Method for manufacturing polysilicon of thin-film transistor

A technology of thin-film transistors and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve the problems of high crystallization rate, poor stability, and inconsistent characteristics of polysilicon layer components in the excimer laser annealing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

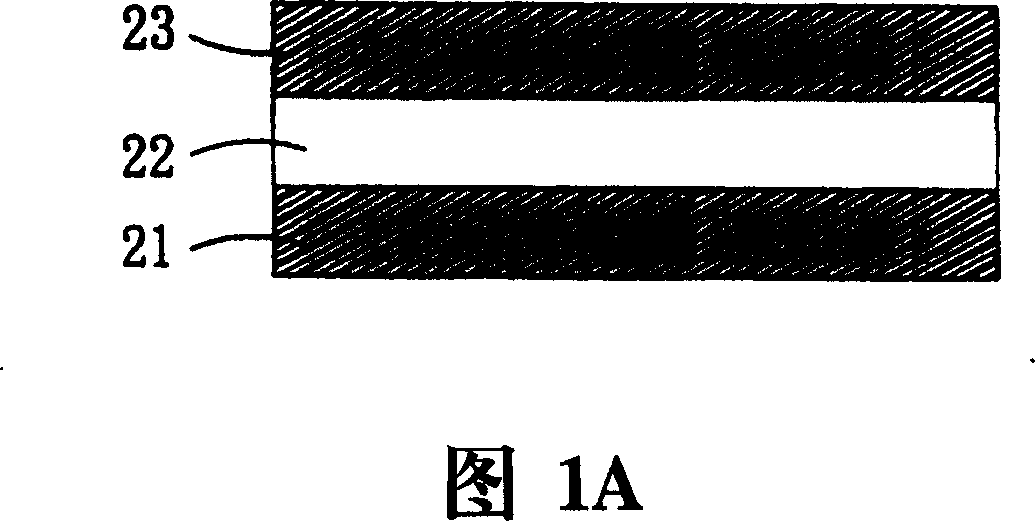

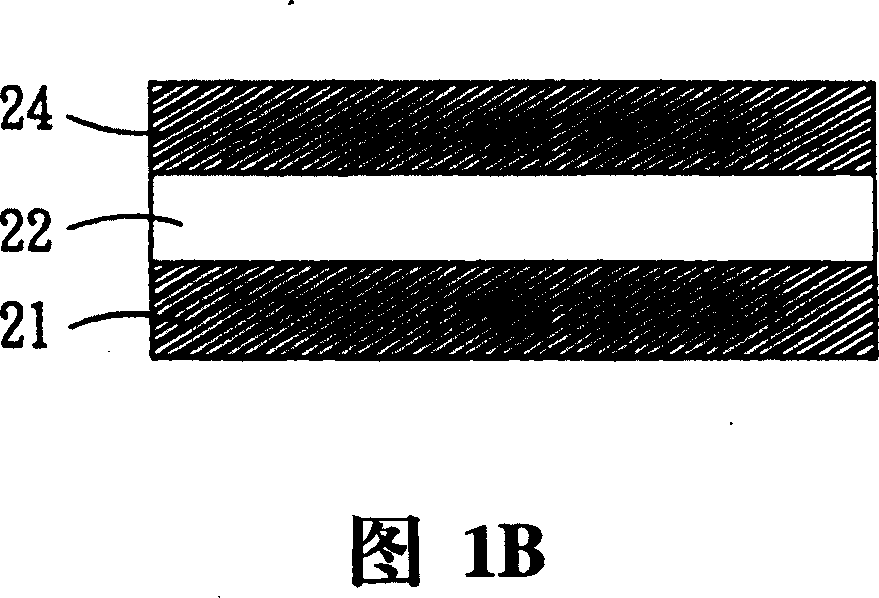

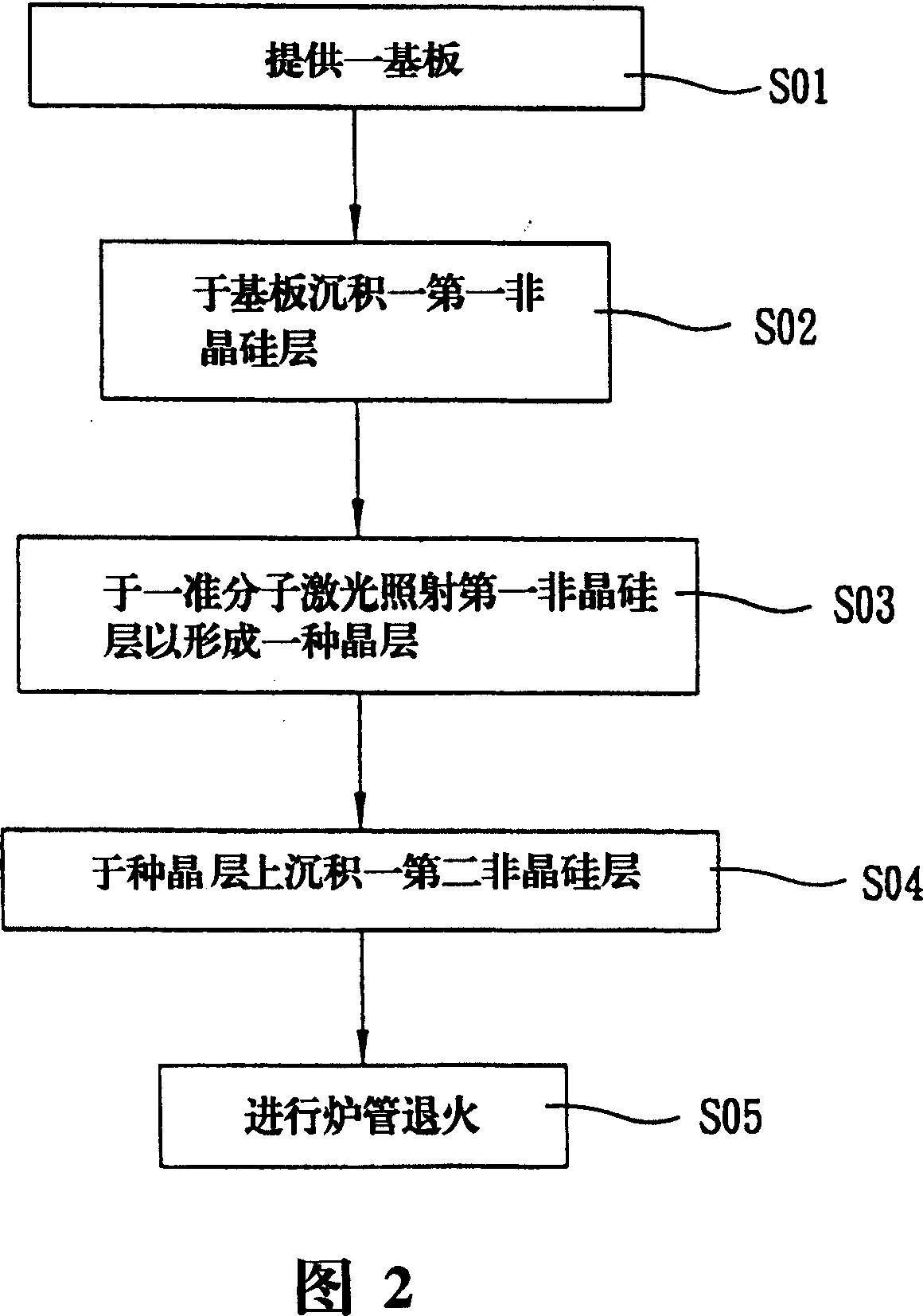

[0032] The polysilicon manufacturing method of the thin film transistor according to the preferred embodiment of the present invention will be described below with reference to the related drawings, wherein the same elements will be described with the same reference symbols.

[0033] As shown in FIG. 2, a polysilicon manufacturing method of a thin film transistor according to the first embodiment of the present invention includes the following steps: providing a substrate (S01); depositing a first amorphous silicon layer (S02) on the substrate; An excimer laser irradiates the first amorphous silicon layer to form a crystal layer (S03); deposits a second amorphous silicon layer on the seed layer (S04); and performs furnace tube annealing (S05).

[0034] As shown in FIG. 3A , a substrate 11 is provided in step 501 . Here, the substrate 11 can be a silicon substrate, a glass substrate or a plastic substrate. In this embodiment, a buffer oxide layer (Buffer oxide layer) 12 is for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com