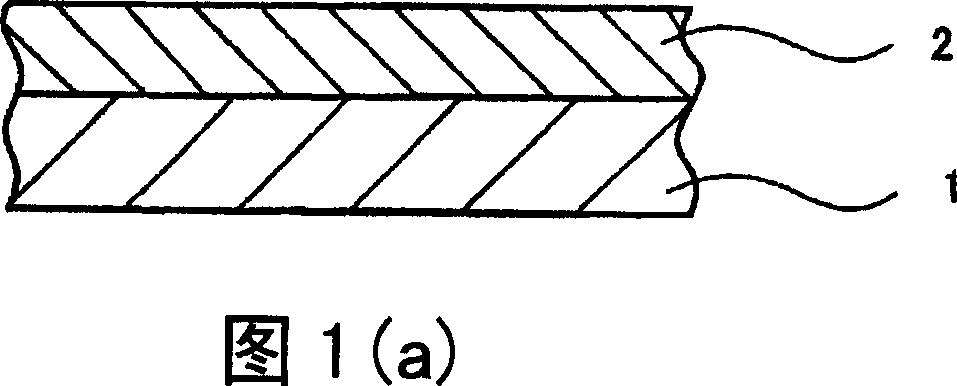

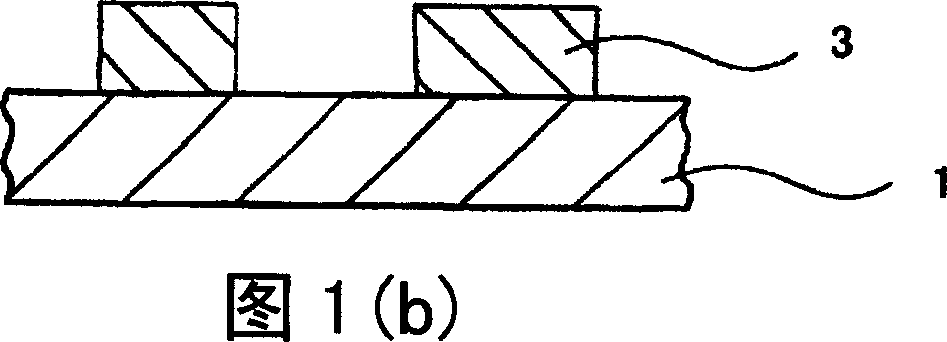

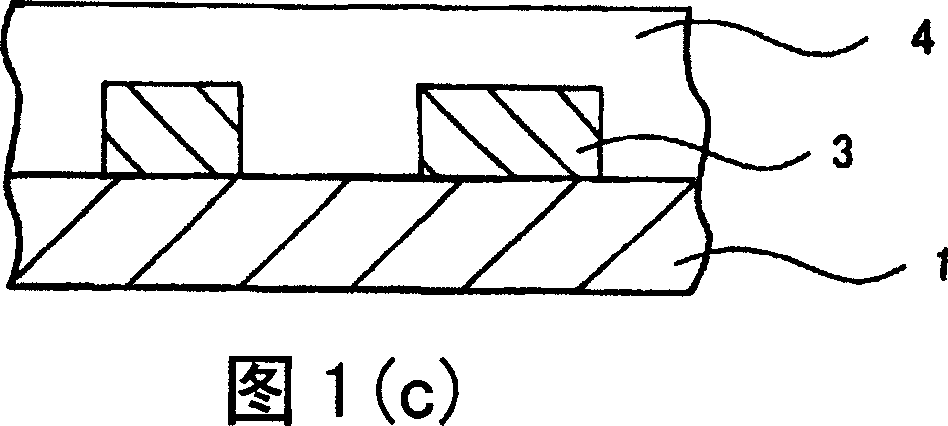

Flexible substrate, preparation method thereof, and display device

InactiveCN105118837APrevent heat carbonizationPerformance impactSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceCarbonization

The invention provides a flexible substrate, a preparation method thereof, a flexible display device, a preparation method thereof, a display substrate, and a display device in order to solve a problem that in a flexible device manufacture process in the prior art, laser energy has an adverse effect on the polycrystalline silicon active layer of a thin-film transistor and is liable to cause flexible layer carbonization in a flexible display device stripping process. The flexible substrate comprises an ultraviolet light absorption layer arranged between two flexible layers. When the active layer converts amorphous silicon into polycrystalline silicon by means of excimer laser irradiation, the flexible substrate with the sandwiched ultraviolet light absorption layer may absorb redundant laser energy by means of the ultraviolet light absorption layer in order to prevent the flexible layers from being heated and carbonized. When the flexible substrate and a glass substrate are separated, a stripping laser beam is injected from the glass substrate and the flexible substrate may absorb redundant laser energy by means of the ultraviolet light absorption layer in order to prevent the laser beam from having an adverse effect on the performance of the active layer.

Owner:BOE TECH GRP CO LTD

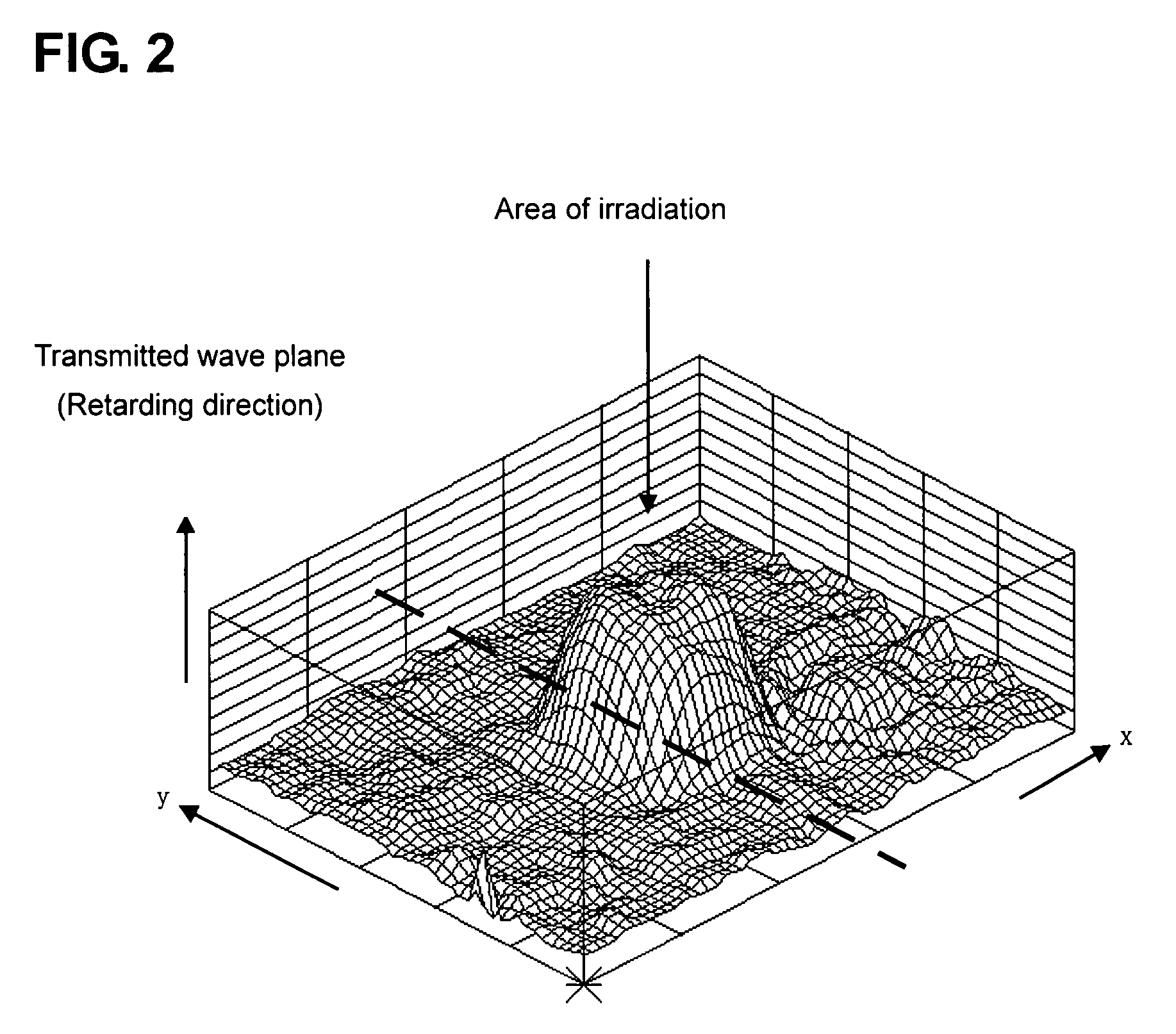

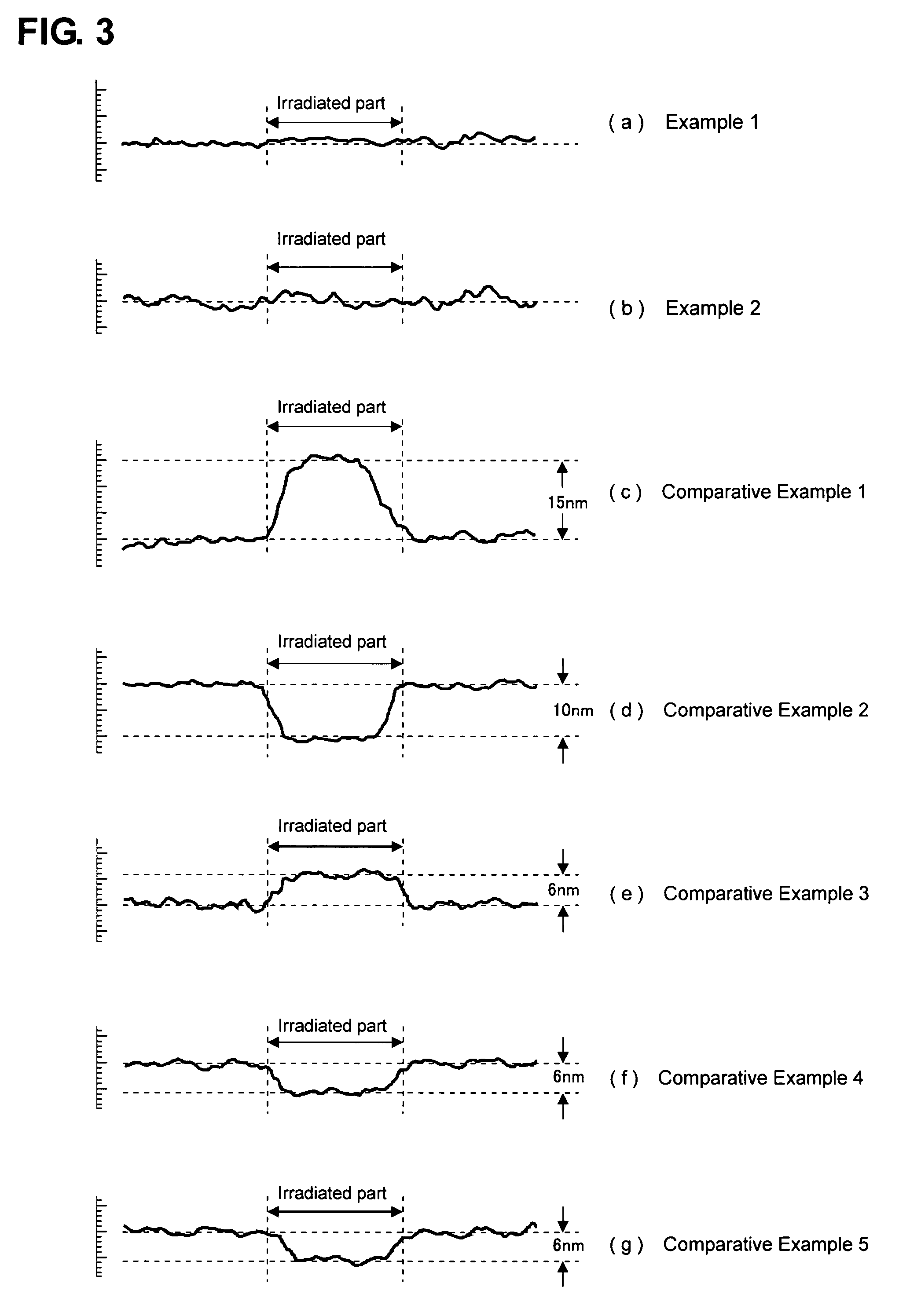

Optical synthetic quartz glass and method for producing the same

ActiveUS7312170B2Increase resistanceHigh bond energyGlass shaping apparatusOptical light guidesHydrogenHydrolysis

The present invention provides an optical synthetic quartz glass material which substantially does not cause changes in transmitted wave surface (TWS) by solarization, compaction (TWS delayed), rarefaction (TWS progressed) and photorefractive effect when ArF excimer laser irradiation is applied at a low energy density, e.g. at energy density per pulse of 0.3 mJ / cm2 or less. The present invention further provides a method for manufacturing the same. In order to solve the above-mentioned problems, the optical synthetic quartz glass material of the present invention is characterized in that, in a synthetic quartz glass prepared by a flame hydrolysis method using a silicon compound as a material, the followings are satisfied that the amount of SiOH is within a range of more than 10 ppm by weight to 400 ppm by weight, content of fluorine is 30 to 1000 ppm by weight, content of hydrogen is 0.1×1017 to 10×1017 molecules / cm3 and, when the amounts of SiOH and fluorine are A and B, respectively, total amount of A and B is 100 ppm by weight or more and B / A is 0.25 to 25.

Owner:HERAEUS QUARZGLAS +1

Water soluble resin composition and method for pattern formation using the same

InactiveUS7745093B2Efficient preparationGood paintabilityPhotosensitive materialsRadiation applicationsResistHigh density

In the present invention, in a water soluble resin composition for use in a method for pattern formation in which a covering layer is provided on a resist pattern formed of a radiation-sensitive resin composition capable of coping with ArF exposure to increase the width of the resist pattern and thus to realize effective formation of higher density trench or hole pattern, the size reduction level of the resist pattern layer can be further increased as compared with that in the prior art technique, and, in addition, the size reduction level dependency of the coarse-and-fine resist pattern can be reduced. A method for pattern formation using the water soluble resin composition is also provided. The water soluble resin composition which is usable for the method for pattern formation applicable to ArF excimer laser irradiation comprises a water soluble resin, an acid generating agent capable of generating an acid upon heating, a surfactant, a crosslinking agent, and a water-containing solvent.

Owner:MERCK PATENT GMBH

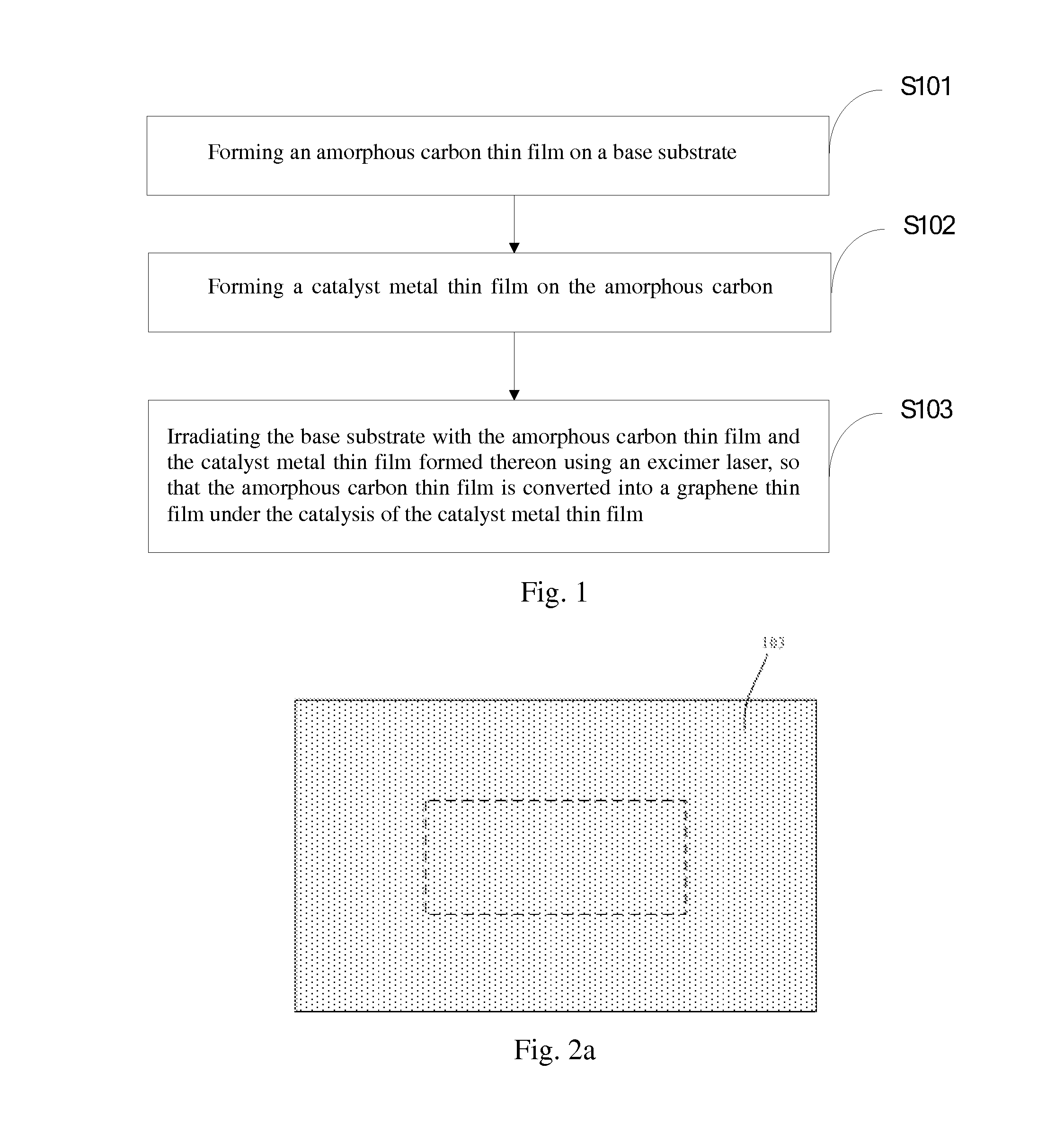

Method for preparing graphene, thin-film transistor, array substrate, and display panel

InactiveUS20150270406A1Thin surfaceAvoid contaminationTransistorSolid-state devicesOptoelectronicsCvd graphene

This present invention discloses a method for preparing graphene, a thin-film transistor, an array substrate, and a display panel. Above all, an amorphous carbon thin film and a catalyst metal thin film are formed on a base substrate in this order. Then, the catalyst metal thin film and the amorphous carbon thin film are allowed to form a eutectic at a high temperature caused by an excimer laser in a manner of excimer laser irradiation. When the irradiation is finished, the surface temperature of the catalyst metal thin film is drastically decreased, allowing most of carbon atoms of the amorphous carbon thin film to be locked in the catalyst metal thin film and only a small amount of carbon atoms to be precipitated on the lower surface of the catalyst metal thin film, so that a graphene thin film is formed. Since the above described the method employs excimer laser irradiation to grow a graphene thin film, and the excimer laser has minor effect on other film layers located under the graphene thin film, graphene can be formed on the base substrate without a transfer process. Therefore, damage and contamination of graphene thin film caused by the transfer process are prevented and properties of graphene thin film are ensured.

Owner:BOE TECH GRP CO LTD

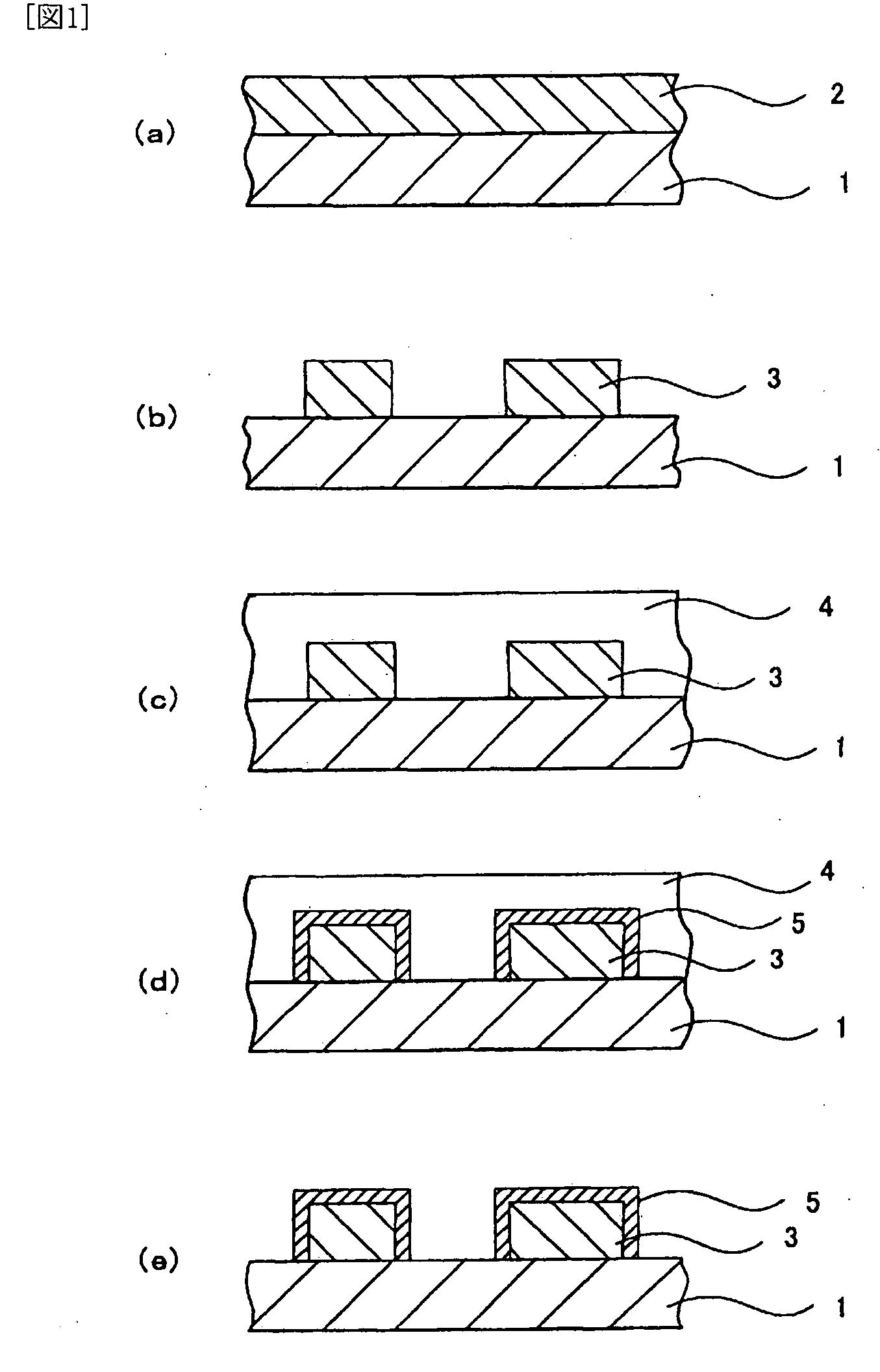

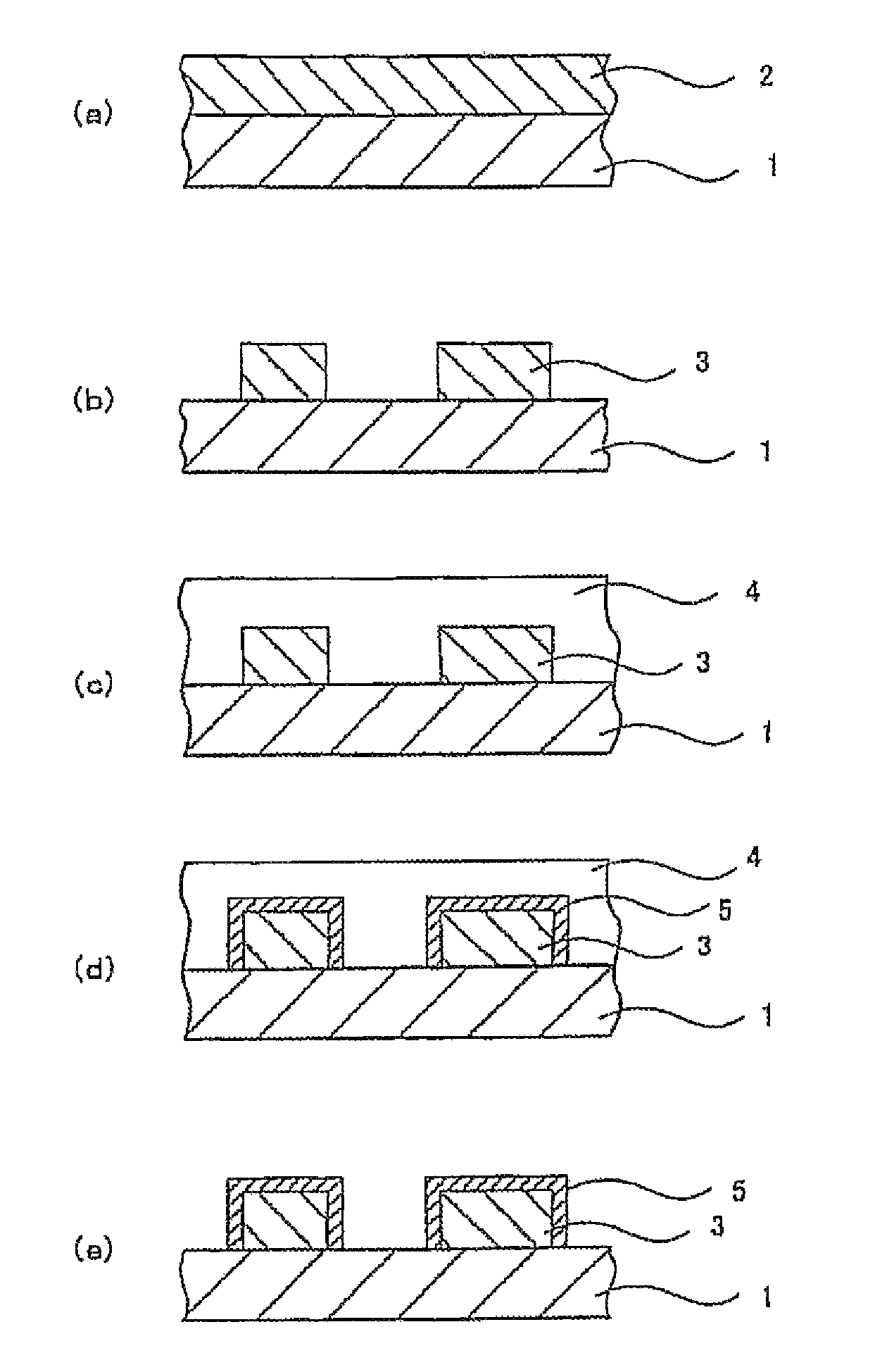

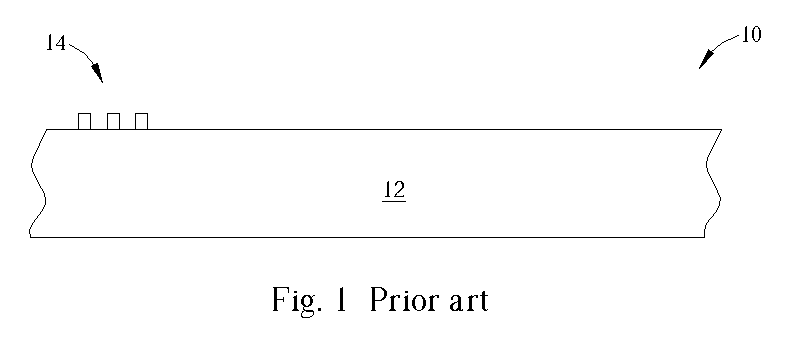

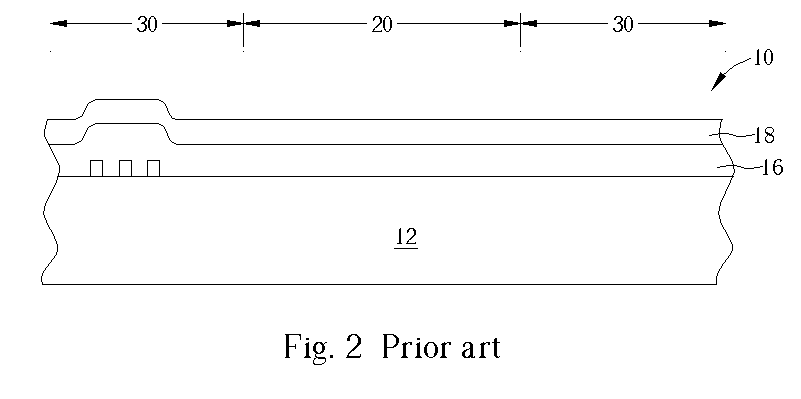

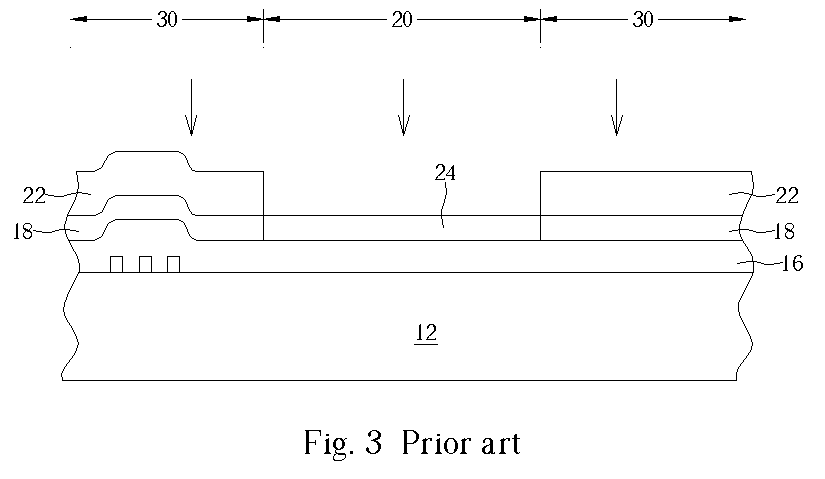

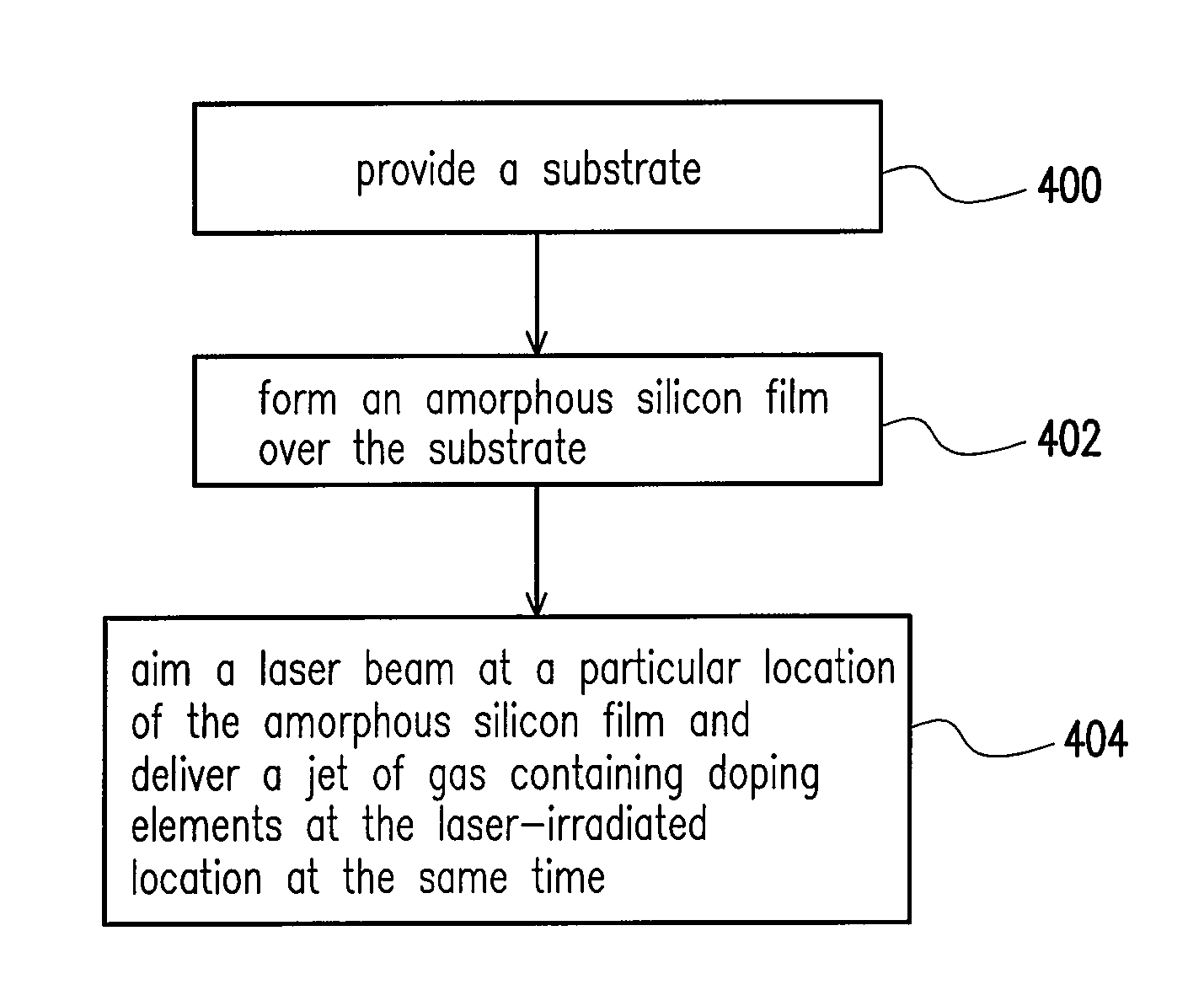

Method of fabricating polysilicon film by excimer laser crystallization process

ActiveUS6964831B2Simplify the manufacturing processLow costTransistorRadiation applicationsOptoelectronicsCrystallization

A method of fabricating a polysilicon film by an excimer laser crystallization process is disclosed. First, a substrate with a first region, a second region surrounding the first region, and a third region is provided. An amorphous silicon film is formed on the substrate. A photo-etching process is performed to remove parts of amorphous silicon film in the third region to form an alignment mark. Then, a mask layer is formed on the amorphous silicon film and a second photo-etching process is performed to remove the mask layer in the first region to expose the amorphous silicon film in the first region. After that, an excimer laser irradiation process is performed so that the amorphous silicon film in the first region is crystallized and becomes a polysilicon film.

Owner:CHINA STAR OPTOELECTRONICS INT HK

Method of improving the properties of adhesion of a non-oxide ceramic substrate before gluing it

Owner:ALSTOM TRANSPORT TECH SAS

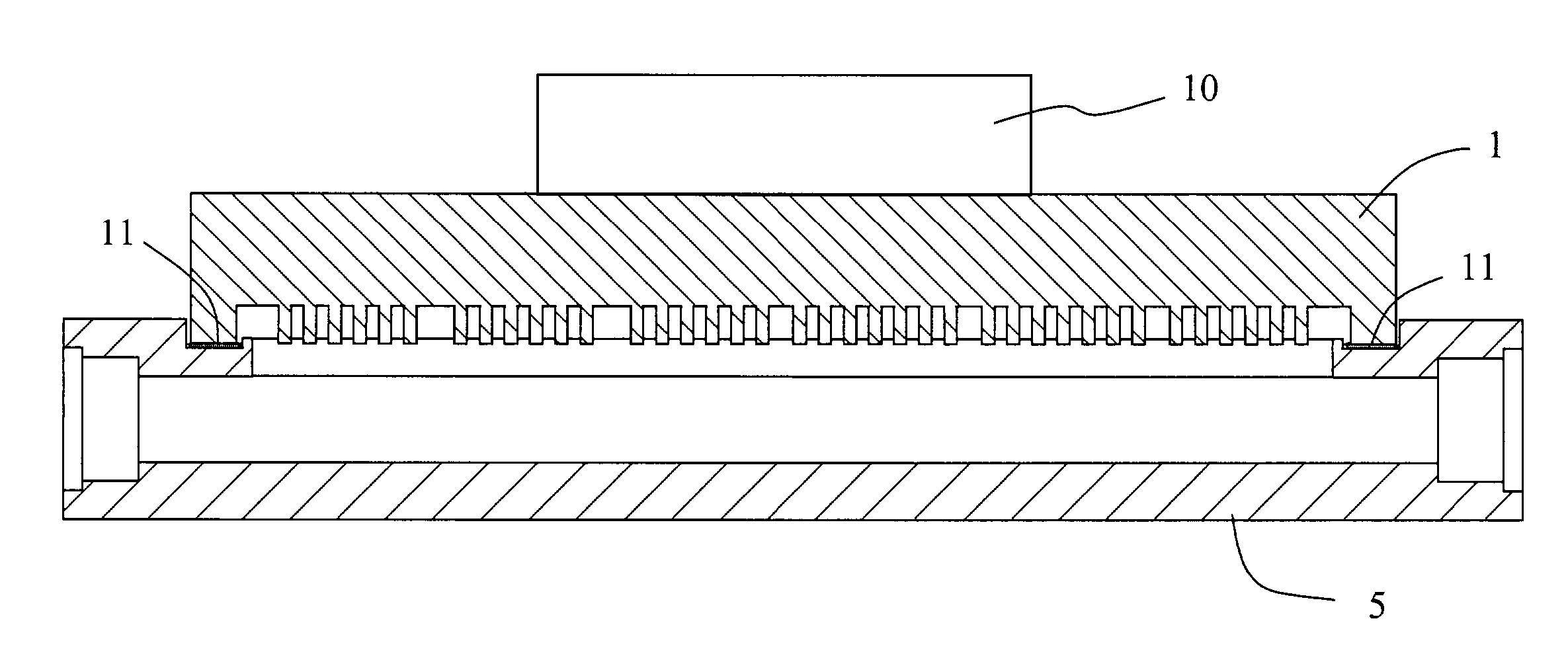

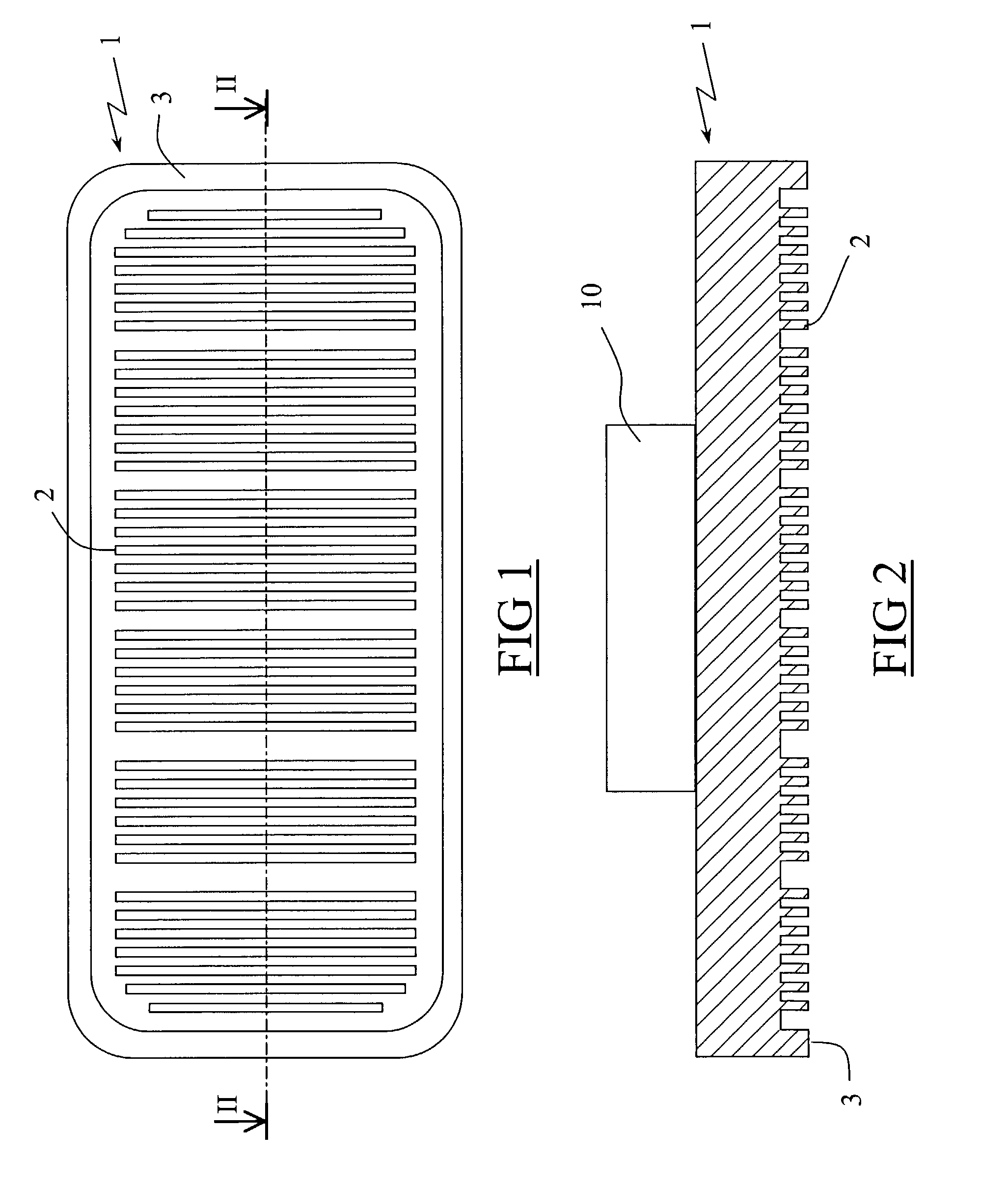

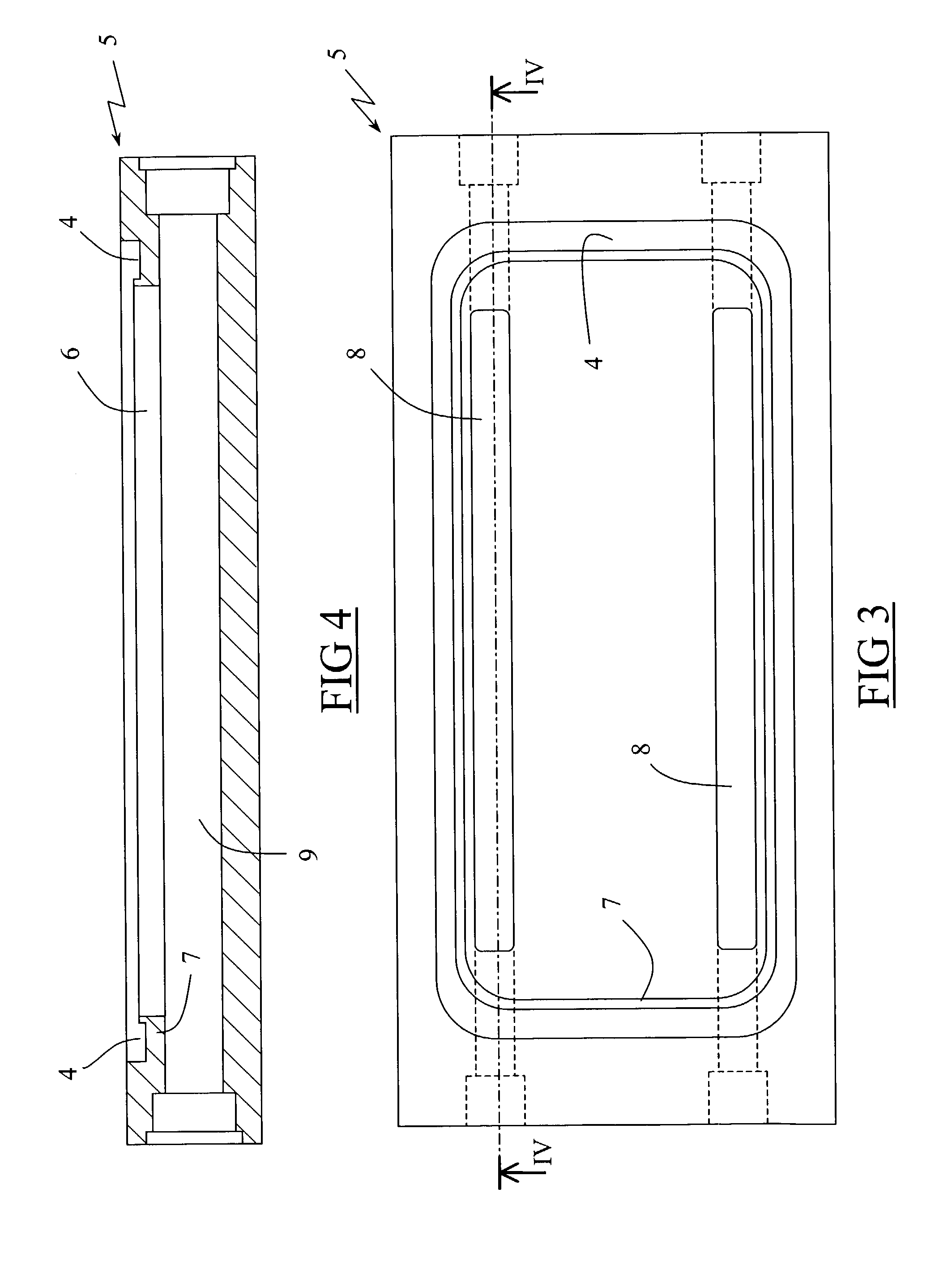

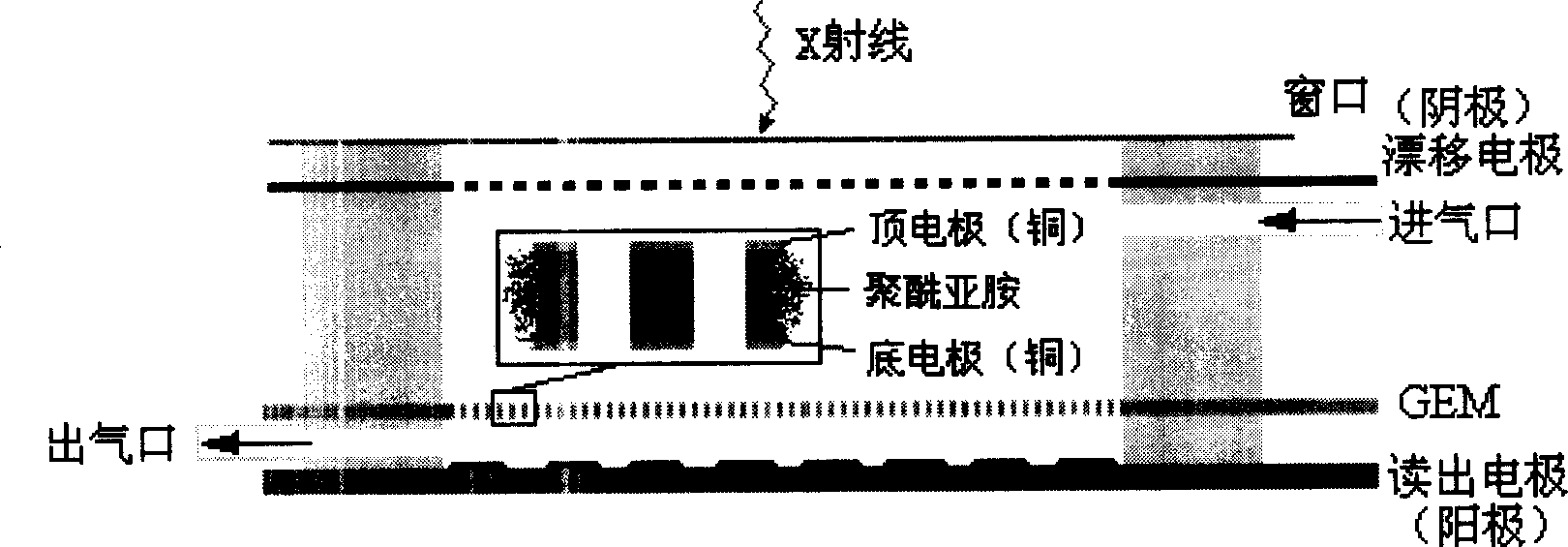

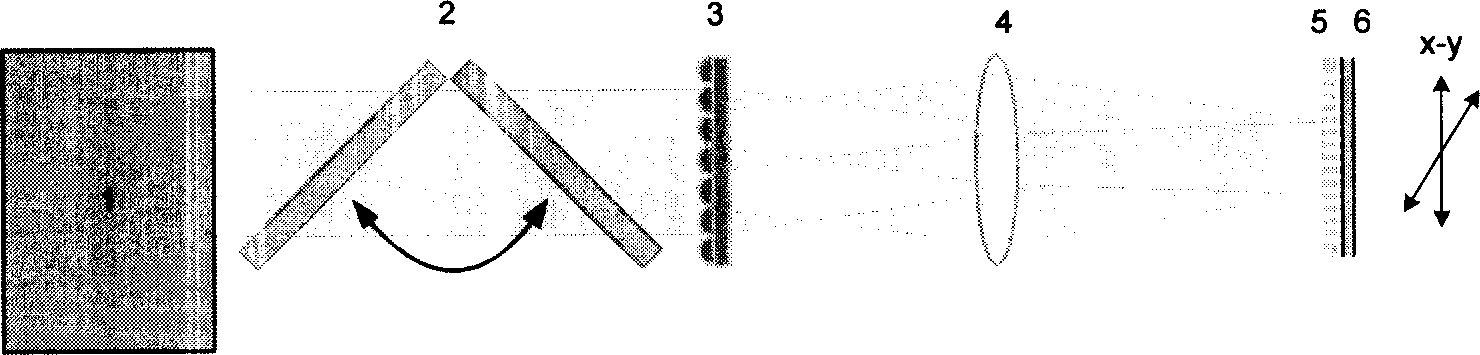

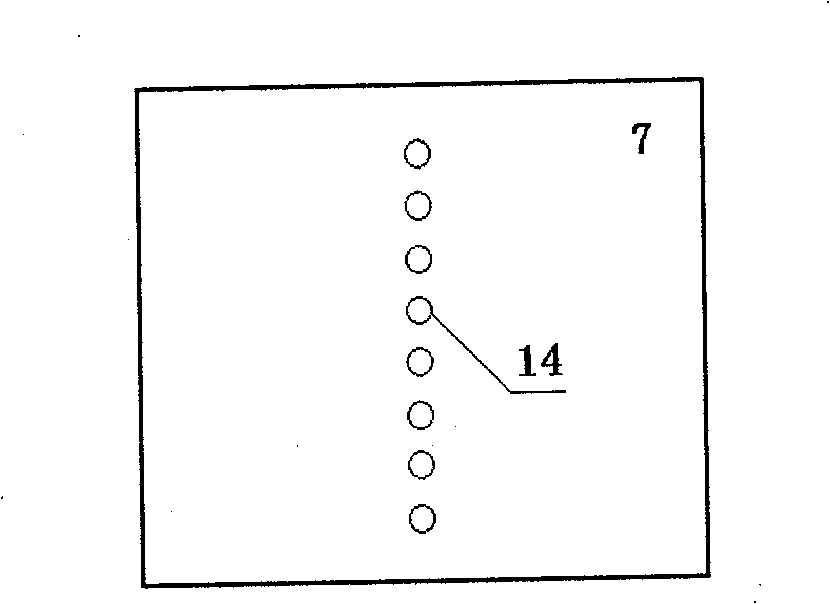

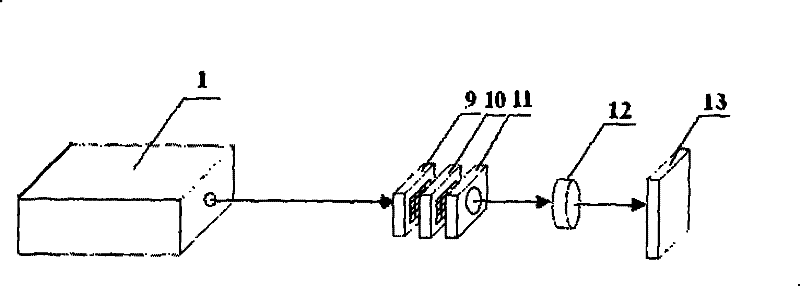

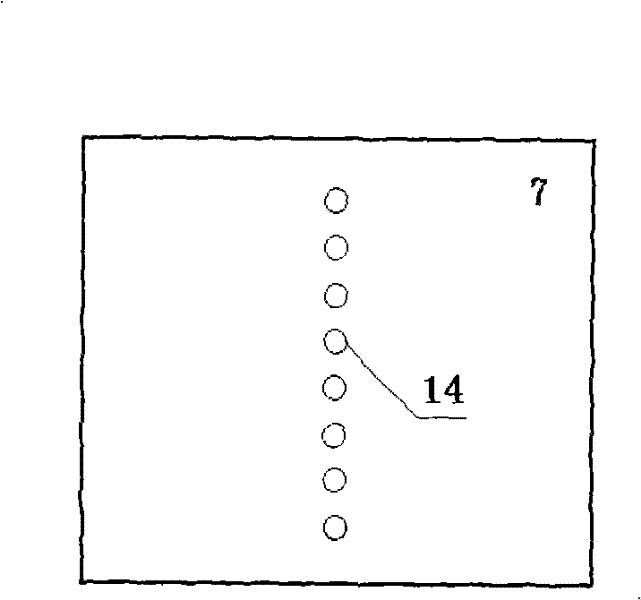

Method for making gas electron multiplier polymer film grid

The invention is a manufacturing method for gas electron multiplier polymers film mesh applied to the X ray detection. The invention uses 308nm norm molecular laser to irradiate the polyimide (PI) coated with red copper film at the two surfaces, the micro-aperture mesh are formed on the PI film by using the effect of the micro-aperture array mask board attached on the PI film. The mesh with any size can be acquired with X-Y scanning platform. The invention produces the gas electron multiplier polymer film mesh can be acquired by using 308nm norm molecular laser poring method. It is simple and effective.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Phase shift mask blank, phase shift mask, and method for manufacturing the same

InactiveUS6677087B2Semiconductor/solid-state device manufacturingGlass/slag layered productsNitrogenSurface roughness

An object of the present invention is to provide a half-tone phase shift mask blank and a half-tone phase shift mask of which a translucent film has improved acid resistance, alkali resistance and resistance to excimer laser irradiation while maintaining the internal stress of the film within an acceptable range for the intended use. To achieve the aforementioned object, the present invention provides a half-tone phase shift mask blank which comprises a transparent substrate having provided thereon a translucent film comprising at least one thin layer containing silicon and at least one of nitrogen and oxygen and which is to be exposed to light whose center wavelength is 248 nm or shorter, wherein said translucent film is dense such that it has a center-line surface roughness (Ra) of 0.3 nm or smaller.

Owner:HOYA CORP

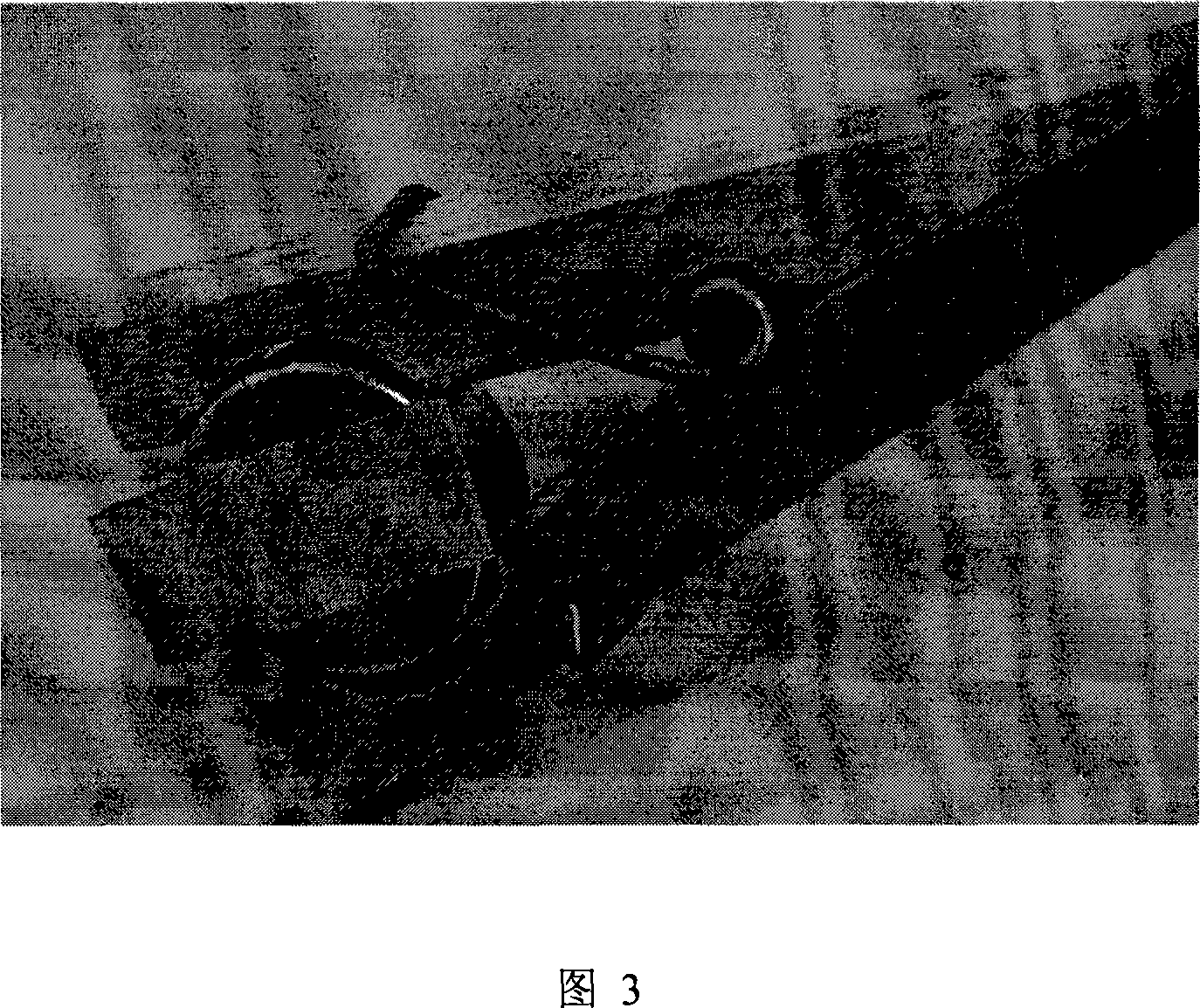

Method for preparing magnetic function textile by utilizing quasi-molecule ultraviolet source

The invention relates to a method for utilizing excimer laser irradiation to prepare magnetic functional textile, which comprises: adopting a coprecipitation method to prepare nanometer ferroferric oxide granules, then, using oleic acid to modify the surface of the nanometer ferroferric oxide granules, then, dipping polyester fabrics in ethanol solution which contains the nanometer ferroferric oxide granules whose surface is modified by the oleic acid, lastly, utilizing excimer laser irradiation 222nm to irradiate two surfaces of the polyester fabrics after dipping, and finally obtaining the magnetic functional textile with comparatively high fastness to washing. The magnetic functional textile which is prepared by the method has good washability, the method of the invention is simple and novel and has simple technique, few equipment, small strength damage to the polyester fabrics, low energy consumption, convenient extension and the like.

Owner:DONGHUA UNIV

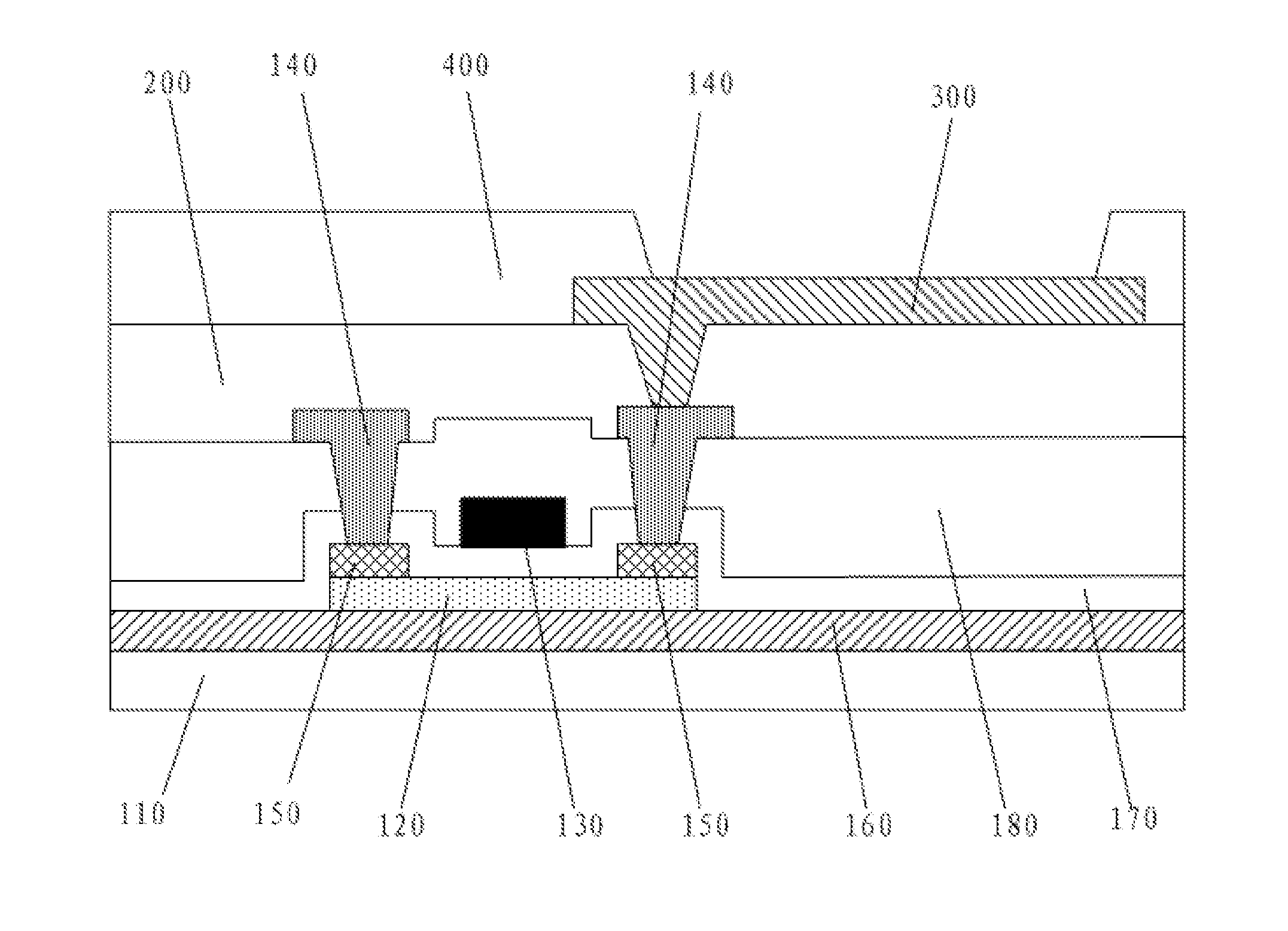

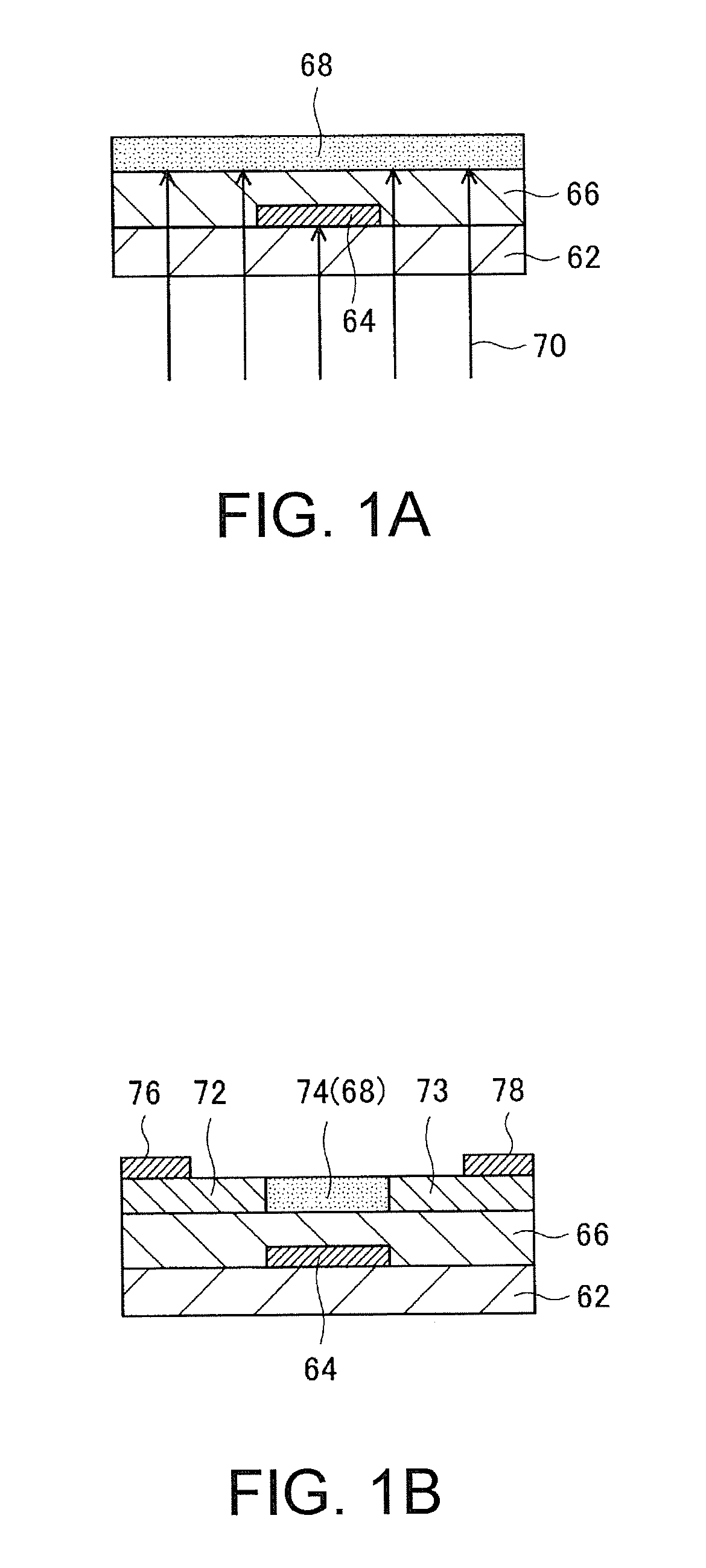

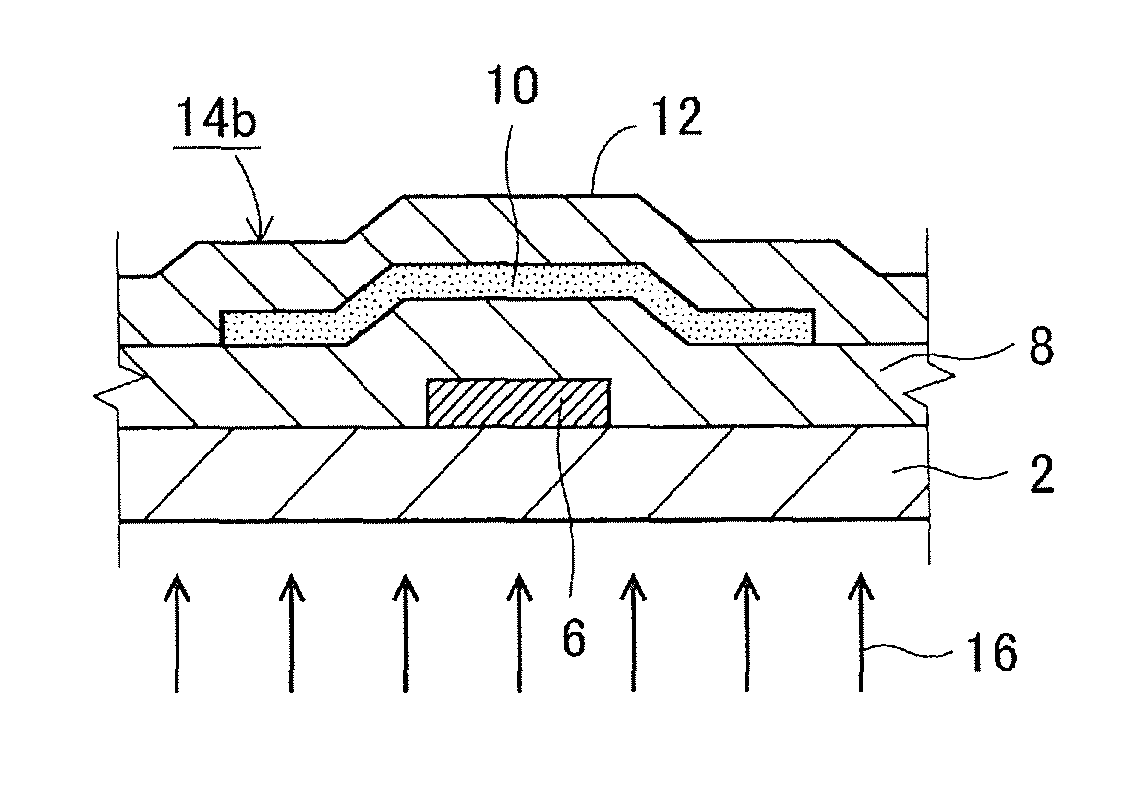

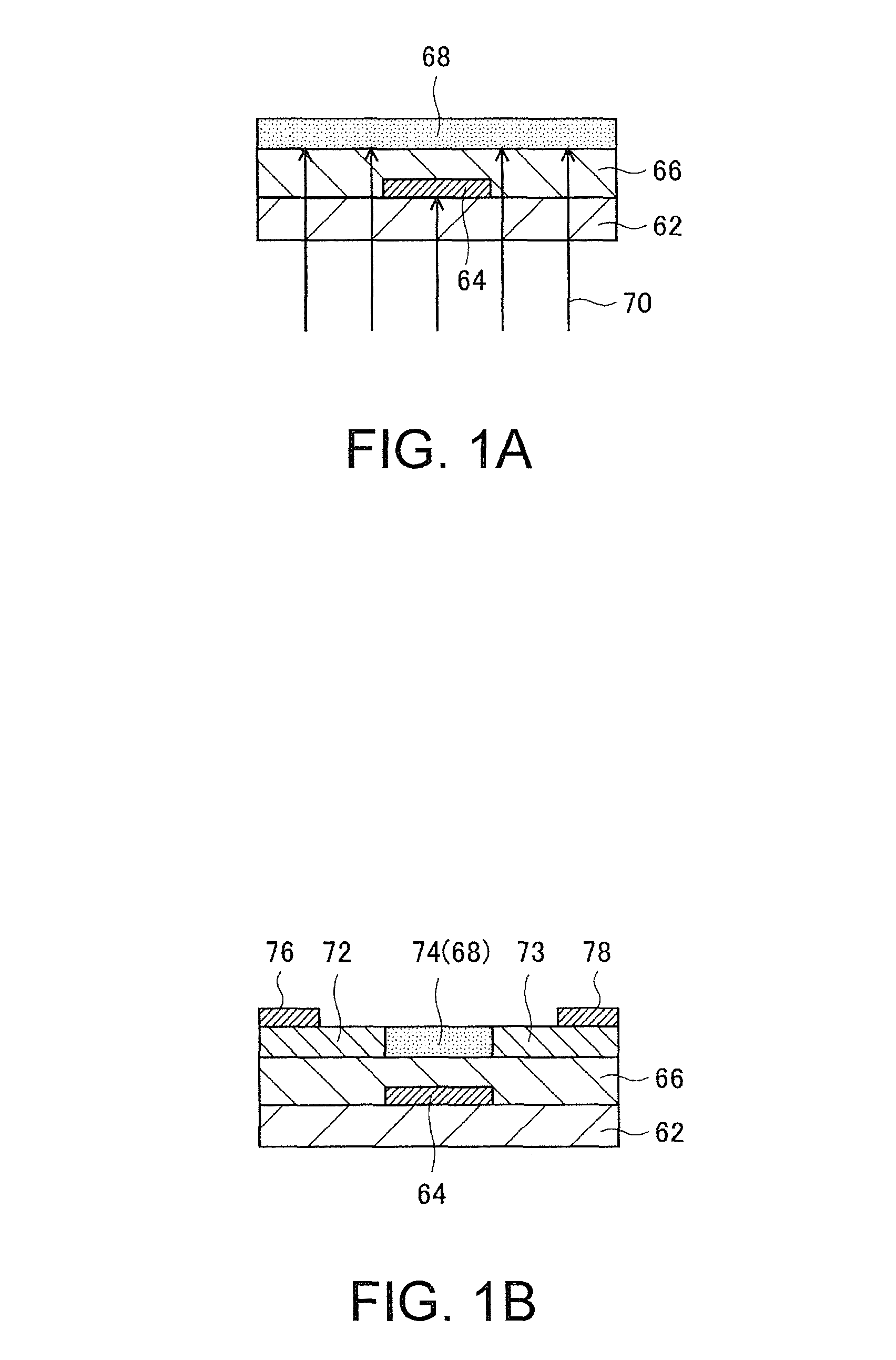

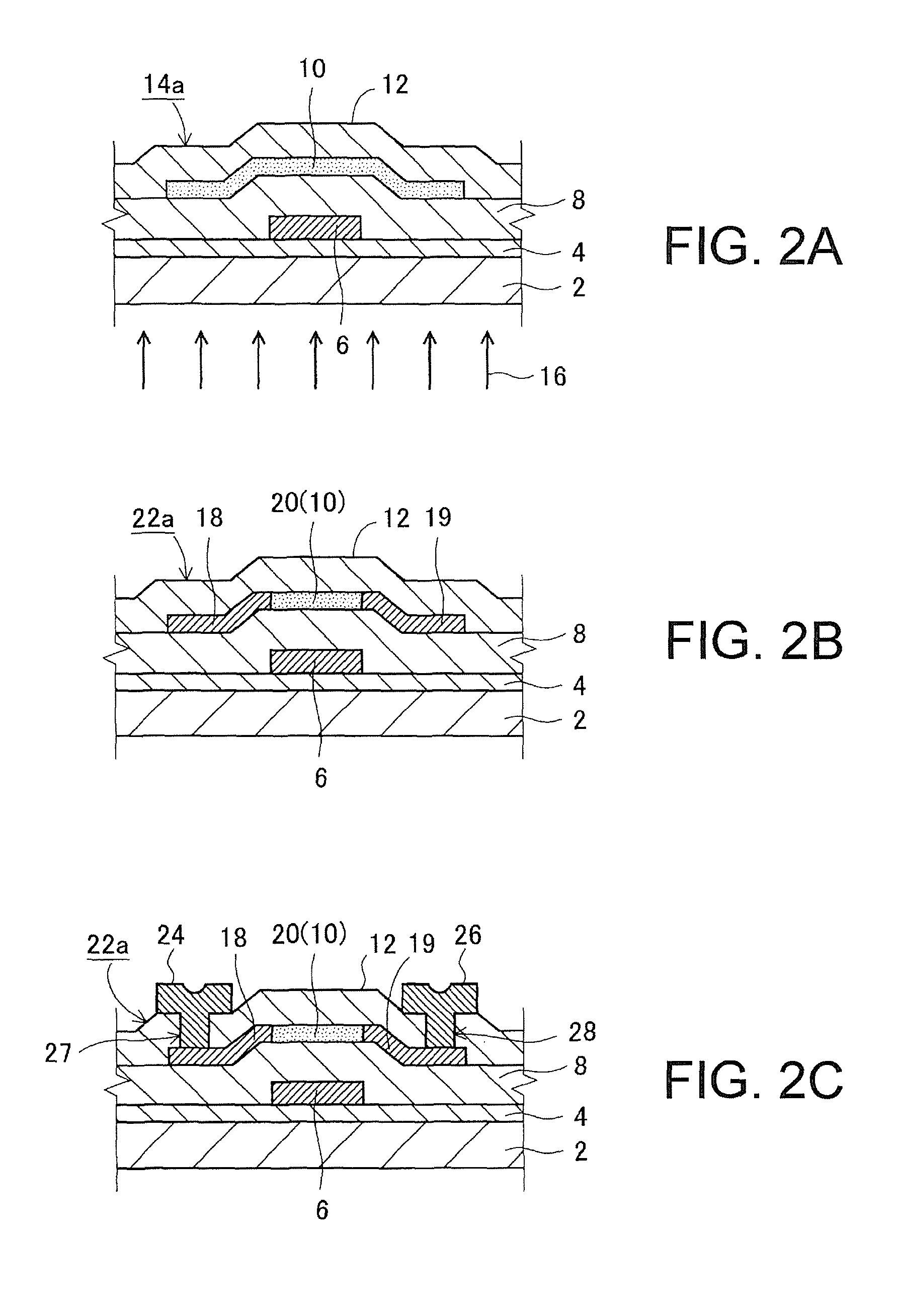

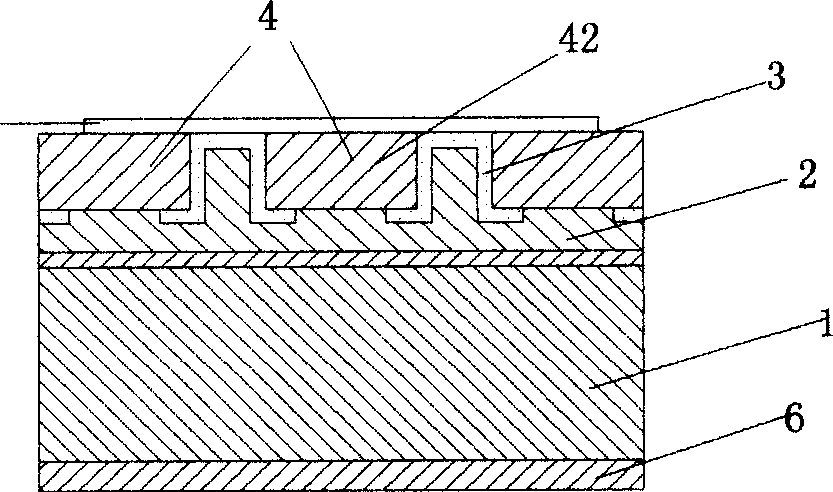

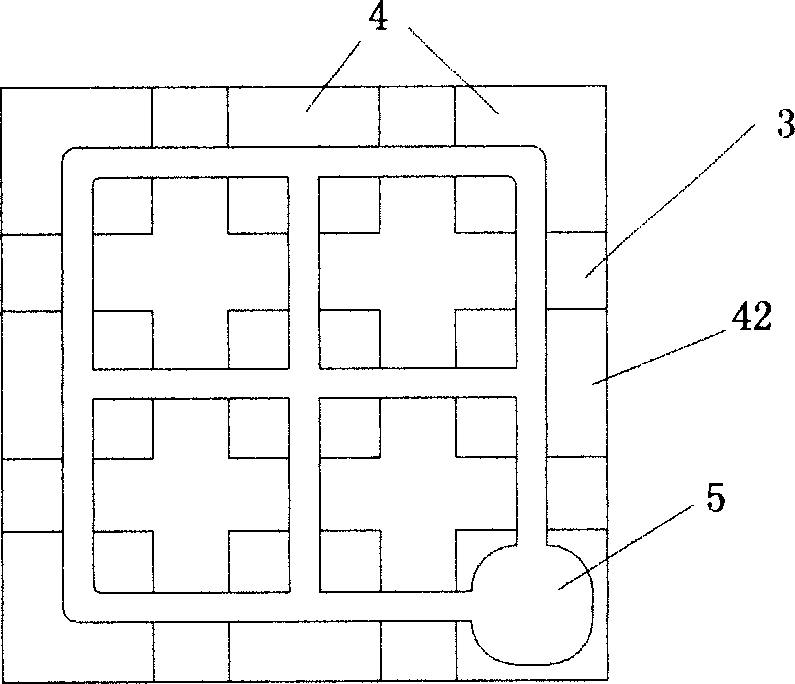

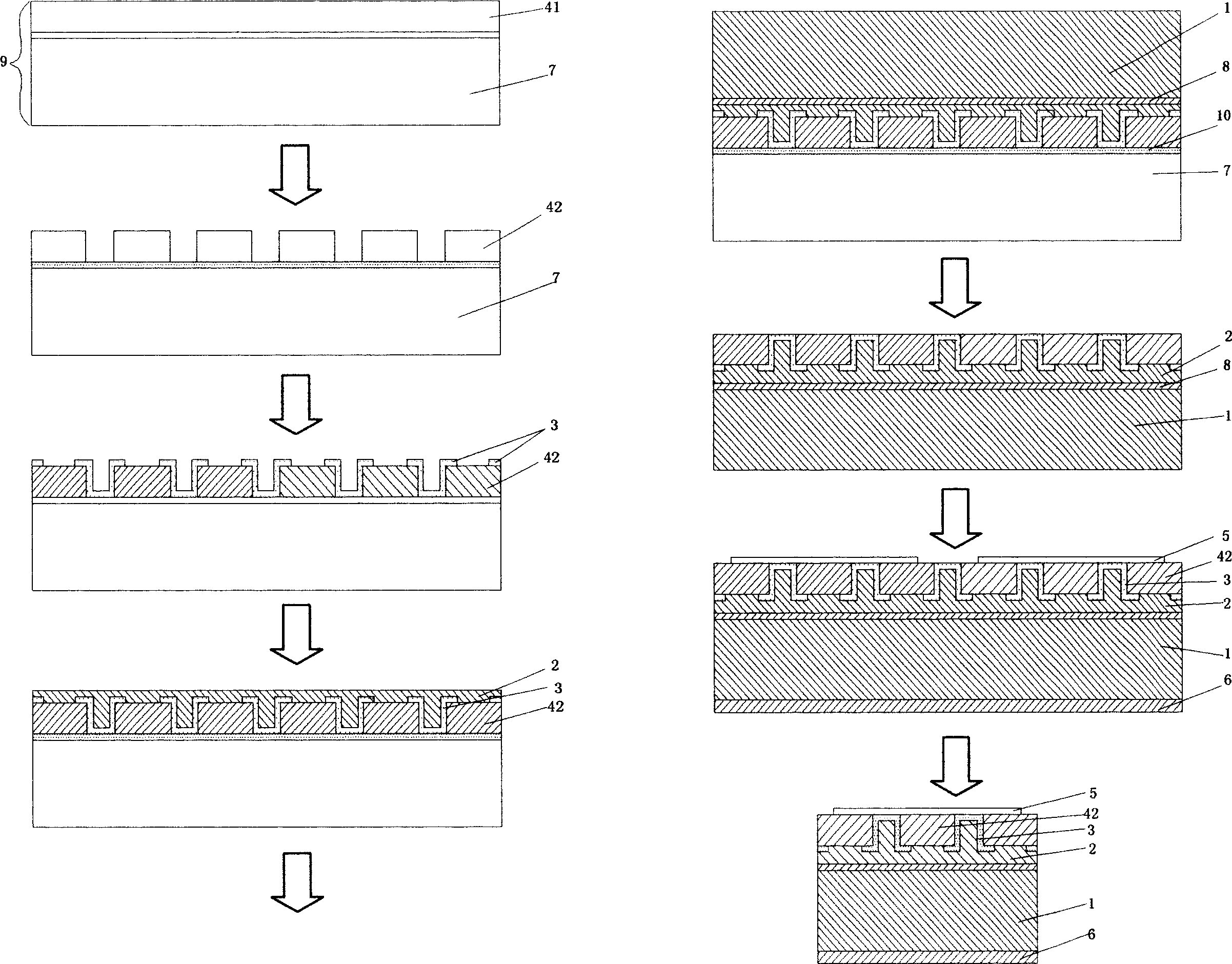

Method for fabricating thin-film transistor

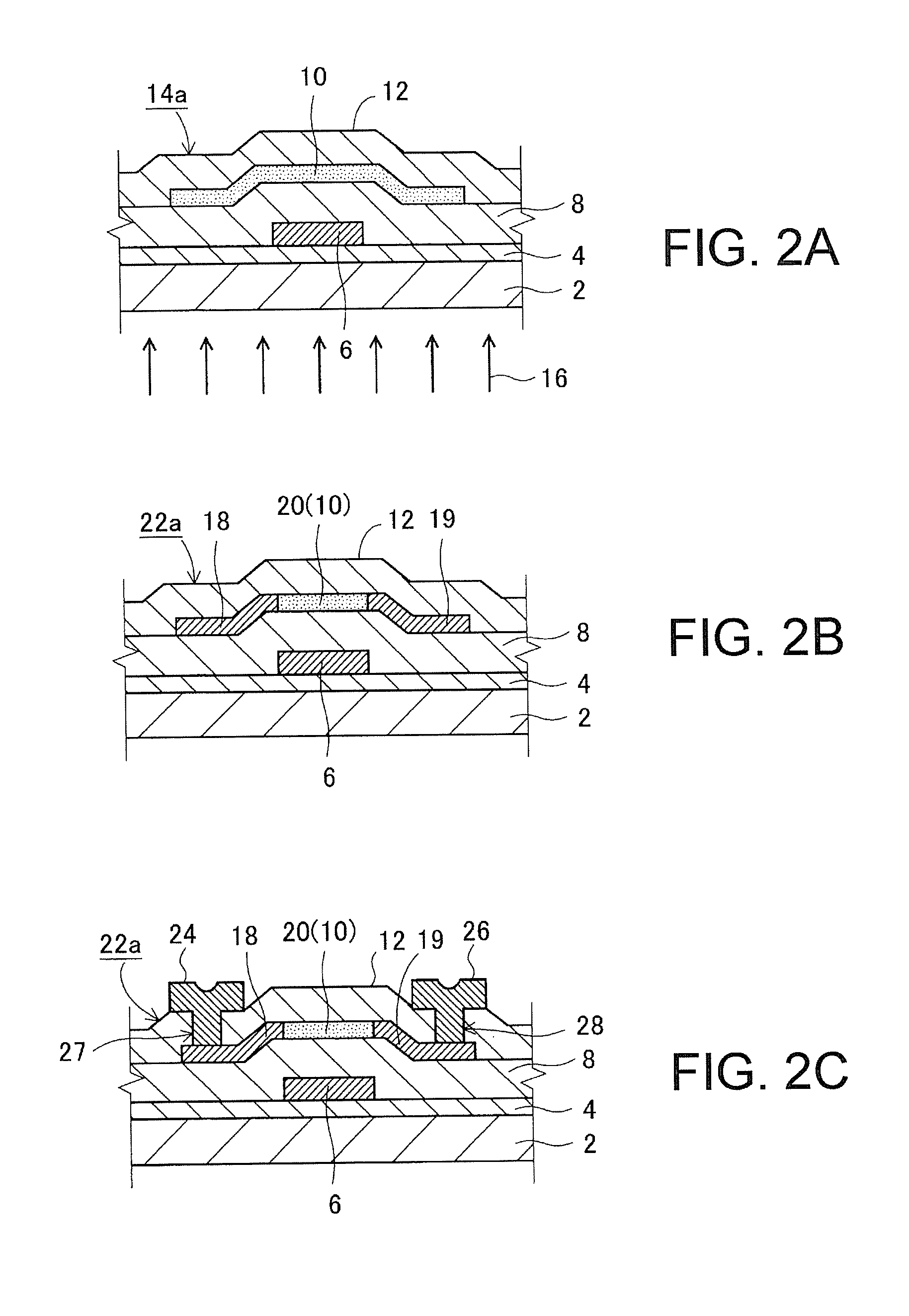

ActiveUS20150017761A1Film property deteriorateDecreasing density of filmSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorOxide semiconductor

A method for fabricating a thin-film transistor is described. A structure is provided, including a substrate transmitting an excimer laser light, a diffusion prevention film on the substrate, a gate electrode and a gate insulating film on the diffusion prevention film, and an oxide semiconductor layer on the gate insulating film. The structure is irradiated with an excimer laser light from the side of the substrate, so that two outer regions of the oxide semiconductor layer beside the region corresponding to the gate electrode are irradiated by the excimer laser light, with the gate electrode as a mask, to be reduced in resistance and thereby one of the two outer regions forms a source region and the other one forms a drain region. The diffusion prevention film includes a SiN:F film containing fluorine in a SiN film.

Owner:NISSIN ELECTRIC CO LTD

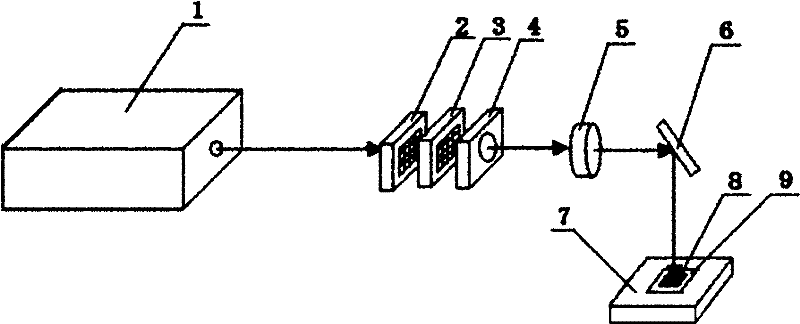

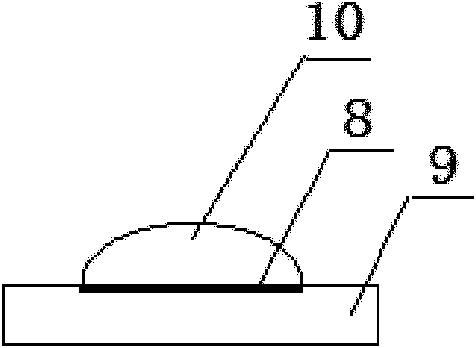

Quasi-molecule ultraviolet source treatment method and device for textile surface modifying

InactiveCN101235589ASurface modification treatment is efficientGood surface modificationPhysical treatmentAnimal fibresBreaking strengthUltraviolet

The invention relates to a method for processing excimer laser irradiation, which is used for modifying textile surface, which comprises following steps: firstly, placing an object which will be processed, secondly, regulating the distance between the excimer laser irradiation and textile, thirdly, regulating the pressure strength in an excimer laser irradiation processing chamber, fourthly, processing by irradiating, and irradiating the object which will be processed for 0.1-0.5min. The method of the invention for modifying the surface of the textile is highly effective and convenient. The hydrophilicity of the textile surface which is modified is greatly increased, the appearance dying depth is also improved, and the influence for warp and weft breaking strength is not big.

Owner:DONGHUA UNIV

Low-resistance n type semiconductor diamond and process for producing the same

InactiveCN1692186ASolving problems that arise in adulterated situationsGood crystal propertiesPolycrystalline material growthSemiconductor/solid-state device manufacturingSource materialLow resistance

Concerns lithium-doped diamond: Low-resistivity n-type semiconductor diamond doped with lithium and nitrogen, and a method of manufacturing such diamond are provided. Low-resistivity n-type semiconductor diamond containing 1017 cm-3 or more of lithium atoms and nitrogen atoms together, in which are respectively doped lithium atoms into carbon-atom interstitial lattice sites, and nitrogen atoms into carbon-atom substitutional sites, with the lithium and the nitrogen holding arrangements that neighbor each other. To obtain low-resistivity n-type semiconductor diamond, in a method for the vapor synthesis of diamond, photodissociating source materials by photoexcitation utilizing vacuum ultraviolet light and irradiating a lithium source material with an excimer laser to scatter and supply lithium atoms enables the diamond to be produced.

Owner:SUMITOMO ELECTRIC IND LTD

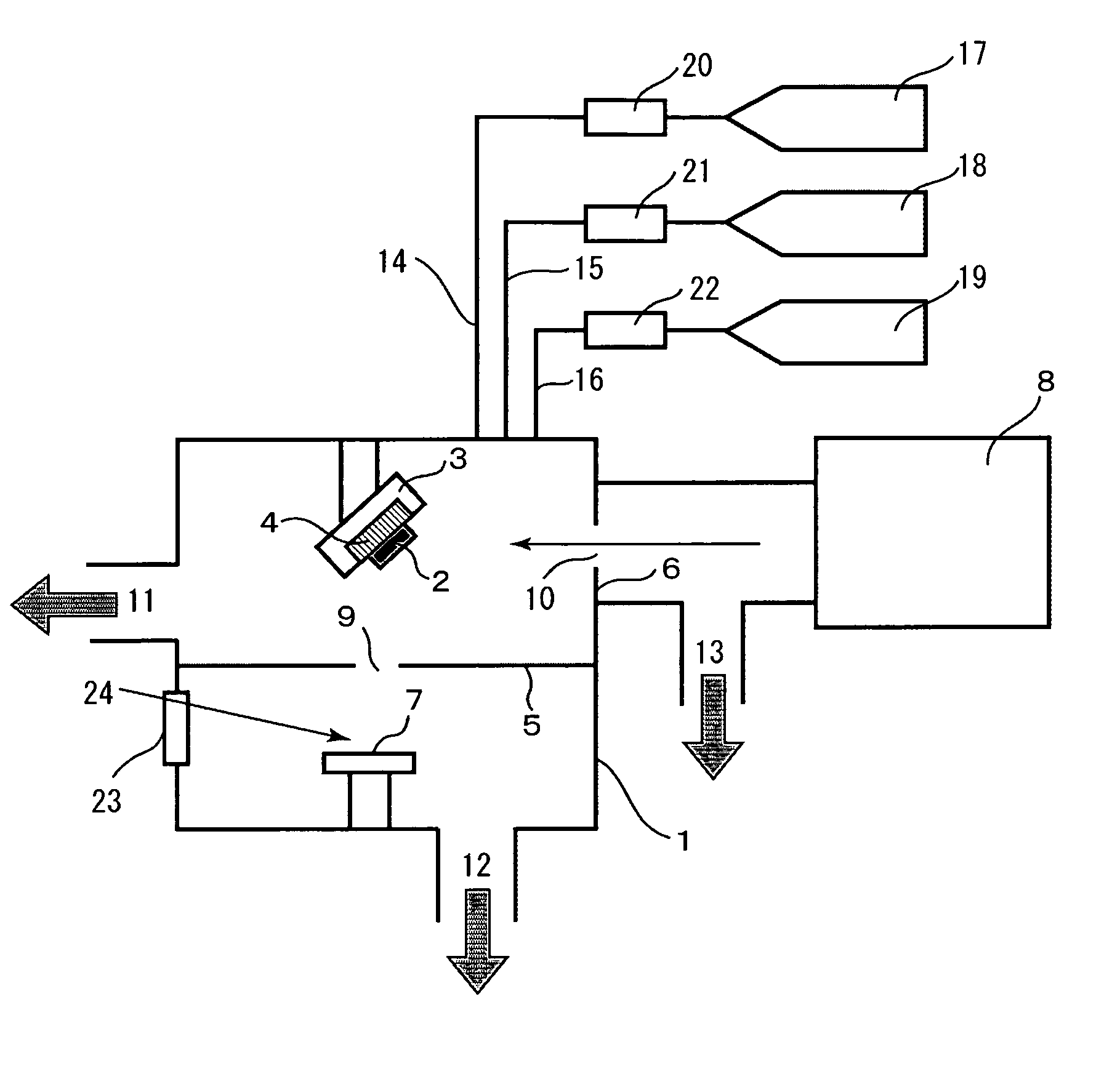

Method of forming polysilicon film using a laser annealing apparatus

InactiveUS20070054478A1Minimize changesImprove accuracySemiconductor/solid-state device manufacturingChemical vapor deposition coatingOptoelectronicsLaser beams

An excimer laser annealing apparatus and the application of the same for stabilizing the atmosphere surrounding an area irradiated by an excimer laser. The apparatus includes a chamber, a gas diversion nozzle, an excimer laser and a gas supply device. The gas diversion nozzle is positioned inside the chamber. The laser beam produced by the excimer laser passes through the gas diversion nozzle. The gas supply device connects with the gas diversion nozzle for providing a jet of gas to the laser-irradiated area and carrying away any pollutants from the irradiated area.

Owner:AU OPTRONICS CORP

Low-resistance n type semiconductor diamond and process for producing the same

InactiveUS20050217561A1Improve crystal qualityPolycrystalline material growthFrom normal temperature solutionsGas phaseSource material

Concerns lithium-doped diamond: Low-resistivity n-type semiconductor diamond doped with lithium and nitrogen, and a method of manufacturing such diamond are provided. Low-resistivity n-type semiconductor diamond containing 1017 cm−3 or more of lithium atoms and nitrogen atoms together, in which are respectively doped lithium atoms into carbon-atom interstitial lattice sites, and nitrogen atoms into carbon-atom substitutional sites, with the lithium and the nitrogen holding arrangements that neighbor each other. To obtain low-resistivity n-type semiconductor diamond, in a method for the vapor synthesis of diamond, photodissociating source materials by photoexcitation utilizing vacuum ultraviolet light and irradiating a lithium source material with an excimer laser to scatter and supply lithium atoms enables the diamond to be produced.

Owner:SUMITOMO ELECTRIC IND LTD

Method for quickly erasing and writing conductive PVDF (Polyvinylidene Fluoride) layer through water film

InactiveCN102248688ARealize fast erasing functionEasy to operatePolyvinylidene difluorideHigh pressure

The invention provides a method for quickly erasing and writing a conductive PVDF (Polyvinylidene Fluoride) layer through a water film. The method comprises the following steps of: covering the water film above a conductive layer to be erased, generating a high-temperature high-pressure environment in an active region by utilizing an excimer laser irradiation technology, and erasing the conductive layer due to the breakage of the conductive layer in a water film laser vaporization process. According to the method for quickly erasing and writing the conductive PVDF layer through the water film, disclosed by the invention, the surface of a reduced material can be quickly modified again through laser irradiation, thus the material is recycled.

Owner:BEIJING UNIV OF TECH

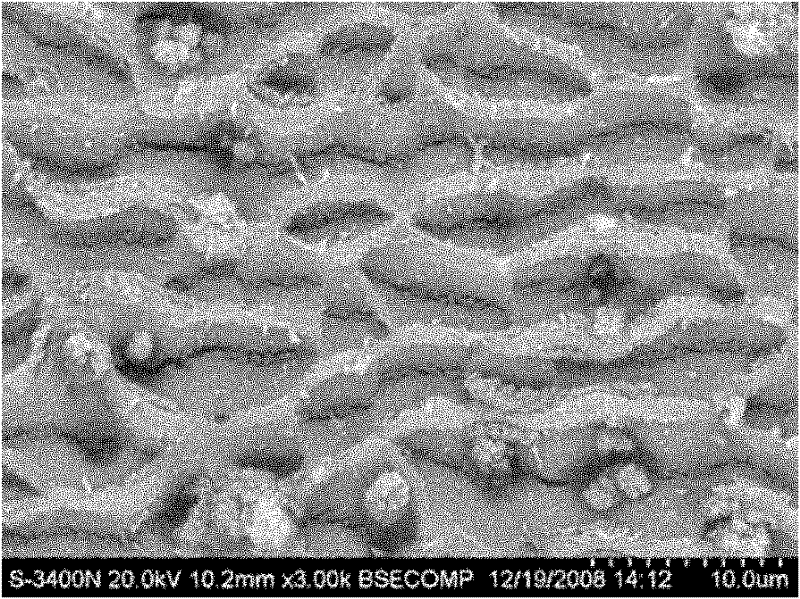

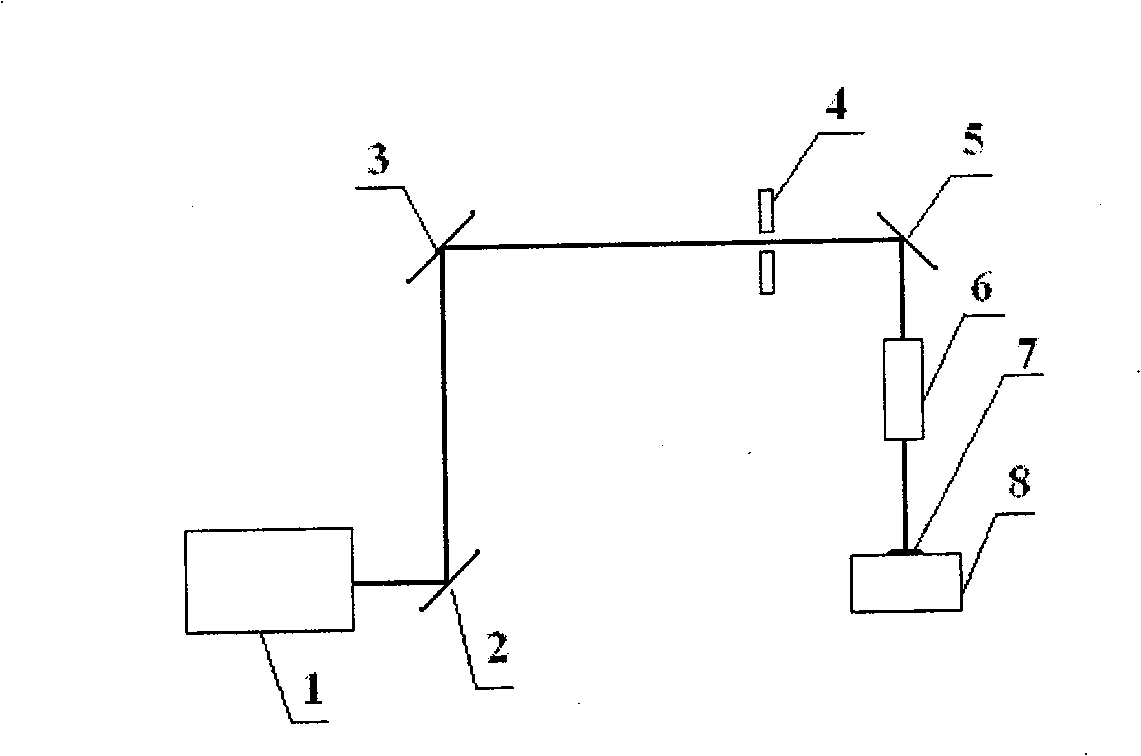

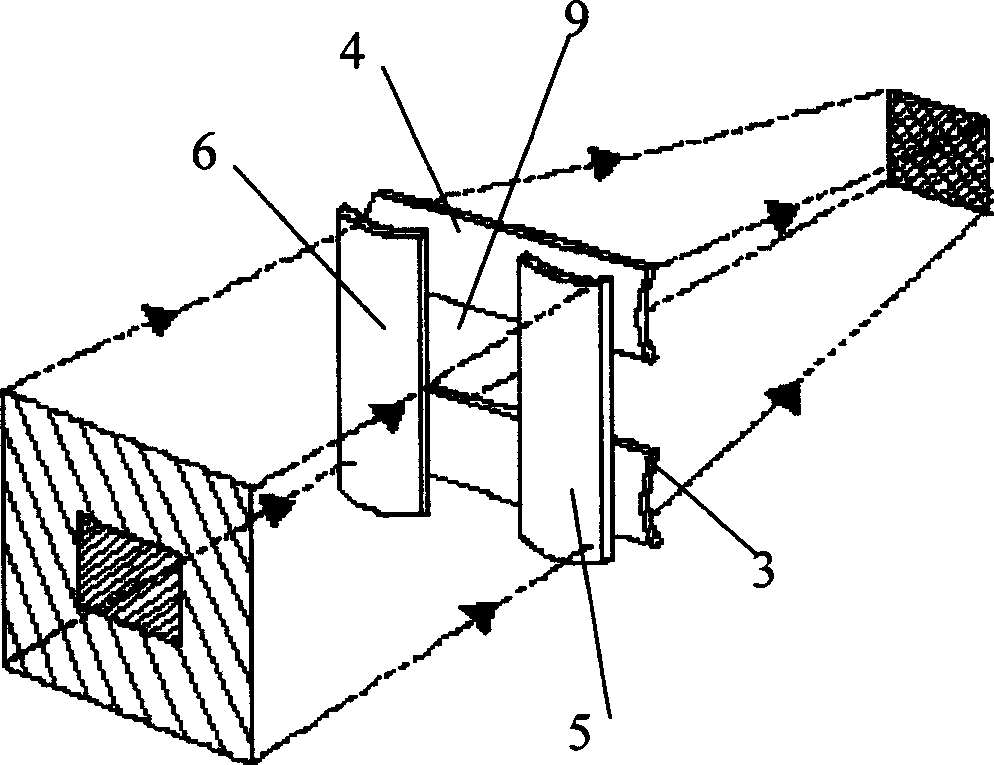

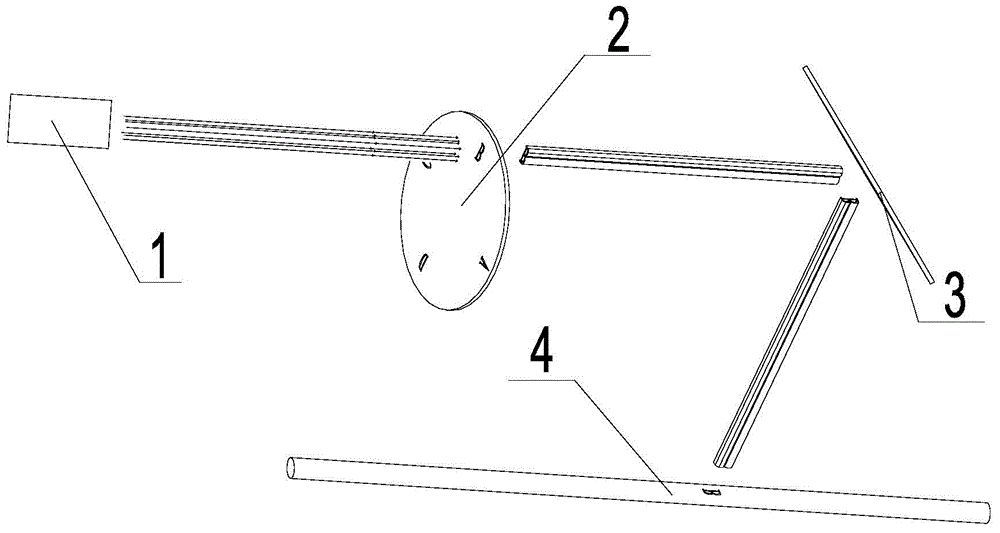

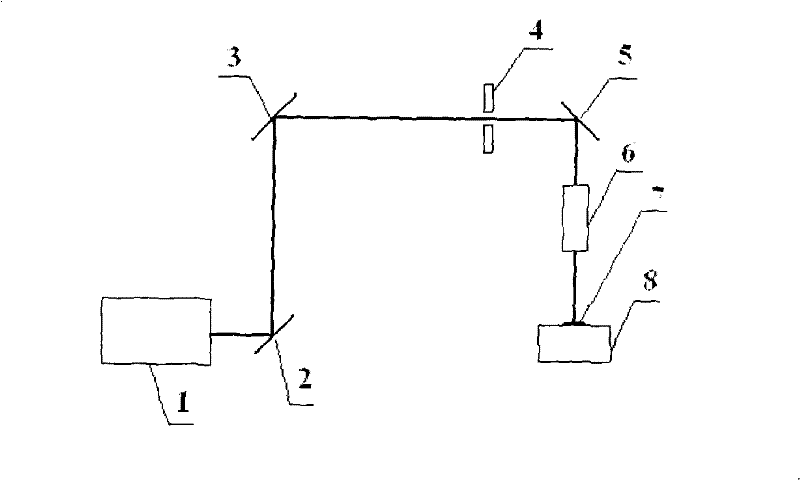

Method of rapidly generating and controlling polyvinylidene fluoride conducting layer

The invention relates to a method of rapidly generating and controlling a polyvinylidene fluoride conducting layer, belonging to the preparing and laser micro-processing field of conducting polymer. An excimer laser mask direct writing light path system is used for texturing the surface of a sample, and then an excimer laser irradiation light path system is used for modifying the sample after the texturing. Defects are implanted into the surface of the sample. The modifying period is shortened, and simultaneously the conducting region around the defected parts of the modified region which are distributed symmetrically can be controlled due to the introduction of the defects.

Owner:BEIJING UNIV OF TECH

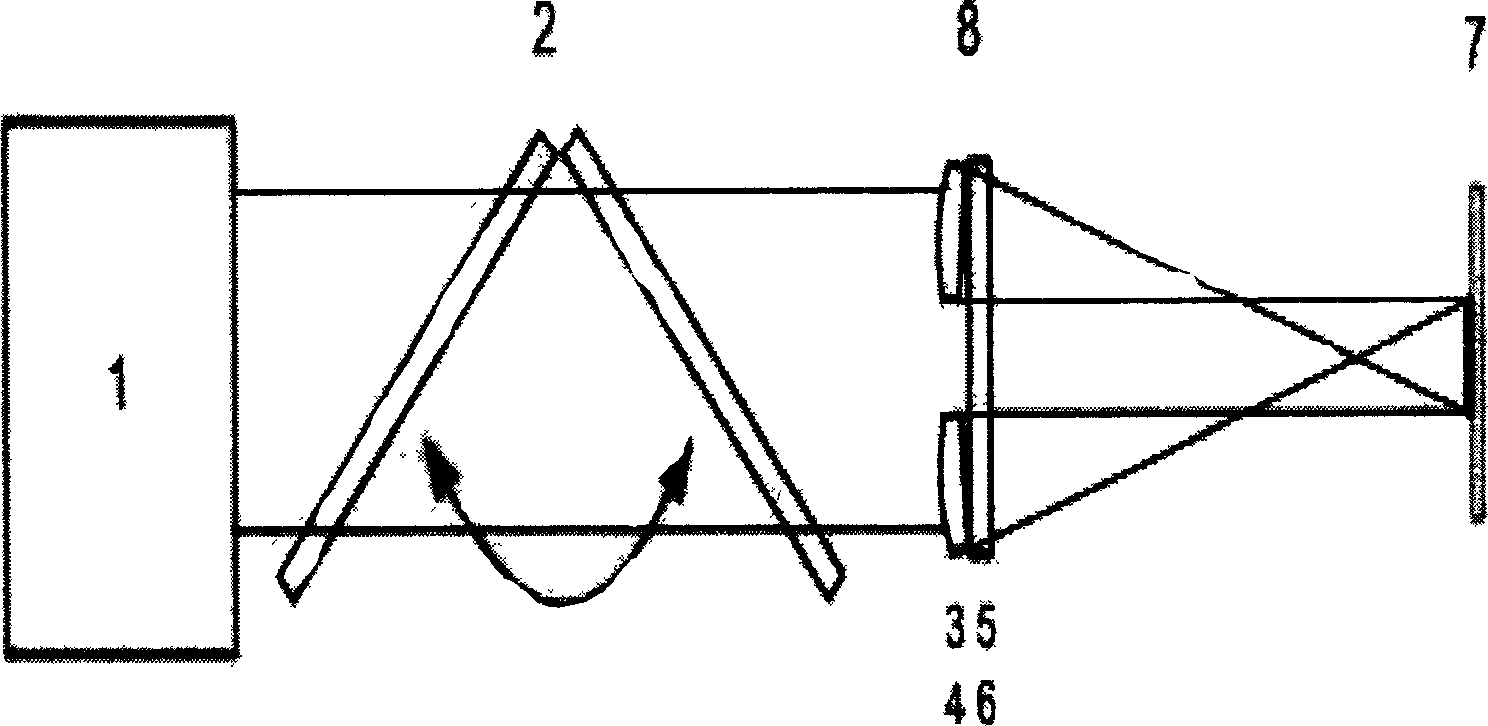

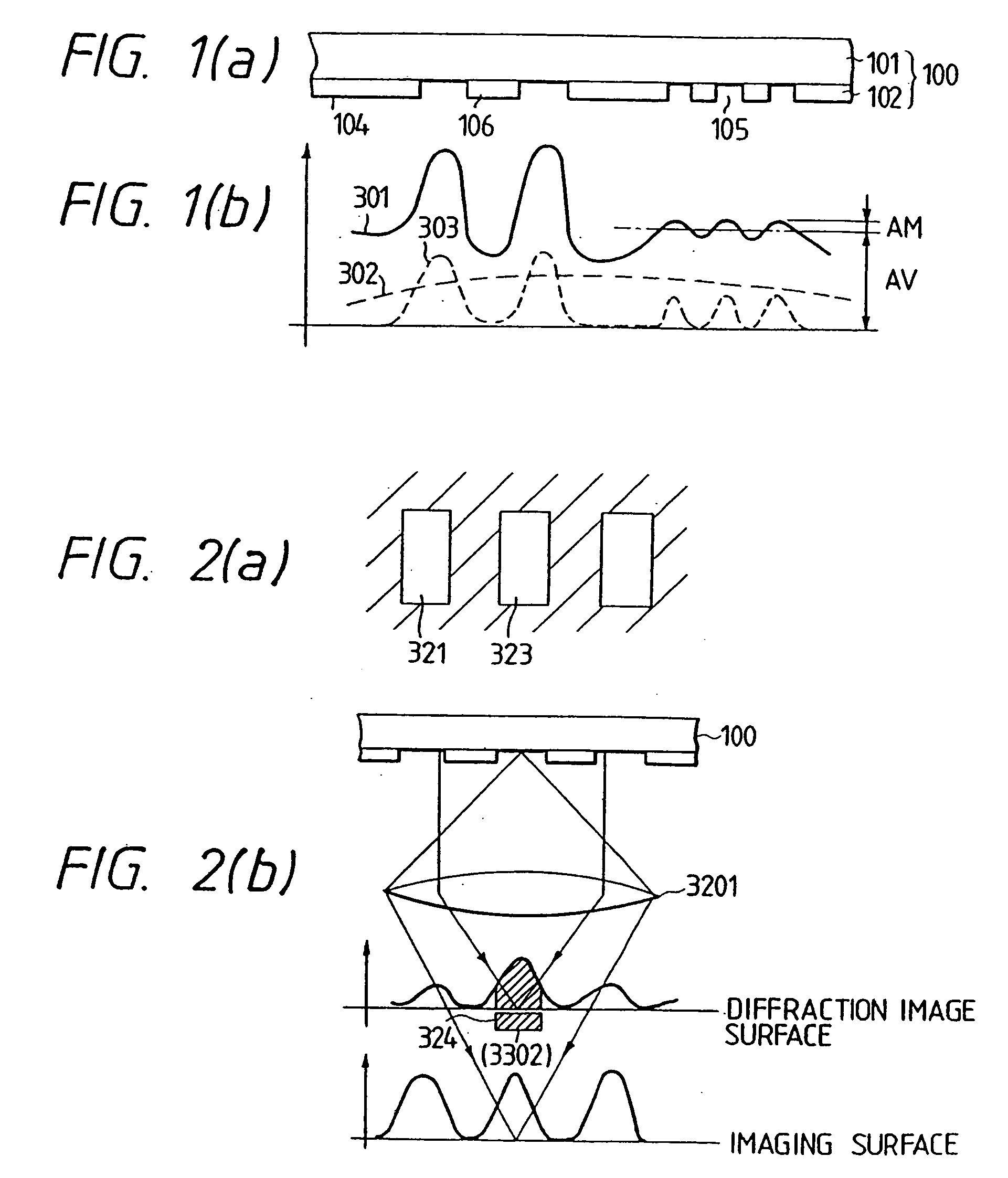

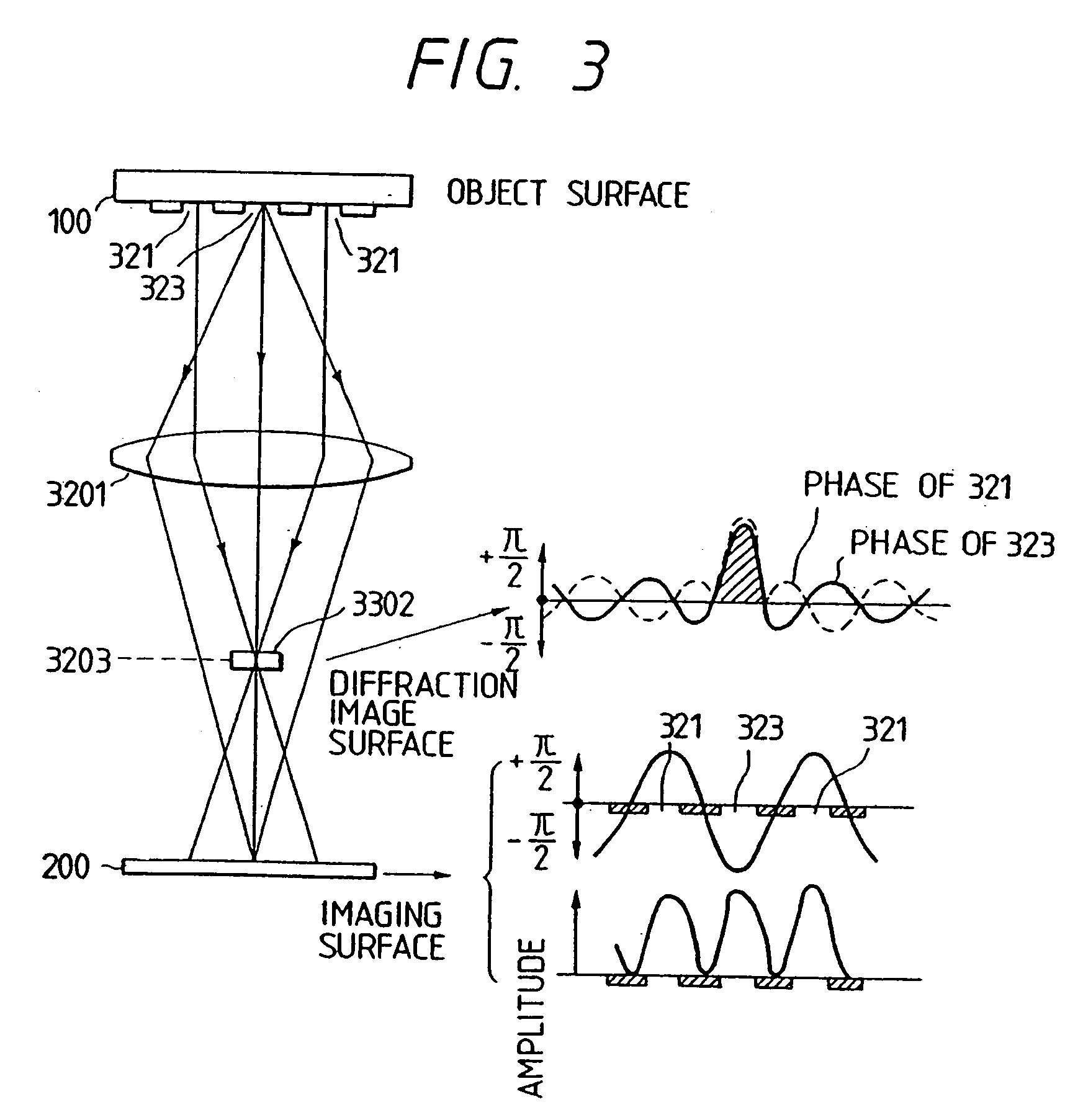

Simplified fly eye type light beam homogenizer

A simplified fly-eye light beam equalizer for excimer laser is similar to a 3*3 fly's eye lens array formed by two groups of cylindrical quatz lenses whose generating lines are perpendicular to each other. It central part is a square or rectangular space channel. When an excimer laser with rectangular or square light spot is radiating the equalizer, it can directly pass through central space channel. For the other part, the laser beam is divided into 9 components, which are then added to equalize the light intensity. Its advantages are simple structure and high effect.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Aviation fluorine-containing polymer insulated wire and cable surface laser character printing method

InactiveCN104361956ANot easy to change colorSimple methodConductor/cable markingAviationChange color

The invention provides an aviation fluorine-containing polymer insulated wire and cable surface laser character printing method. The method has the advantages that the surfaces of a wire and a cable are irradiated with excimer lasers with center laser density, so that titanium dioxide molecules contained in insulating or sheath materials of the wire and the cable change color due to induction, the original white color is changed into the black color, and the purpose of identification is achieved; the identification generated according to the method is permanent and can pass a fastness test of any standard, and meanwhile characters are clear. For a wire and a cable which are not round, the character printing purpose can not be achieved by the adoption of a type wheel printing method.

Owner:HUAINAN XINGUANGSHEN OPTICAL FIBER CABLE

Method for fabricating thin-film transistor

ActiveUS9142425B2Inhibited DiffusionSimple molding processSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorOxide semiconductor

A method for fabricating a thin-film transistor is described. A structure is provided, including a substrate transmitting an excimer laser light, a diffusion prevention film on the substrate, a gate electrode and a gate insulating film on the diffusion prevention film, and an oxide semiconductor layer on the gate insulating film. The structure is irradiated with an excimer laser light from the side of the substrate, so that two outer regions of the oxide semiconductor layer beside the region corresponding to the gate electrode are irradiated by the excimer laser light, with the gate electrode as a mask, to be reduced in resistance and thereby one of the two outer regions forms a source region and the other one forms a drain region. The diffusion prevention film includes a SiN:F film containing fluorine in a SiN film.

Owner:NISSIN ELECTRIC CO LTD

Water-soluble resin composition and method of forming pattern therewith

InactiveCN1947068AIncreasing the thicknessImprove finenessRadiation applicationsSemiconductor/solid-state device manufacturingResistMiniaturization

A water-soluble resin composition for use in a pattern forming method involving applying a coating layer to a resist pattern formed by an ArF-responsive radiation-sensitive resin composition and expanding the width of the resist pattern so as to attain effective miniaturization of trench pattern and hole pattern, wherein the degree of dimensional shrinkage of resist pattern layer is increased over that of the prior art and wherein the dependence of rough / dense resist pattern on dimensional shrinkage degree is reduced; and a method of forming a pattern with the use of the water-soluble resin composition. There is provided a water-soluble resin composition for use in the above pattern forming method applicable to ArF excimer laser irradiation, comprising a water-soluble resin, a generator capable of generating an acid when heated, a surfactant, a crosslinking agent and a solvent containing water. Further, there is provided a method of forming a pattern with the use of the water-soluble resin composition.

Owner:MERCK PATENT GMBH

Light-emitting diode and its manufacturing method

InactiveCN1744333AImprove reliabilitySolution to short lifeSemiconductor devicesWavelengthSilicon dioxide

The LED includes following structure: P type contact electrode on a base plate 1; luminous single package on the upper array of the p type electrode; reflection insulation film composed of cross laminated silicon dioxide layer and silicon nitride layer is located between luminous single packages; N type contact electrode in cancellate shape is on luminous single packages. Characters of the method are: a thick layer of gold is vaporized on P type electrode and base plate 1; pressing and heating up the two thick gold layers, the method bonds epitaxial wafer with the base plate 1; using quasi molecule laser in short wave, the method exposes sapphire base plate 7, acts on buffer layer, and puts it in tube inside high-temperature furnace with hedrogen cloride being inducted to in order to peel off plate 7. The LED solves issues: poor electrical and heat conductivities of plate 7; and effect of current concentration. The LED possesses advantages of good reliability and long service life.

Owner:东莞市福地电子材料有限公司

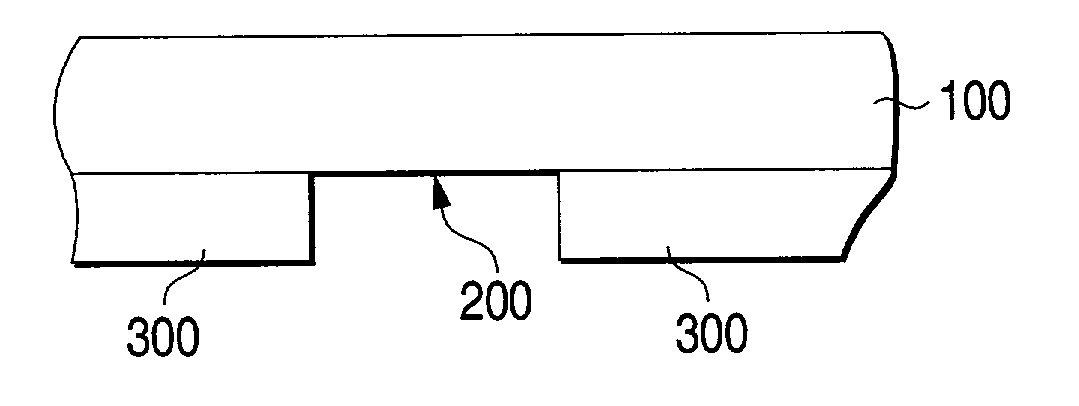

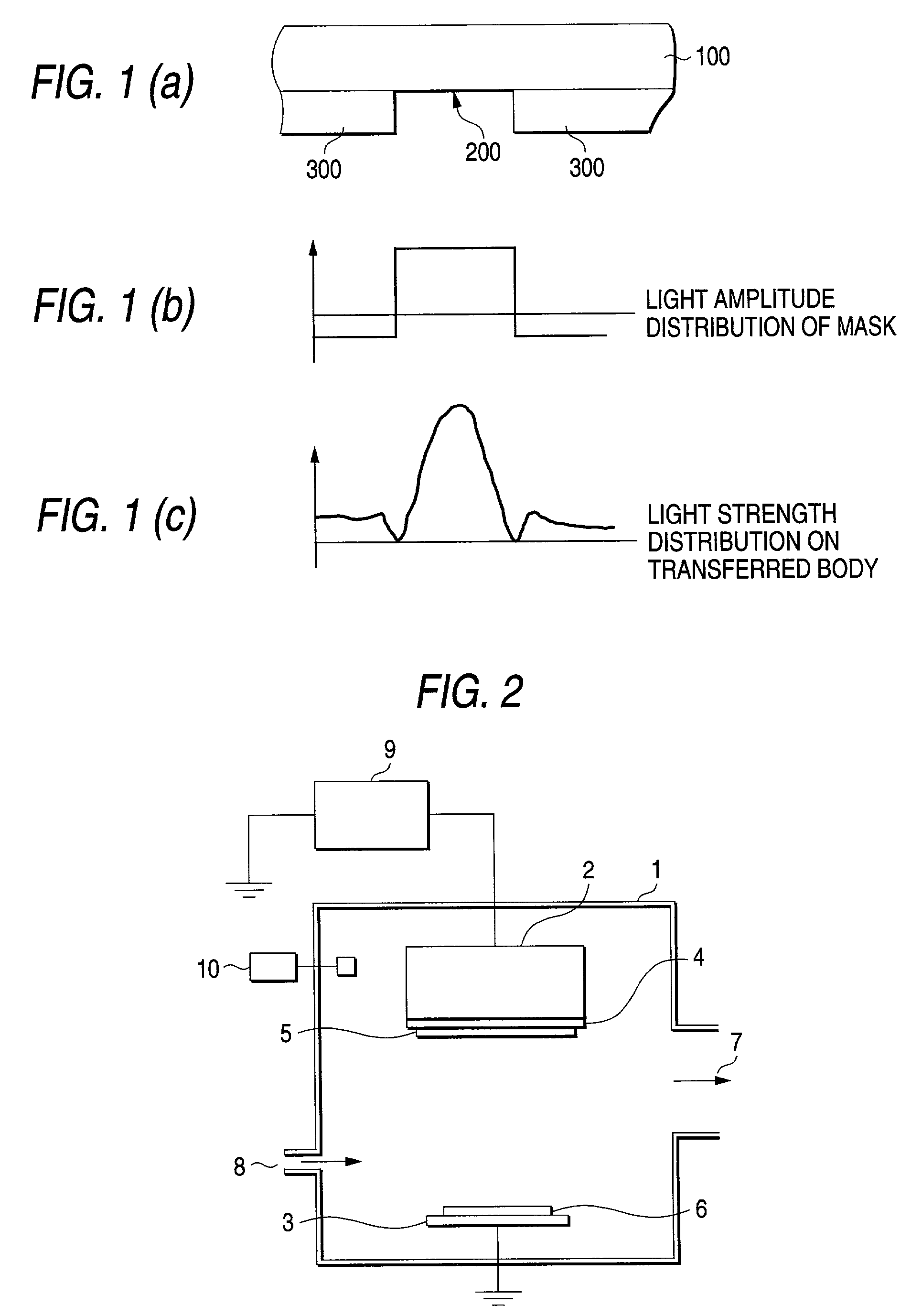

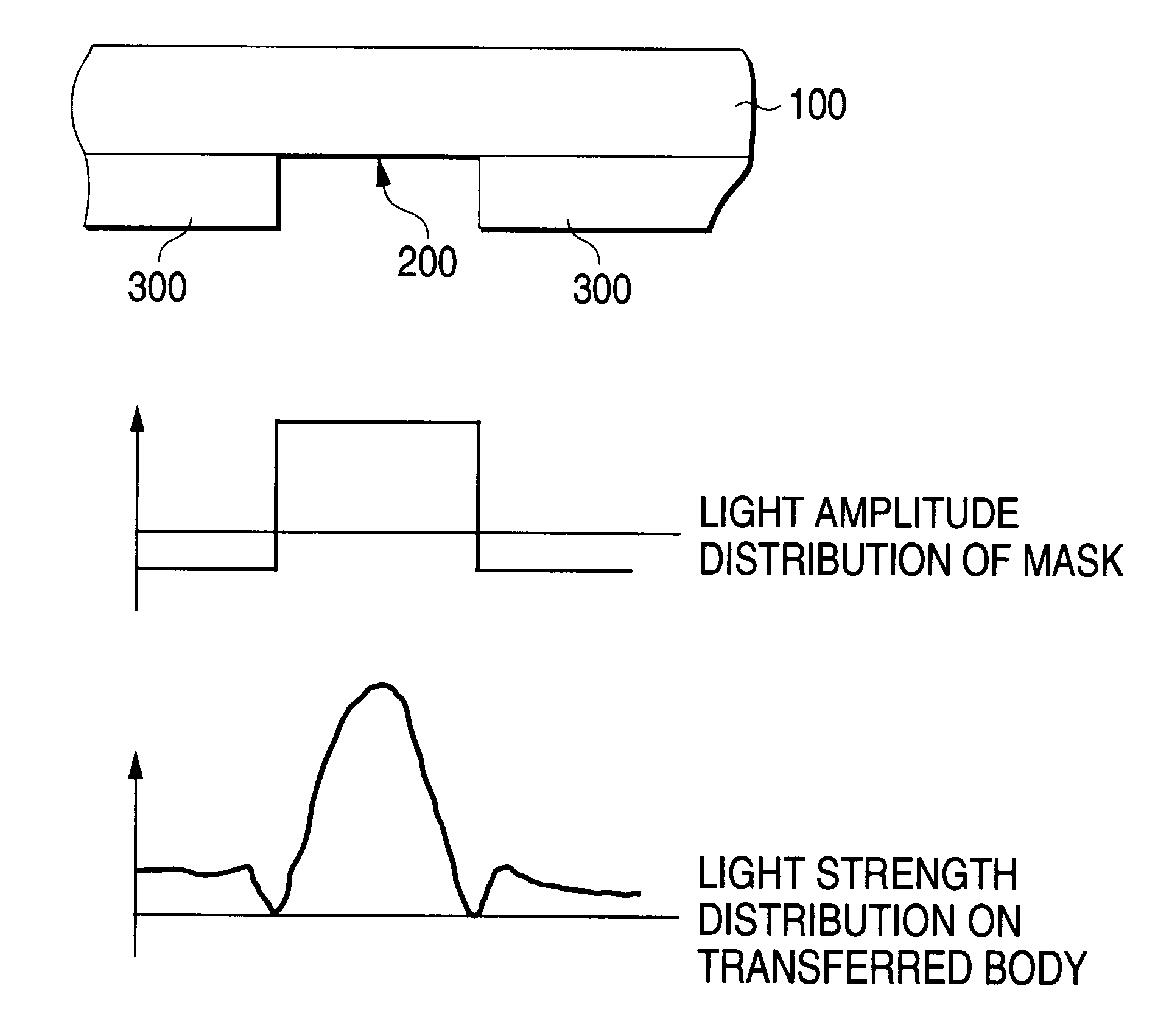

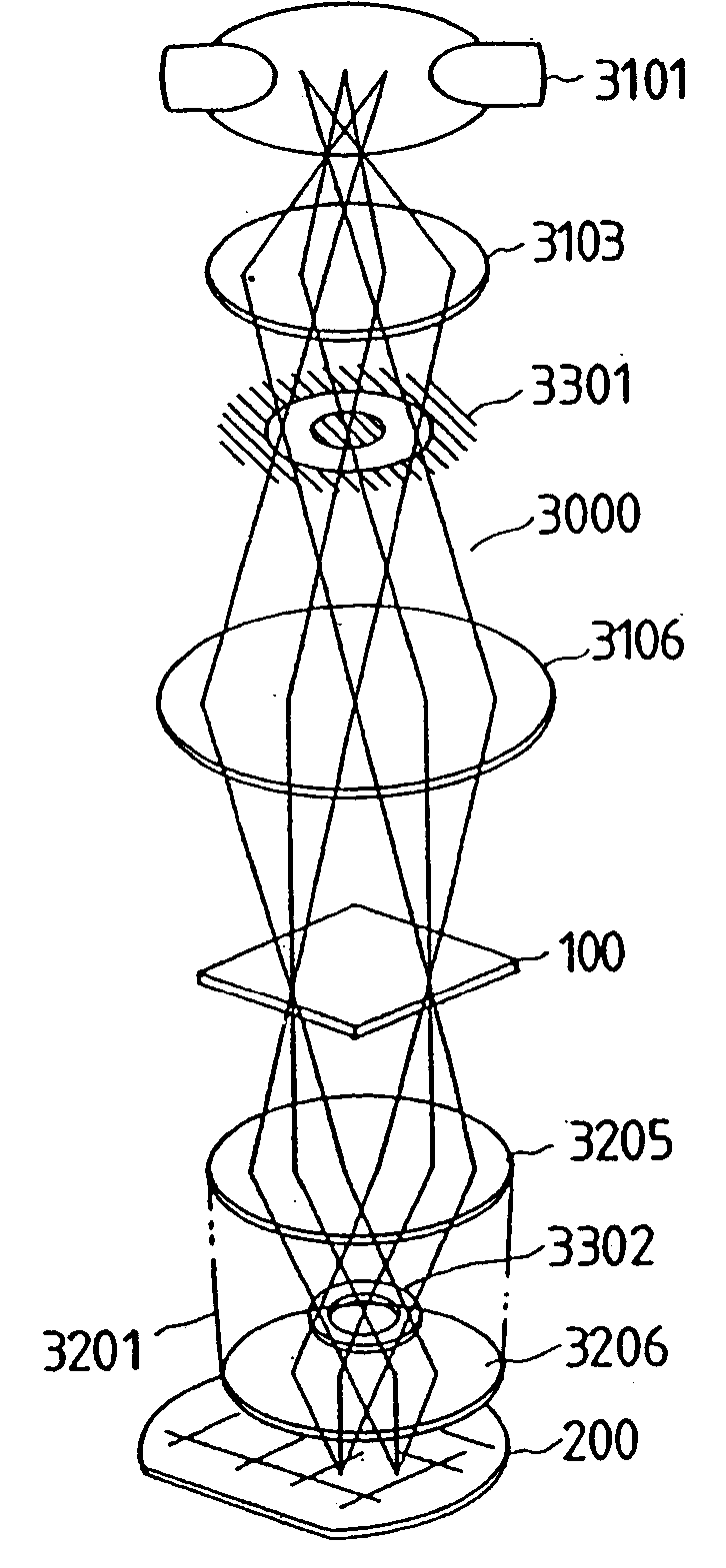

Exposure apparatus and method

InactiveUS20050196705A1Improve accuracyHigh-precision detectionRadiation applicationsSemiconductor/solid-state device manufacturingResistDevice material

A production method of a semiconductor device which includes the steps of exposing a resist coated on a substrate of a semiconductor device by projecting a light pattern on the substrate of the semiconductor device, developing the resist exposed by the light pattern to form a wafer pattern with the resist, and etching the substrate on which the wafer pattern with the resist is formed. In the step of exposing the light pattern is formed by illuminating a mask with excimer laser light having an annular shape.

Owner:RENESAS ELECTRONICS CORP

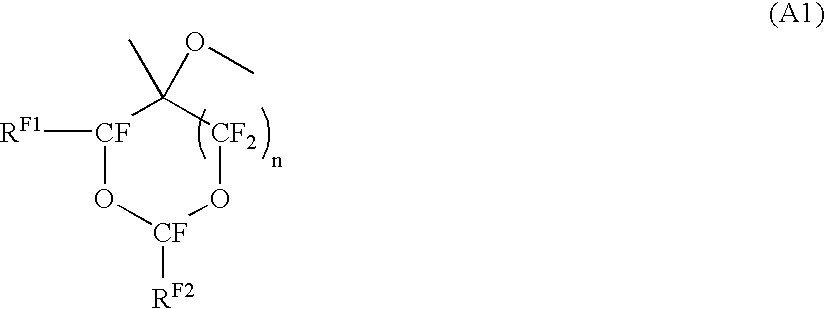

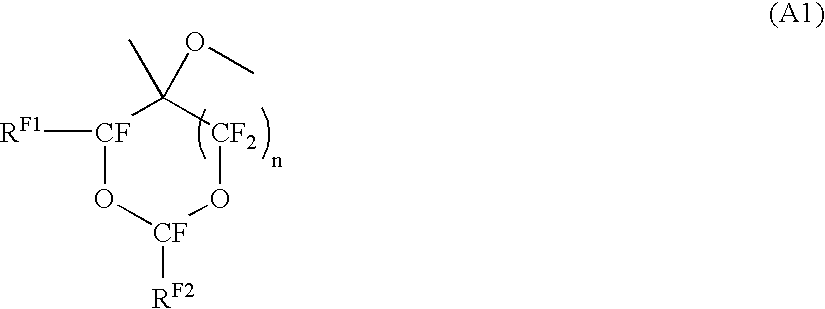

Pellicle and novel fluoropolymer

InactiveUS20060240222A1High transparency and durabilityHigh transparencyOrganic chemistryPolyanhydride adhesivesOxygen atomAdhesive

It is to provide a useful fluoropolymer excellent in transparency and durability to a short wavelength light (an ArF excimer laser having an irradiation wavelength of 193 nm and a F2 excimer laser having an irradiation wavelength of 157 nm) as e.g. a pellicle material. A pellicle wherein a polymer (I) to be used for a pellicle membrane and / or an adhesive is a polymer essentially containing the following unit (1). The unit (1) is a unit containing a fluorine atom, wherein a chain forming the polymer main chain comprises a carbon atom and an etheric oxygen atom, at least one carbon atom forming the main chain is a carbon atom forming a cyclic group, and at least one etheric oxygen atom forming the main chain is an oxygen atom forming no cyclic group. For example, a unit represented by the following formula (A1) (wherein n is 1 or 2, RF1 is —F or —CF3, and RF2 is —F or a C1-5 perfluoroalkyl group):

Owner:ASAHI GLASS CO LTD

A method for rapid generation and control of conductive polyvinylidene fluoride conductive layers

The invention is a method for rapidly producing and controlling a conductive polyvinylidene fluoride conductive layer, and belongs to the field of preparation of conductive polymers and laser micro-processing. The invention utilizes the excimer laser mask direct writing optical path system to texture the surface of the sample, and then uses the excimer laser irradiation optical path system to modify the textured sample. Implanting defects on the surface of the sample first not only shortens the modification time, but at the same time, due to the introduction of defects, the conductive area can be controlled around the defect parts with symmetrical distribution in the modified area.

Owner:BEIJING UNIV OF TECH

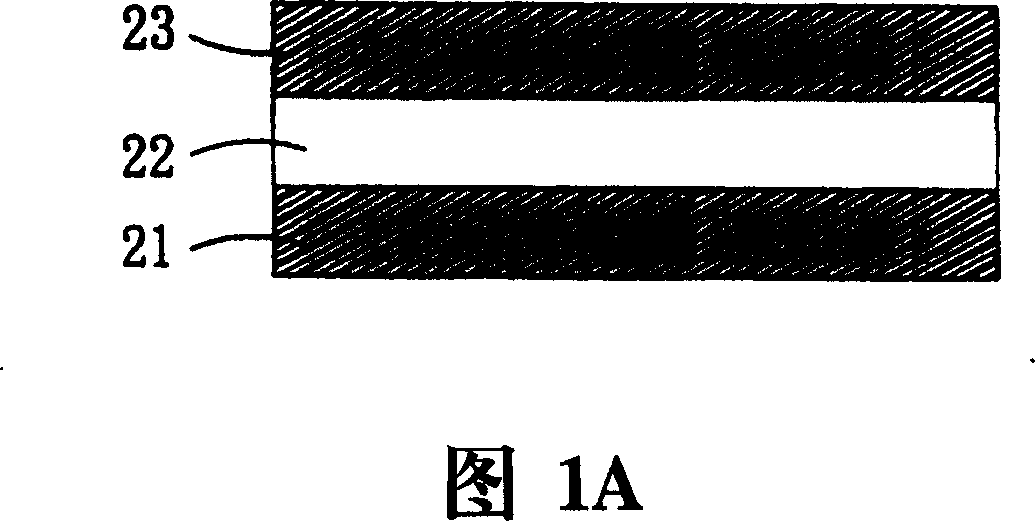

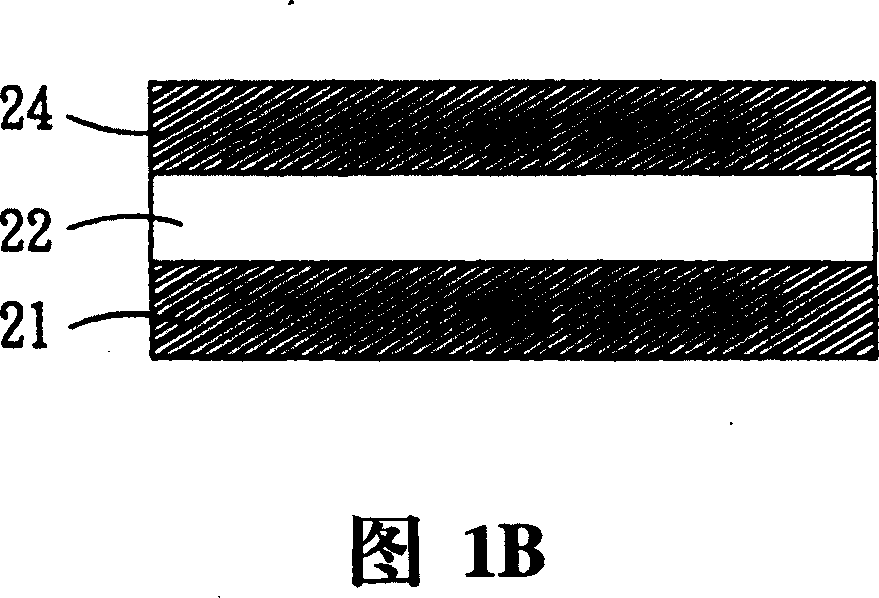

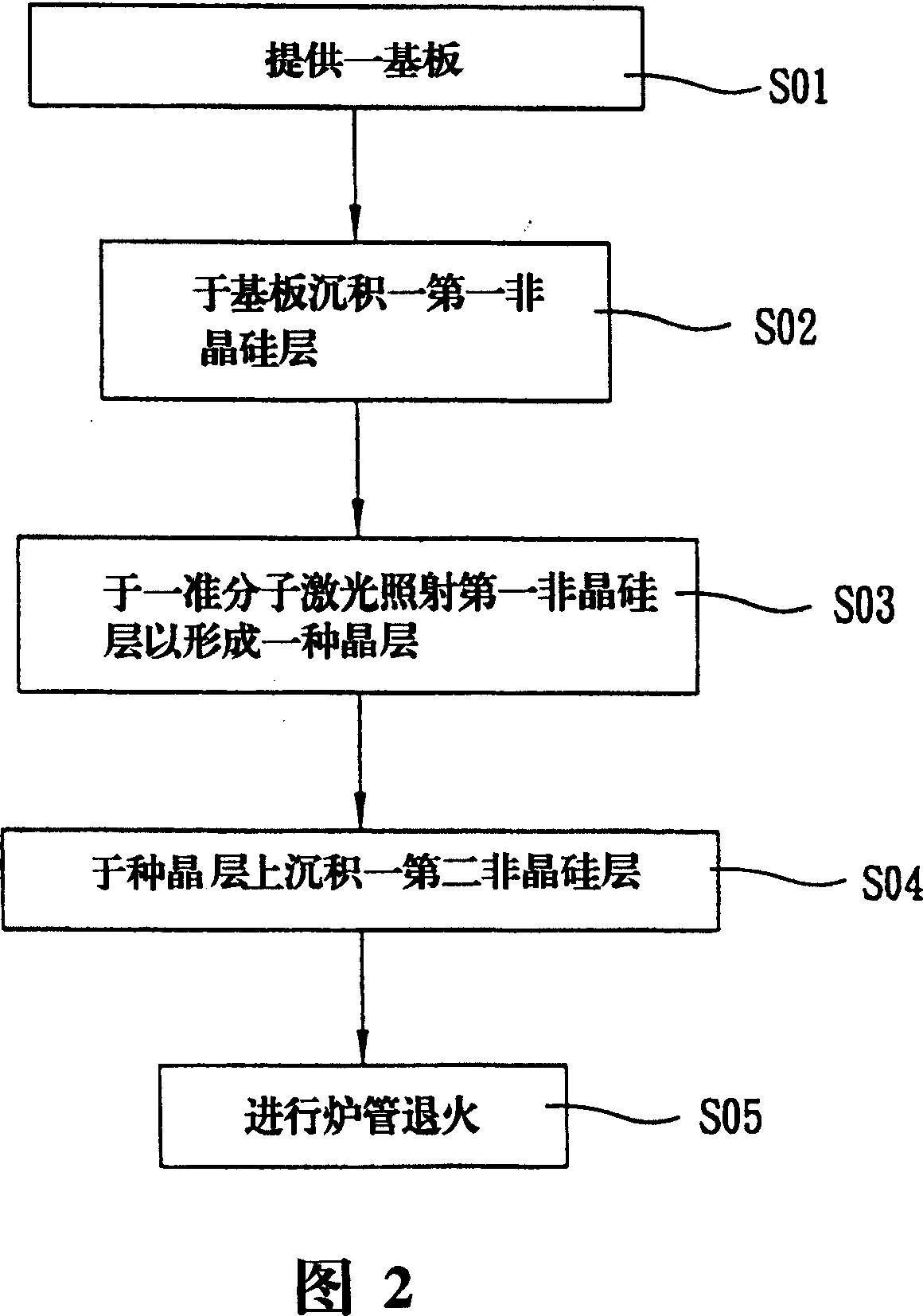

Method for manufacturing polysilicon of thin-film transistor

The invention relates to a making method of polycrystalline silicon of a film transistor, containing the following steps: providing a substrate; depositing a first noncrystalline silicon layer on the substrate; using a quasimolecule laser to irradiate the first noncrystalline silicon layer to form a crystal seed layer; depositing a second noncrystalline silicon layer on the crystal seed layer; making furnace tube annealing.

Owner:RITDISPLAY

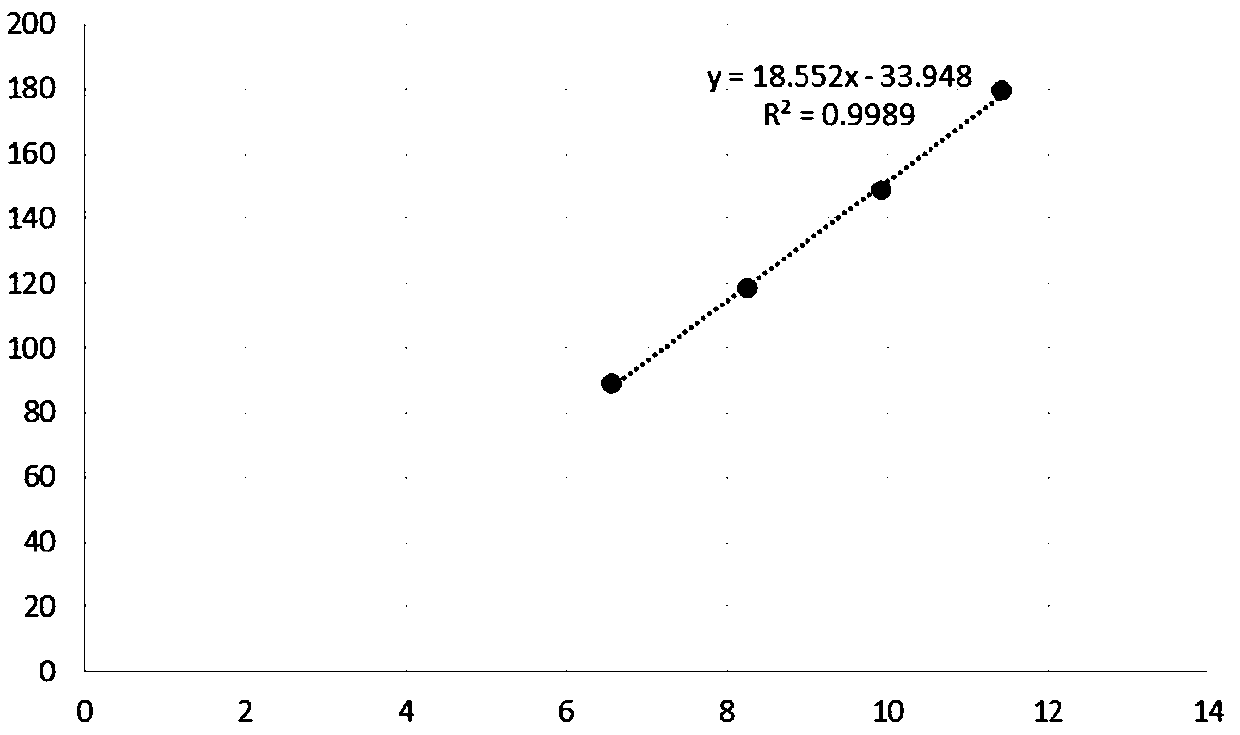

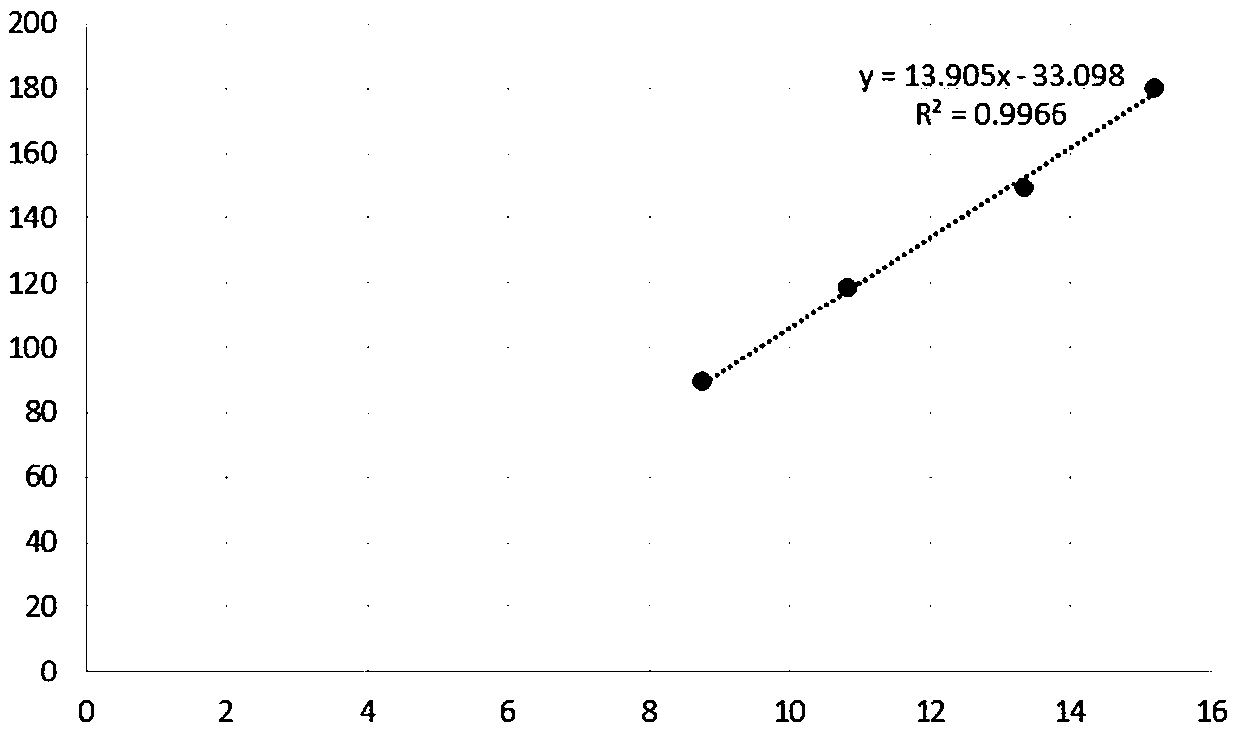

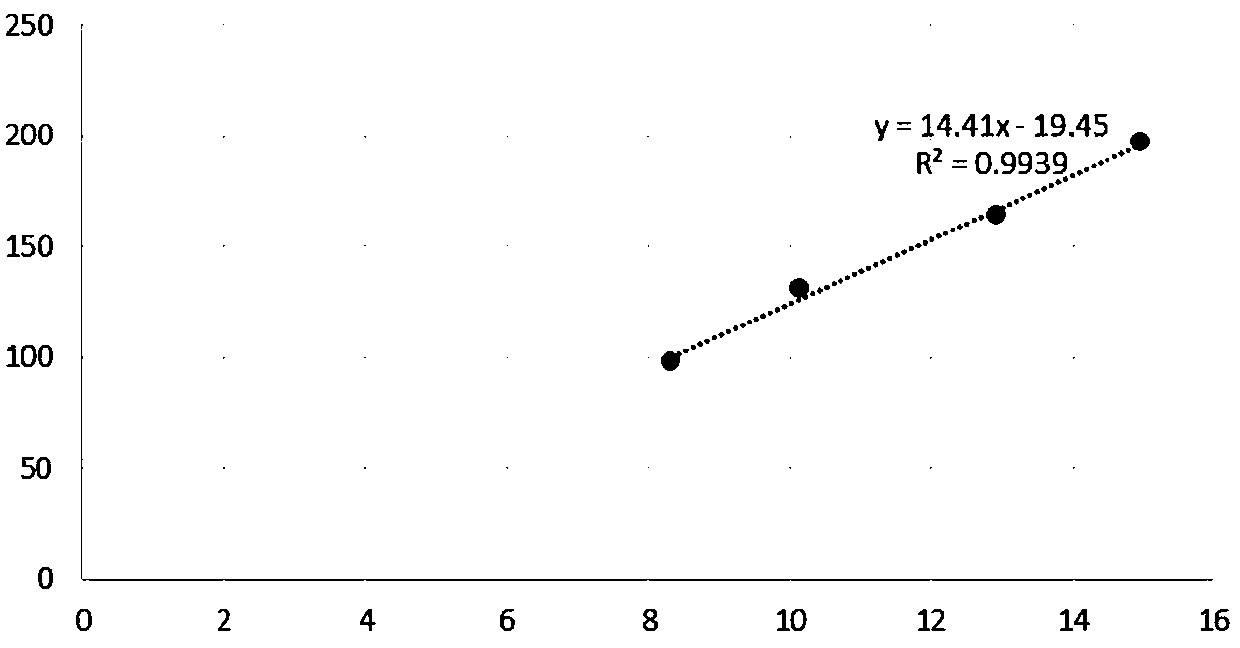

Automatic correction method for excimer laser annealing process OED

PendingCN110993491AReduce product quality deviationTimely correction and adjustmentImage enhancementSemiconductor/solid-state device testing/measurementControl systemPhysical chemistry

The invention discloses an automatic correction method for an excimer laser annealing process OED, which does not need manual operation, is convenient to implement, reliable in performance, efficientand accurate, and comprises the following steps: acquiring a real-time Mura value by adopting a Mura quantification method, and reporting the Mura value to a control system; comparing the Mura value with a preset Mura value range, if the Mura value exceeds the preset Mura value range, controlling the excimer laser annealing device to correct the optimal energy density. The correction method comprises the steps that (1) a substrate with an amorphous silicon layer on the surface is provided, and the amorphous silicon layer is divided into a plurality of areas; (2) excimer lasers with different energy densities are used for irradiating all the areas respectively; (3) the Mura value of each region is quantified by adopting a Mura quantification method, wherein the energy density of the excimerlaser corresponding to the region with the minimum Mura value is the optimal energy density; and (4) the product substrate with the amorphous silicon layer is irradiated by the excimer laser annealing device through the excimer laser with the optimal energy density.

Owner:信利(仁寿)高端显示科技有限公司

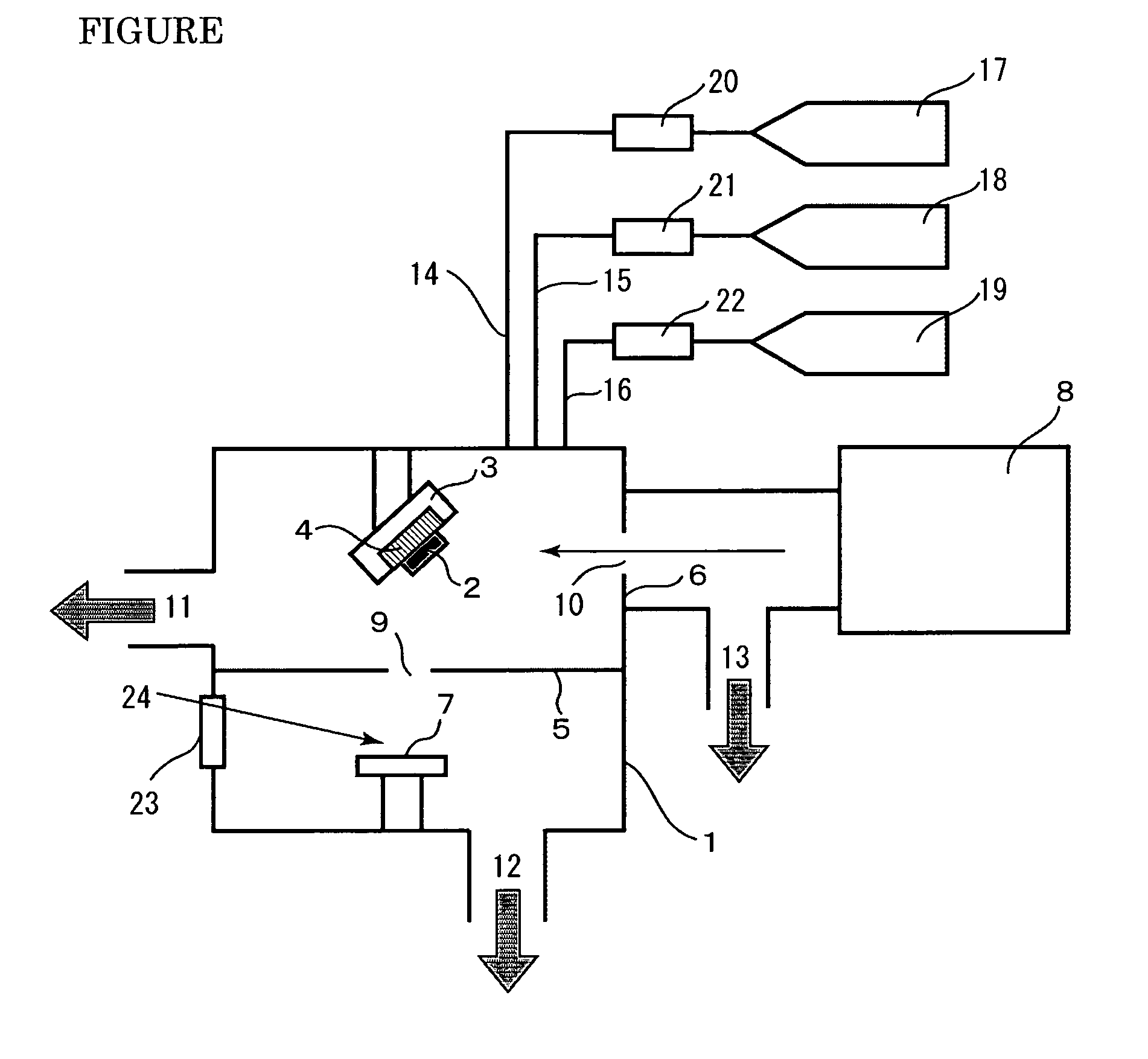

Laser crystallization system and laser crystallization method

ActiveUS20200388493A1Avoid radiationReduce hydrogen concentrationSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingPhysical chemistryLaser crystallization

A laser crystallization system includes a transfer part that transfers a substrate on which an amorphous silicon thin film is deposited into a chamber, a laser irradiation part that irradiates an excimer laser to the substrate for crystallization of the amorphous silicon thin film in the chamber, a stage that supports the substrate in the chamber, a measuring part that measures a light transmittance value of the substrate, and a controller that controls the laser irradiation part to irradiate the excimer laser to the substrate when the light transmittance value is equal to or lower than a reference transmittance value and controls the laser irradiation part not to irradiate the excimer laser to the substrate when the light transmittance value is higher than the reference transmittance value.

Owner:SAMSUNG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com