Simplified fly eye type light beam homogenizer

A homogenizer and simplification technology, applied to lasers, laser parts, instruments, etc., can solve the problems of large loss of light energy and difficult processing, and achieve the effect of simplifying the structure and overcoming the difficulties in processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

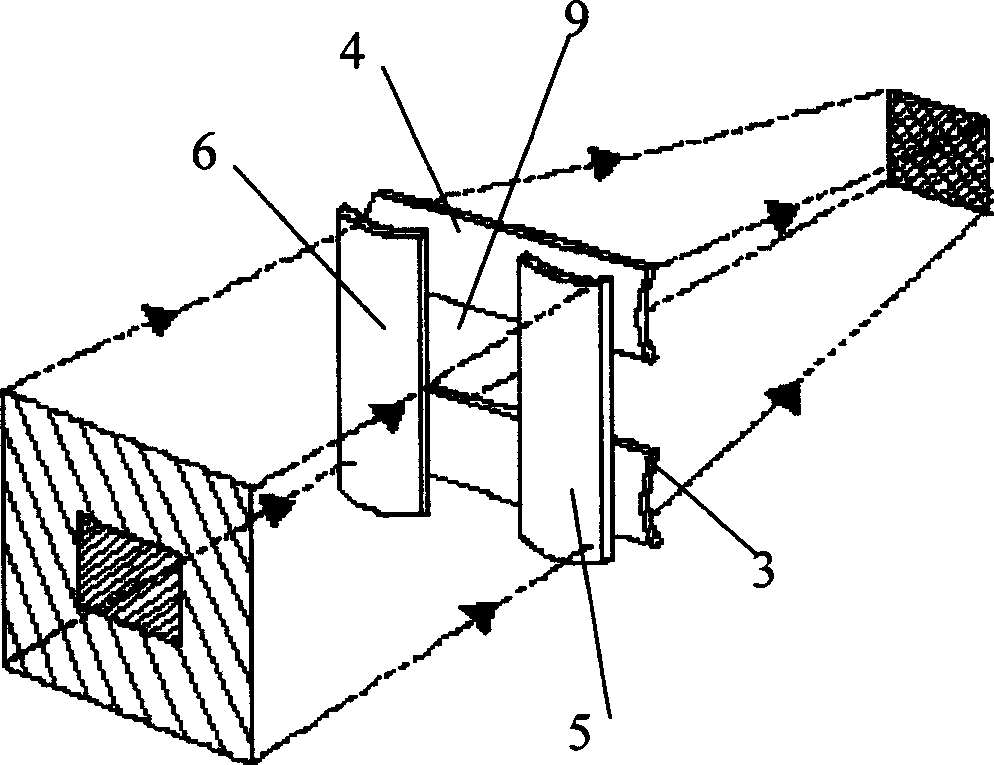

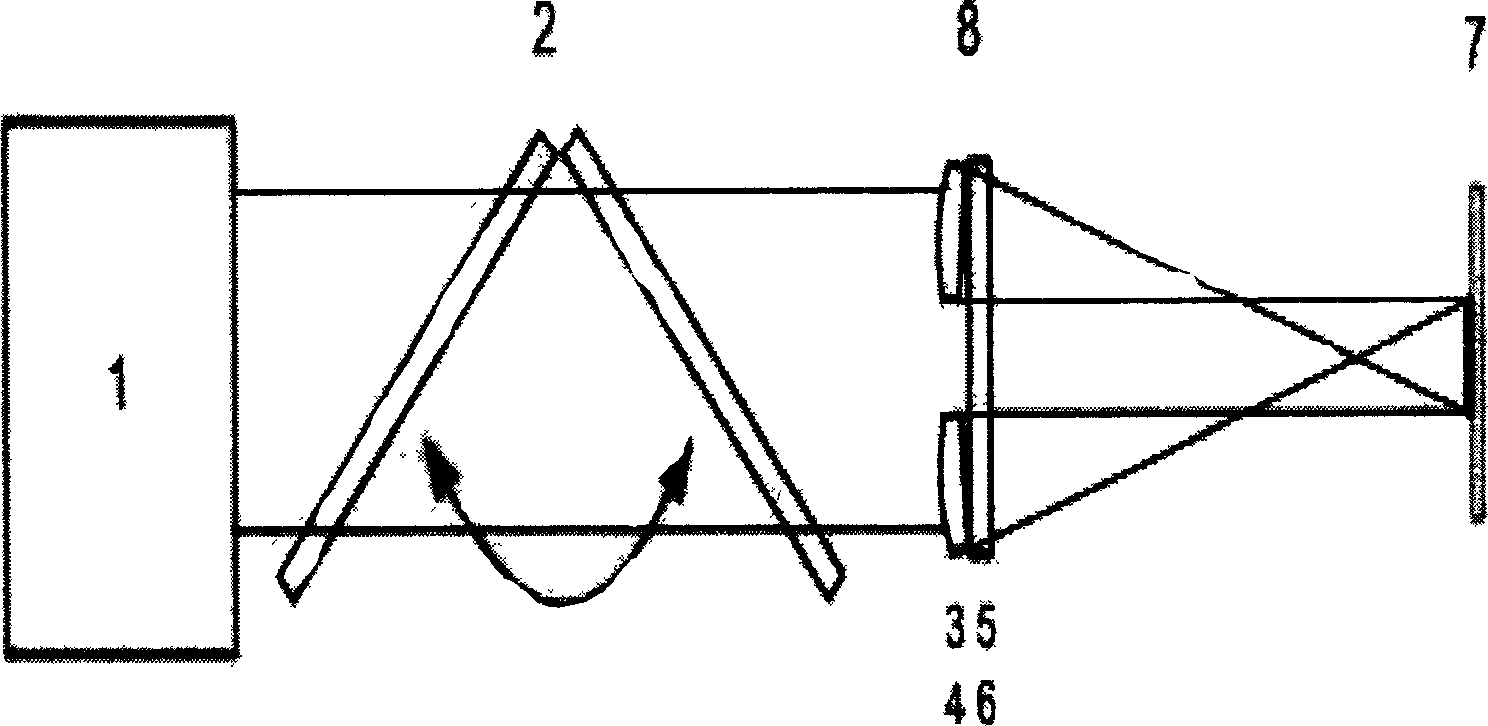

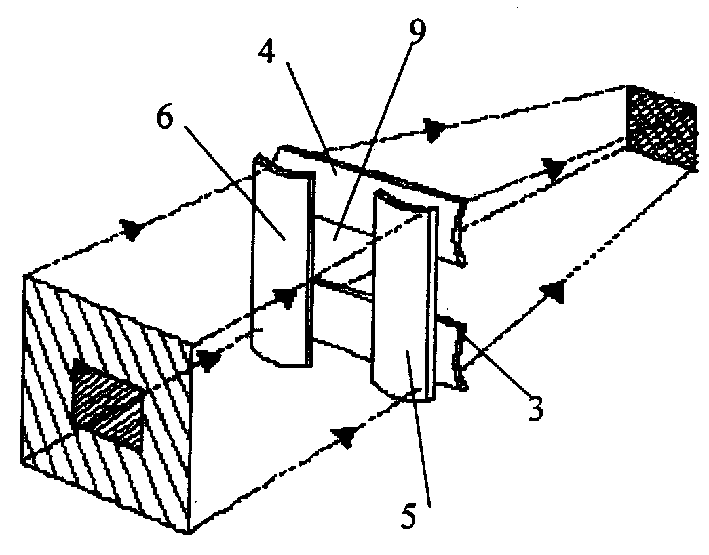

[0009] see figure 1 with figure 2 , figure 1 It is a structural principle diagram of a simplified fly-eye beam homogenizer of the present invention, figure 2 It is a schematic diagram of the optical path in the use state of the present invention. It can be seen from the figure that the simplified fly-eye beam homogenizer of the present invention is composed of two groups of quartz cylindrical mirrors 3, 4, 5, and 6 whose busbars are perpendicular to each other to form a 3*3 fly-eye lens array. The central part 9 is a square or rectangular hollow, and the light-receiving width of the cylindrical mirror and the width of the central hollow form three equal parts in the horizontal and vertical directions respectively.

[0010] The optical path of the present invention's use state is as figure 2 shown. The output laser light from the laser 1 is attenuated by the attenuator 2 and then enters the homogenizer 8 composed of four cylindrical mirrors 3, 4, 5, 6, and a uniform lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com