A method for rapid generation and control of conductive polyvinylidene fluoride conductive layers

A polyvinylidene fluoride and conductive layer technology, applied in the field of conductive polymer preparation and laser micromachining, can solve the problems of artificial control of non-conductive areas, rapid preparation of conductive layer obstacles, upper limit of laser energy density, etc., to avoid time-consuming and energy, fast preparation speed and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

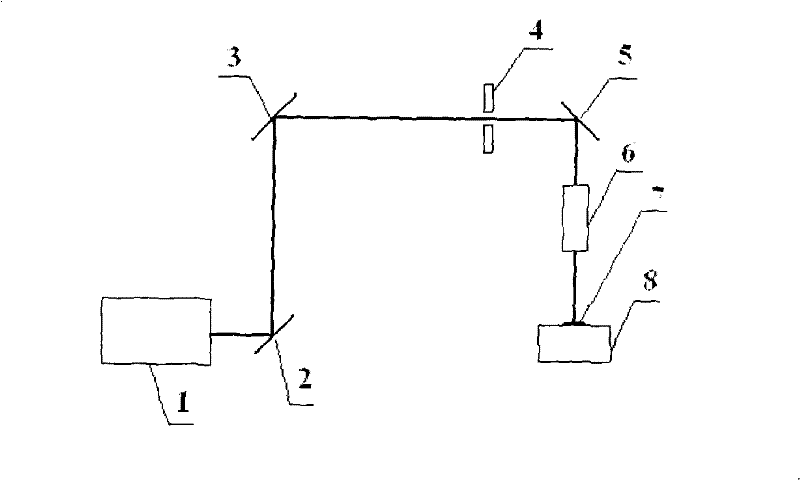

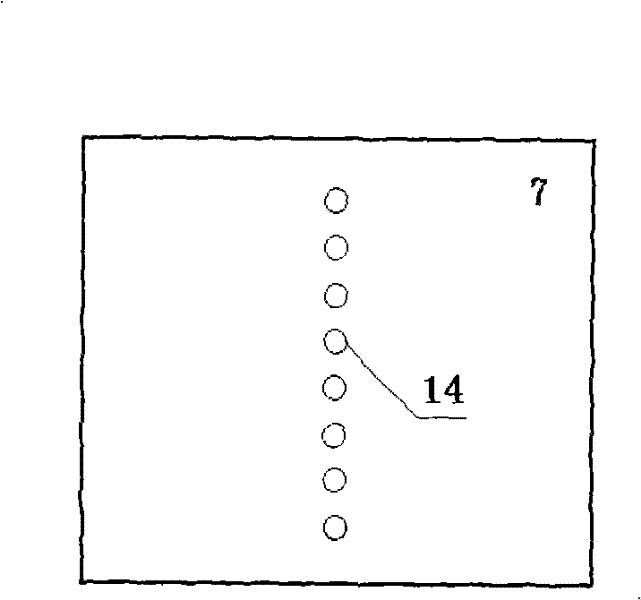

[0045] First, in the attached figure 1 In the shown excimer laser mask direct writing optical path system, a circular mask with a diameter of 4mm is selected, and microgrooves are constructed on the surface 7 of the PVDF film. The diameter of the microgrooves is 0.26mm, and the distance between each microgroove is 1cm. Etching 8 microgrooves arranged in a straight line 14, as attached image 3 shown. During the experiment, the energy of laser 1 was 200mJ, the repetition frequency was 4Hz, and each microhole was etched with 30 pulses. Then, the He-Ne laser is used for positioning, the three-dimensional workbench 8 is turned on, the laser 1 is turned on, and the texture of the micro-pattern is automatically completed through the laser control software and the three-dimensional workbench control software.

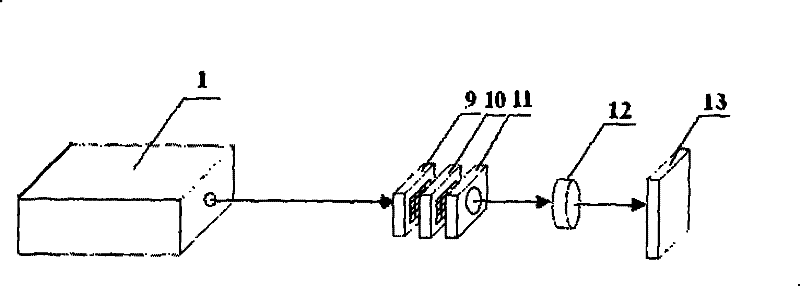

[0046] The textured sample is placed on the workbench 13 of the excimer laser irradiation optical system, collimated by the He-Ne laser, and the optical path is adjusted so ...

Embodiment 2

[0048] First, in the attached figure 1 In the shown excimer laser mask direct writing optical path system, a circular mask with a diameter of 4mm is selected, and microgrooves are constructed on the surface 7 of the PVDF film. The diameter of the microgrooves is 0.26mm, and the distance between two adjacent microgrooves is 1cm. Graphics, continuous etching three rows and three columns of 9 equally spaced microgrooves 15, as attached Figure 4 shown. During the experiment, the energy of laser 1 was 300mJ, the repetition frequency was 4Hz, and each microhole was etched with 30 pulses. Then, the He-Ne laser is used for positioning, the three-dimensional workbench is turned on, the laser is turned on, and the texture of the micro-pattern is automatically completed through the laser control software and the three-dimensional workbench control software. Turn off the laser and turn off the 3D workbench.

[0049] The textured sample is placed on the workbench 13 of the excimer lase...

Embodiment 3

[0051] First, in the attached figure 1 In the excimer laser mask direct writing optical system shown, a circular mask with a diameter of 4 mm is selected. During the experiment, the energy of laser 1 is 400 mJ, the repetition frequency is 4 Hz, and the table speed is 10 mm / min. Structure microgroove on PVDF film surface 7, width is 0.26mm, and length is the microchannel 16 of 8cm, as attached Figure 5 shown. Then, the He-Ne laser is used for positioning, the three-dimensional workbench is turned on, the laser is turned on, and the texture of the micro-pattern is automatically completed through the laser control software and the three-dimensional workbench control software. Turn off the laser and turn off the 3D workbench.

[0052] The textured sample is placed on the workbench 13 of the excimer laser irradiation optical system, collimated by the He-Ne laser, and the optical path is adjusted so that it has a complete spot shape. Set the output energy of the laser to 300mJ, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com