Method of rapidly generating and controlling polyvinylidene fluoride conducting layer

A polyvinylidene fluoride and conductive layer technology, which is applied in the preparation of conductive polymers and in the field of laser micromachining, can solve the problems of artificial control of non-conductive areas, rapid preparation of conductive layer obstacles, random occurrence of active centers, etc., to avoid time-consuming and energy, fast preparation speed, and controllable conductive area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

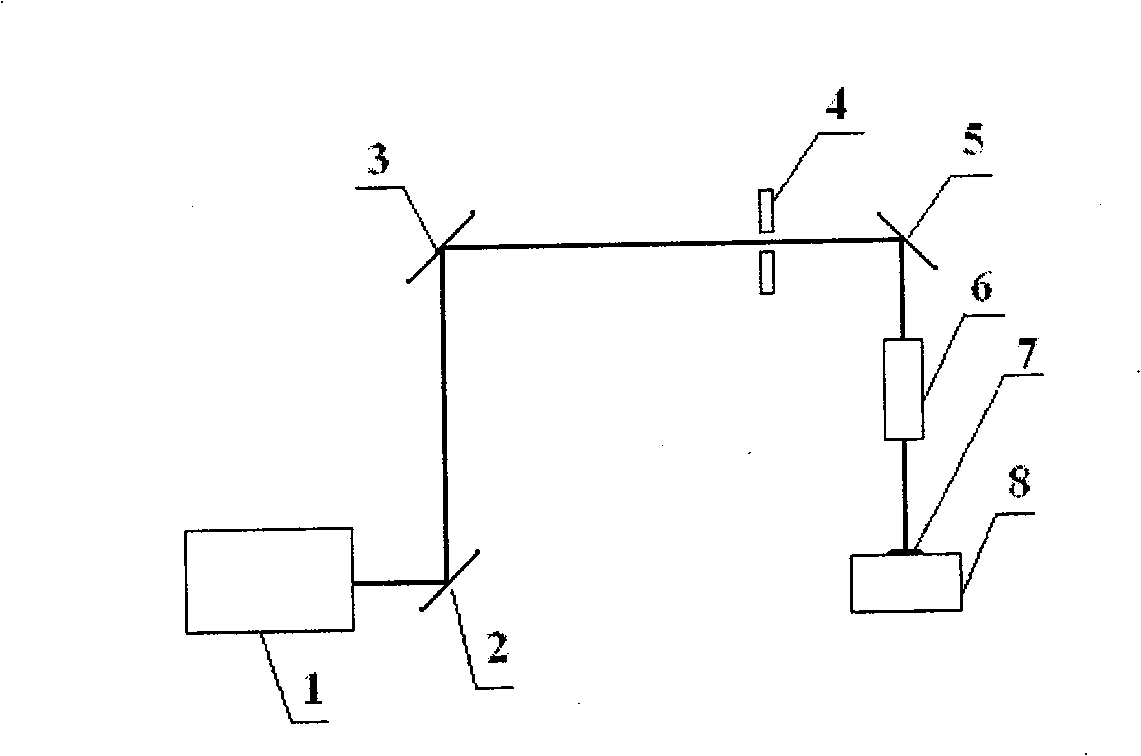

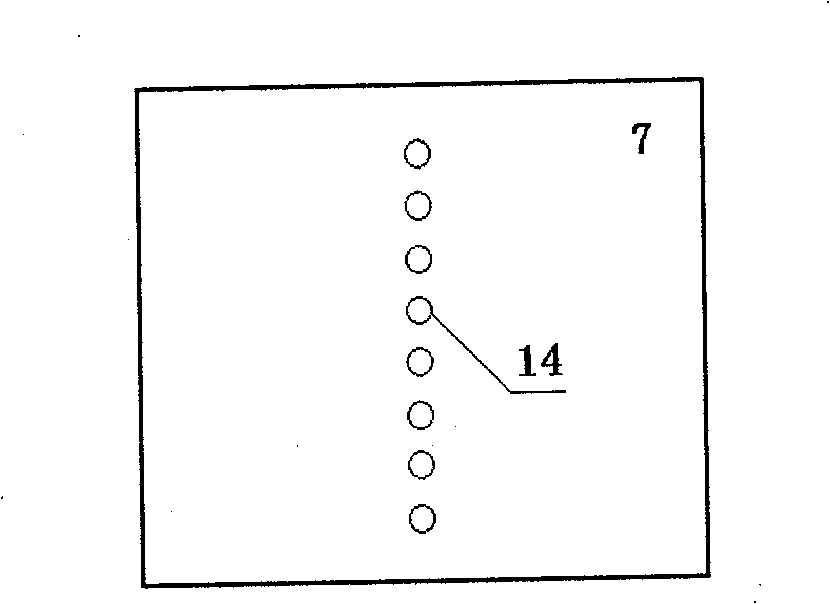

[0045] First, in the attached figure 1 In the shown excimer laser mask direct writing optical path system, a circular mask with a diameter of 4mm is selected, and microgrooves are constructed on the surface 7 of the PVDF film. The diameter of the microgrooves is 0.26mm, and the distance between each microgroove is 1cm. Etching 8 microgrooves arranged in a straight line 14, as attached image 3 shown. During the experiment, the energy of laser 1 was 200mJ, the repetition frequency was 4Hz, and each microhole was etched with 30 pulses. Then, the He-Ne laser is used for positioning, the three-dimensional workbench 8 is turned on, the laser 1 is turned on, and the texture of the micro-pattern is automatically completed through the laser control software and the three-dimensional workbench control software.

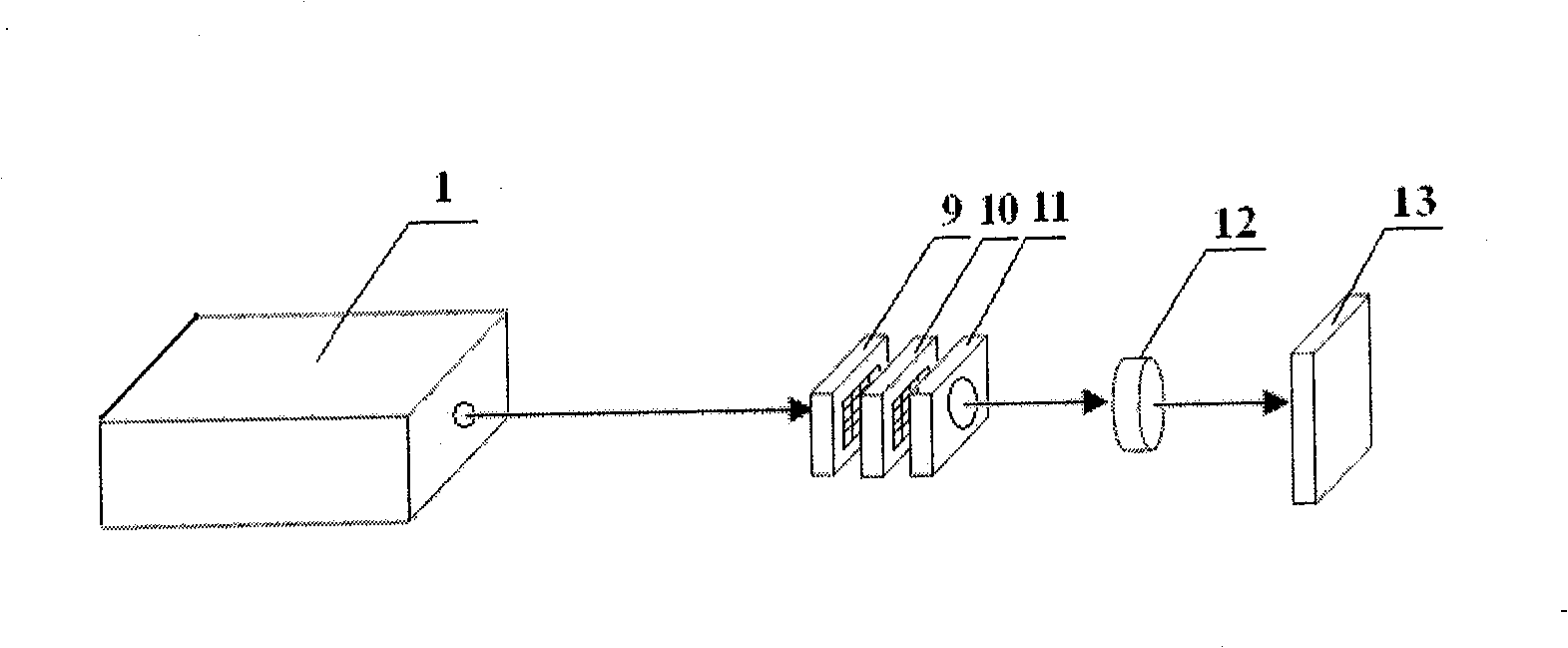

[0046] The textured sample is placed on the workbench 13 of the excimer laser irradiation optical system, collimated by the He-Ne laser, and the optical path is adjusted so ...

Embodiment 2

[0048] First, in the attached figure 1 In the shown excimer laser mask direct writing optical path system, a circular mask with a diameter of 4mm is selected, and microgrooves are constructed on the surface 7 of the PVDF film. The diameter of the microgrooves is 0.26mm, and the distance between two adjacent microgrooves is 1cm. Graphics, continuous etching three rows and three columns of 9 equally spaced microgrooves 15, as attached Figure 4 shown. During the experiment, the energy of laser 1 was 300mJ, the repetition frequency was 4Hz, and each microhole was etched with 30 pulses. Then, the He-Ne laser is used for positioning, the three-dimensional workbench is turned on, the laser is turned on, and the texture of the micro-pattern is automatically completed through the laser control software and the three-dimensional workbench control software. Turn off the laser and turn off the 3D workbench.

[0049] The textured sample is placed on the workbench 13 of the excimer lase...

Embodiment 3

[0051] First, in the attached figure 1 In the excimer laser mask direct writing optical system shown, a circular mask with a diameter of 4 mm is selected. During the experiment, the energy of laser 1 is 400 mJ, the repetition frequency is 4 Hz, and the table speed is 10 mm / min. Structure microgroove on PVDF film surface 7, width is 0.26mm, and length is the microchannel 16 of 8cm, as attached Figure 5 shown. Then, the He-Ne laser is used for positioning, the three-dimensional workbench is turned on, the laser is turned on, and the texture of the micro-pattern is automatically completed through the laser control software and the three-dimensional workbench control software. Turn off the laser and turn off the 3D workbench.

[0052] The textured sample is placed on the workbench 13 of the excimer laser irradiation optical system, collimated by the He-Ne laser, and the optical path is adjusted so that it has a complete spot shape. Set the output energy of the laser to 300mJ, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com