Automatic correction method for excimer laser annealing process OED

An excimer laser and automatic correction technology, which is applied in semiconductor/solid-state device manufacturing, image data processing, instruments, etc., can solve the problems of tediousness, inconvenient implementation, and low correction accuracy, so as to achieve accurate data and reduce product quality deviation , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] An automatic correction method for an excimer laser annealing process OED, comprising the steps of:

[0085] Using an excimer laser annealing device to convert the amorphous silicon on the surface of the substrate into polysilicon; using the Mura quantification method to obtain the real-time Mura value of the substrate, and report the Mura value to the control system;

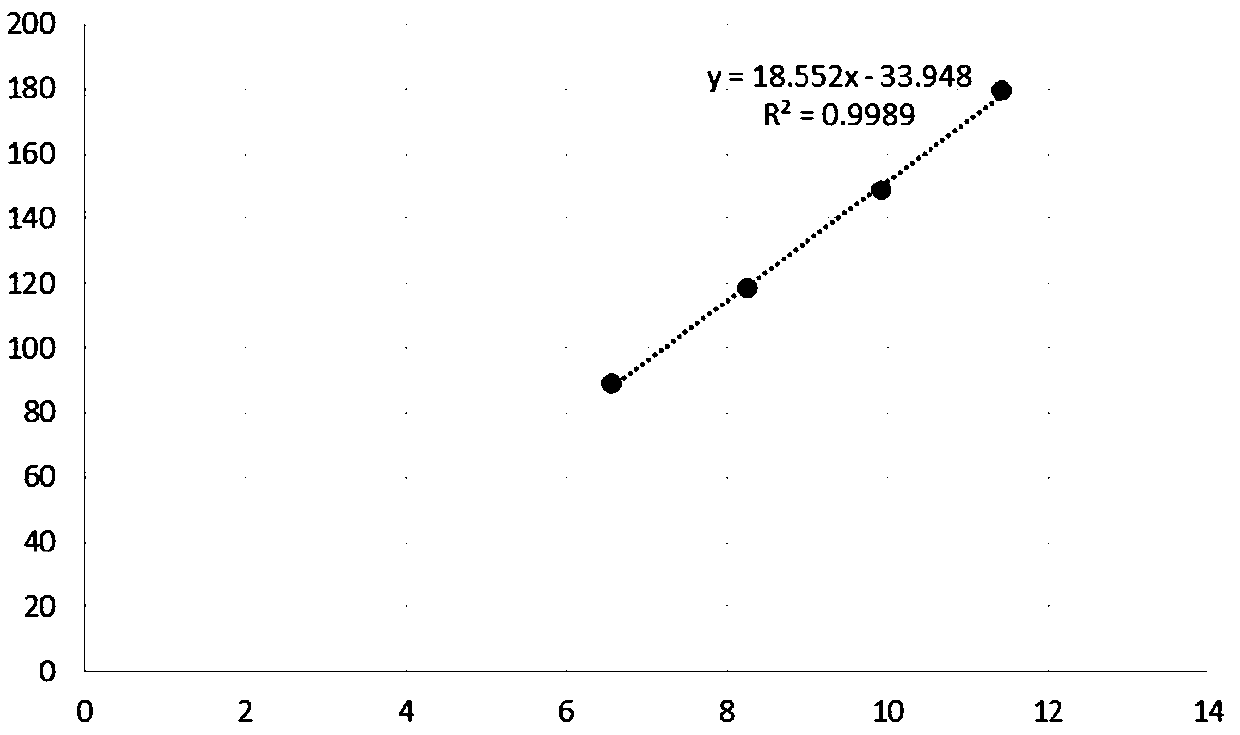

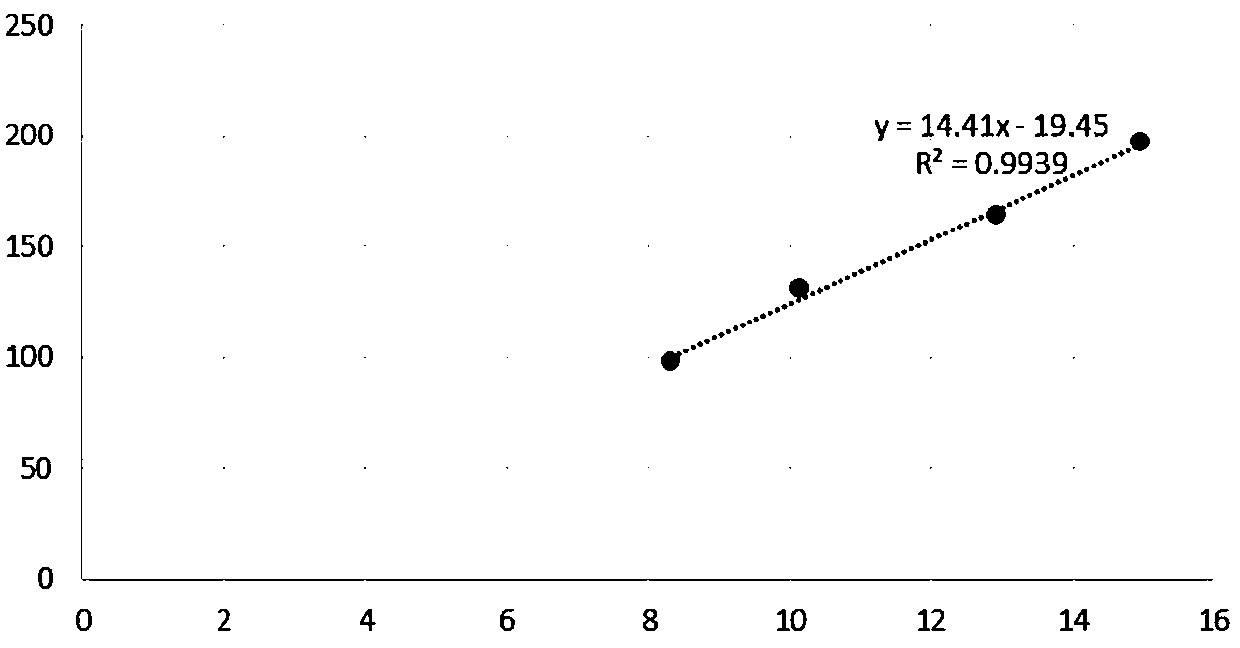

[0086] The control system compares the Mura value with the preset Mura value range, and if the Mura value exceeds the preset Mura value range, the control system controls the excimer laser annealing device to correct the optimal energy density, wherein The method of correcting the optimal energy density is: (1) provide a substrate with an amorphous silicon layer on the surface, and the amorphous silicon layer is divided into multiple regions; (2) perform excimer laser annealing, and use different energies respectively Density excimer laser irradiates each area; (3) Use the Mura quantification method to q...

Embodiment 2

[0098] An automatic correction method for an excimer laser annealing process OED, comprising the steps of:

[0099] Using an excimer laser annealing device to convert the amorphous silicon on the surface of the substrate into polysilicon; using the Mura quantification method to obtain the real-time Mura value of the substrate, and report the Mura value to the control system;

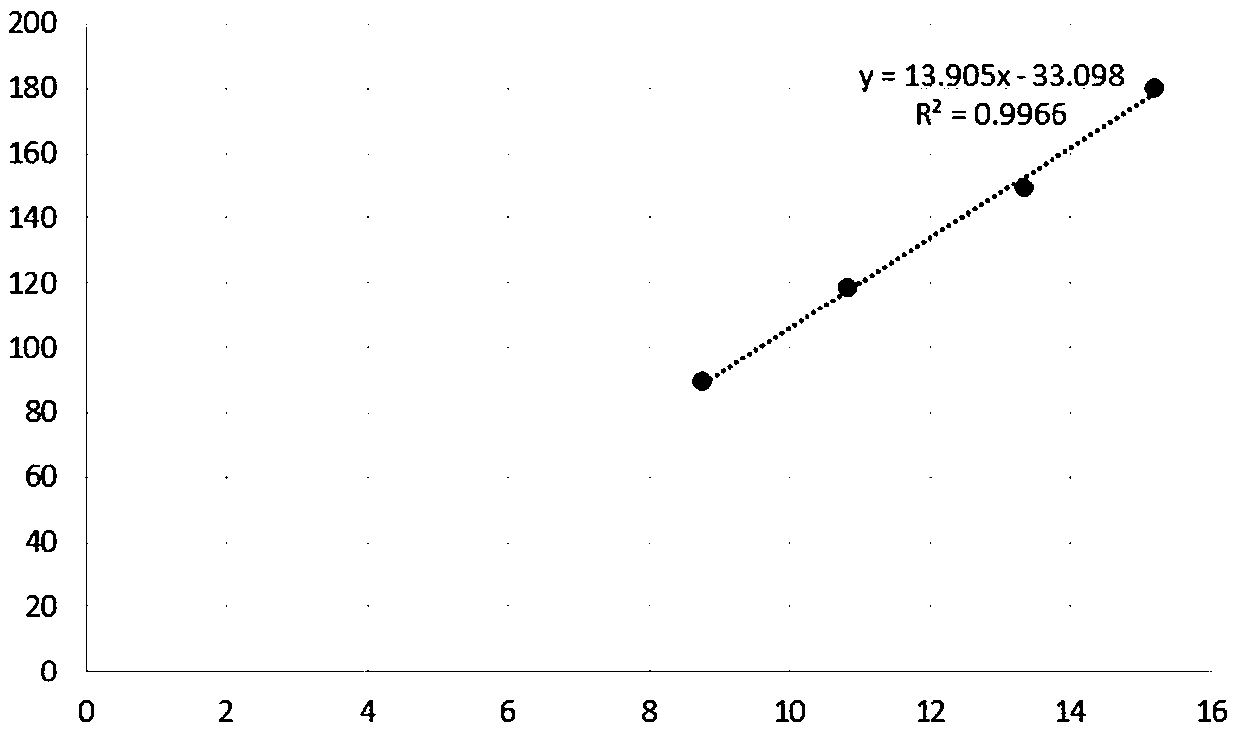

[0100] The control system compares the Mura value with the preset Mura value range, and if the Mura value exceeds the preset Mura value range, the control system controls the excimer laser annealing device to correct the optimal energy density, wherein The method of correcting the optimal energy density is: (1) provide a substrate with an amorphous silicon layer on the surface, and the amorphous silicon layer is divided into multiple regions; (2) perform excimer laser annealing, and use different energies respectively Density excimer laser irradiates each area; (3) Use the Mura quantification method to q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com