Mura quantification method based on excimer laser annealing

A technology of excimer laser and quantification method, which is applied in the quantification field of Mura, can solve the problems of human eye fatigue, strong subjectivity, and different manual judgment standards, and achieve the effect of reducing product quality deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A method for quantifying Mura based on excimer laser annealing, comprising the steps of:

[0055] S1. Under different light intensities, collect Mura images of the same area of the same substrate after excimer laser annealing;

[0056] S2. carry out image processing to described Mura image by picture processing software, obtain the gray scale intensity of each pixel, the area recognition of gray scale intensity less than preset threshold value is Mura area, otherwise identify as non-Mura area; Through picture processing software The grayscale intensity of the pixels in the Mura area is changed to 0, and the grayscale intensity of the pixels in the non-Mura area is changed to 255 to determine the area of the Mura area;

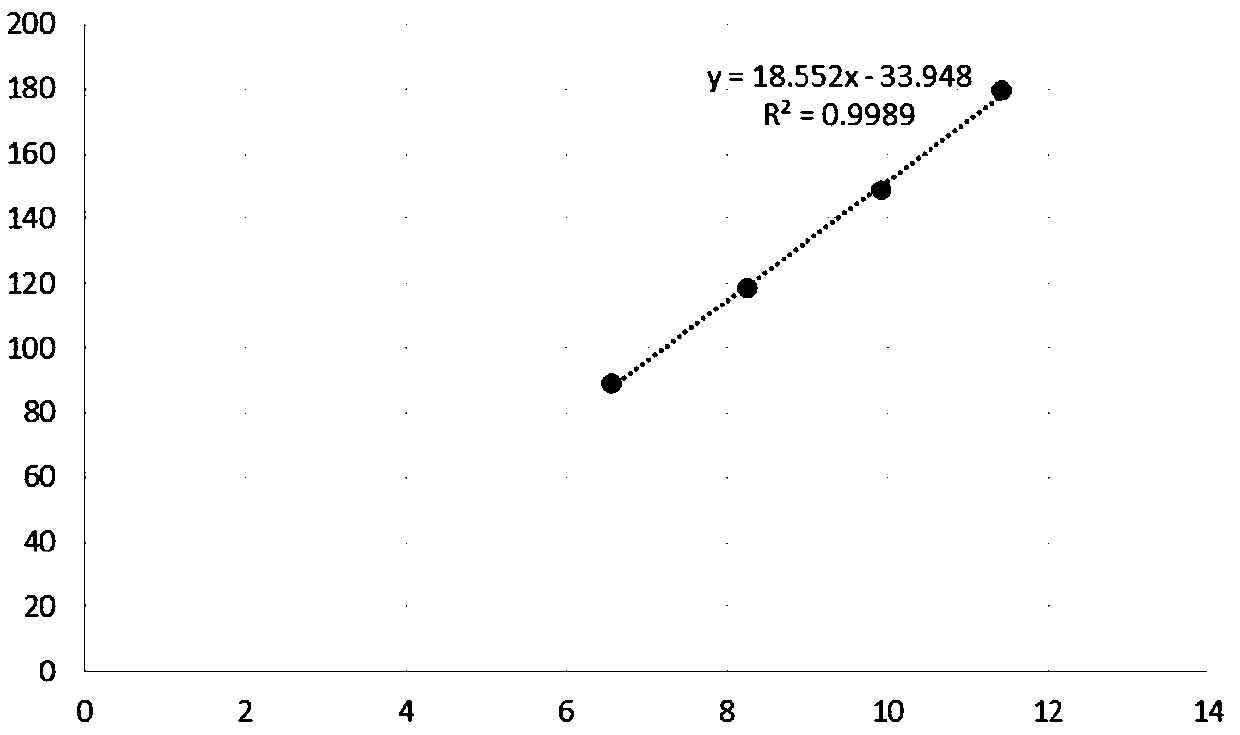

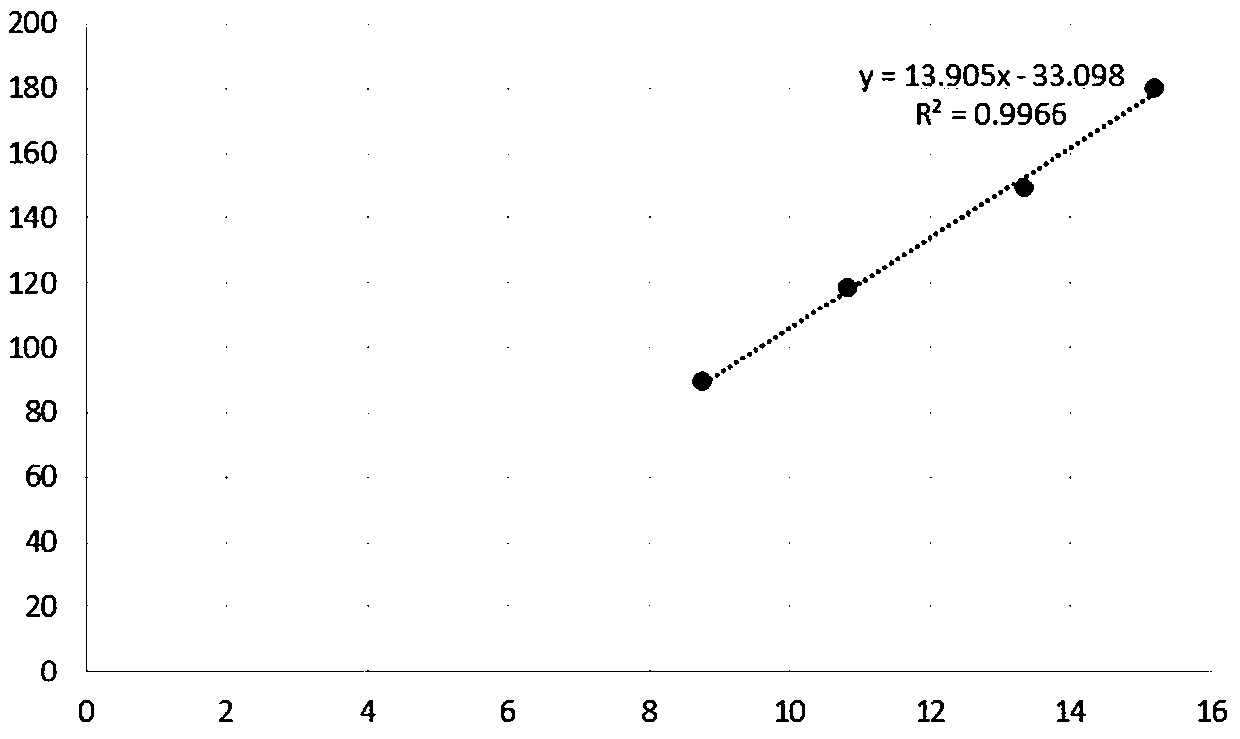

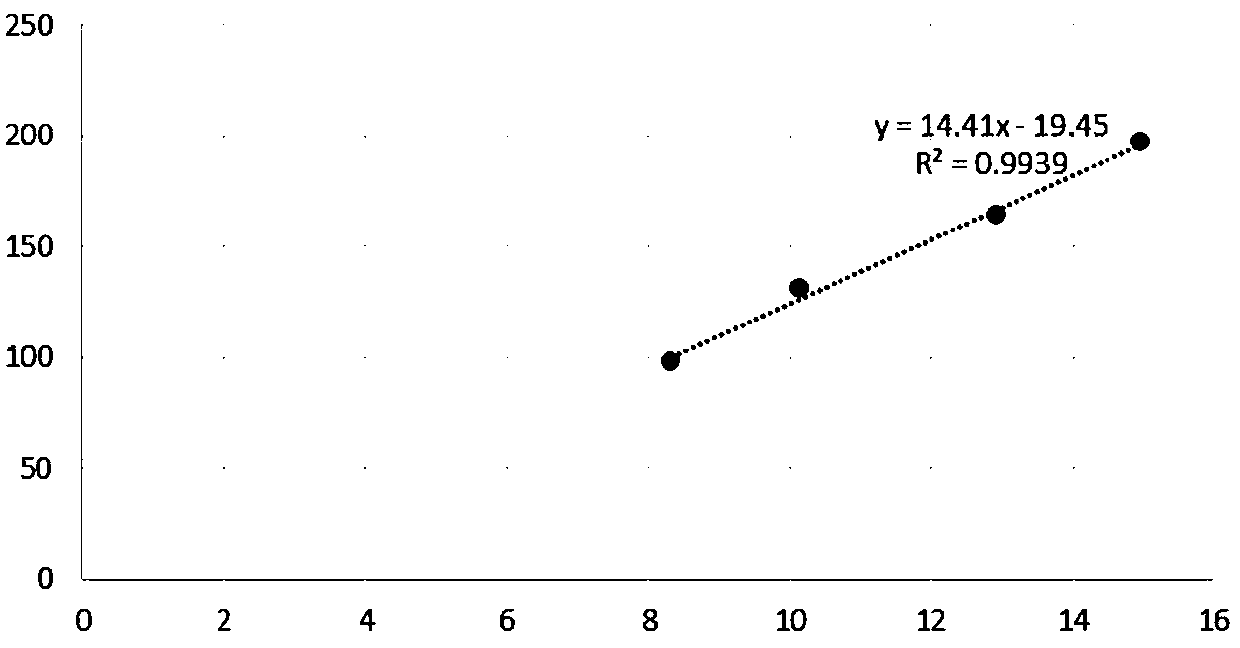

[0057] S3. With the light intensity as the ordinate and the area of the Mura area as the abscissa, multiple data points are used for linear regression fitting to obtain the first linear relationship curve between the light intensity and the area of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com