Method for quickly erasing and writing conductive PVDF (Polyvinylidene Fluoride) layer through water film

A polyvinylidene and conductive layer technology is applied in the field of laser irradiation modification technology and conductive polymer material preparation, which can solve problems such as a large number of wastes or substandard products, increase manufacturing cost, waste, etc., and achieve simple operation and quick cleaning. Write, repeat and control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

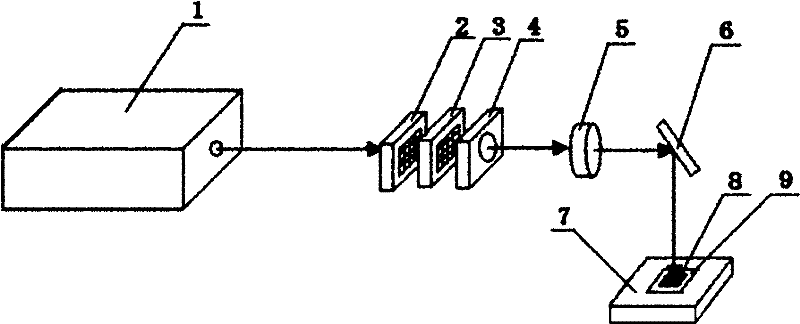

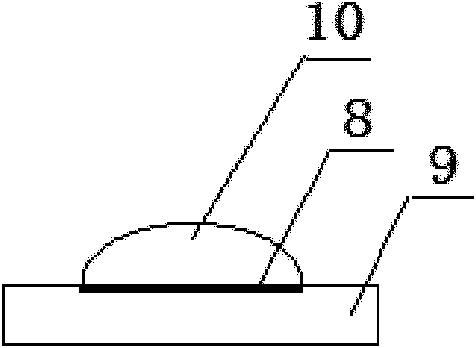

[0022] Such as figure 1 As shown, in the excimer laser irradiation system, the beam emitted by the KrF excimer laser 1 passes through the first-stage fly eye 2, the second-stage fly-eye lens 3, the first-stage objective lens 4, the second-stage objective lens 5, and the reflector 6 in turn. The direct radiation cleaning operation is performed on the conductive layer 8 of the sample 9 under the water film 10 . In addition, the conductive layer of the sample selected in the embodiment is about 1 cm×1 cm.

[0023] This embodiment mainly operates according to the following steps:

[0024] Step 1: Adjust the spot size and position through the red laser. The area of the spot in the cleaning process must not be smaller than the area of the conductive layer. The recording spot area is 1.2cm×1.2cm.

[0025] Step 2: Attach pure water droplets to and cover the entire conductive layer through a glue dropper to form a water film with a thickness of about 0.2cm. At this time, the t...

Embodiment 2

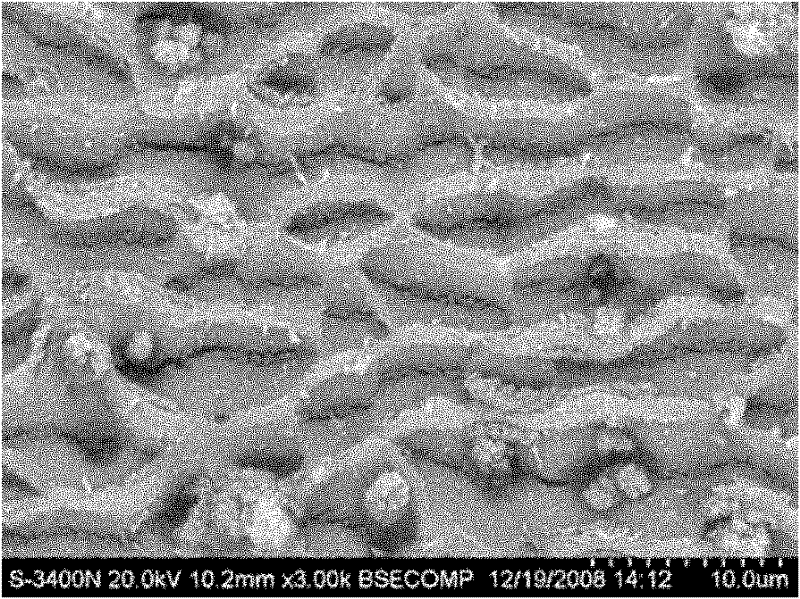

[0030] Embodiment 2 uses the same device and method as Embodiment 1, except that the laser output energy set in the third step of the operation step is 300 mJ. The surface microstructure of the material after removing the conductive layer is as follows: Figure 5 Shown: With the decrease of the output energy, the clearing time increases slightly, which is about 30 seconds; compared with Example 1, there are traces of the three-dimensional network structure, and the clearing effect is slightly weakened.

Embodiment 3

[0032] Embodiment 3 adopts the same device and method as Embodiment 1, except that the laser output energy set in the third step of the operation step is 200 mJ. The surface microstructure of the material after removing the conductive layer is as follows: Figure 6 Shown: With the decrease of the output energy, the clearing time increases slightly, which is about 40 seconds; compared with Example 1, the three-dimensional network structure leaves traces, and the clearing effect is slightly weakened.

[0033] All in all, the laser vaporization process using water film effectively removes the conductive layer of conductive polyvinylidene fluoride, and also realizes the reconstruction function of the conductive layer, which improves the laser preparation process of conductive polyvinylidene fluoride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com