Method for preparing magnetic function textile by utilizing quasi-molecule ultraviolet source

A UV light source and excimer technology, applied in textiles and papermaking, fiber type, fiber treatment, etc., can solve problems such as strength reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

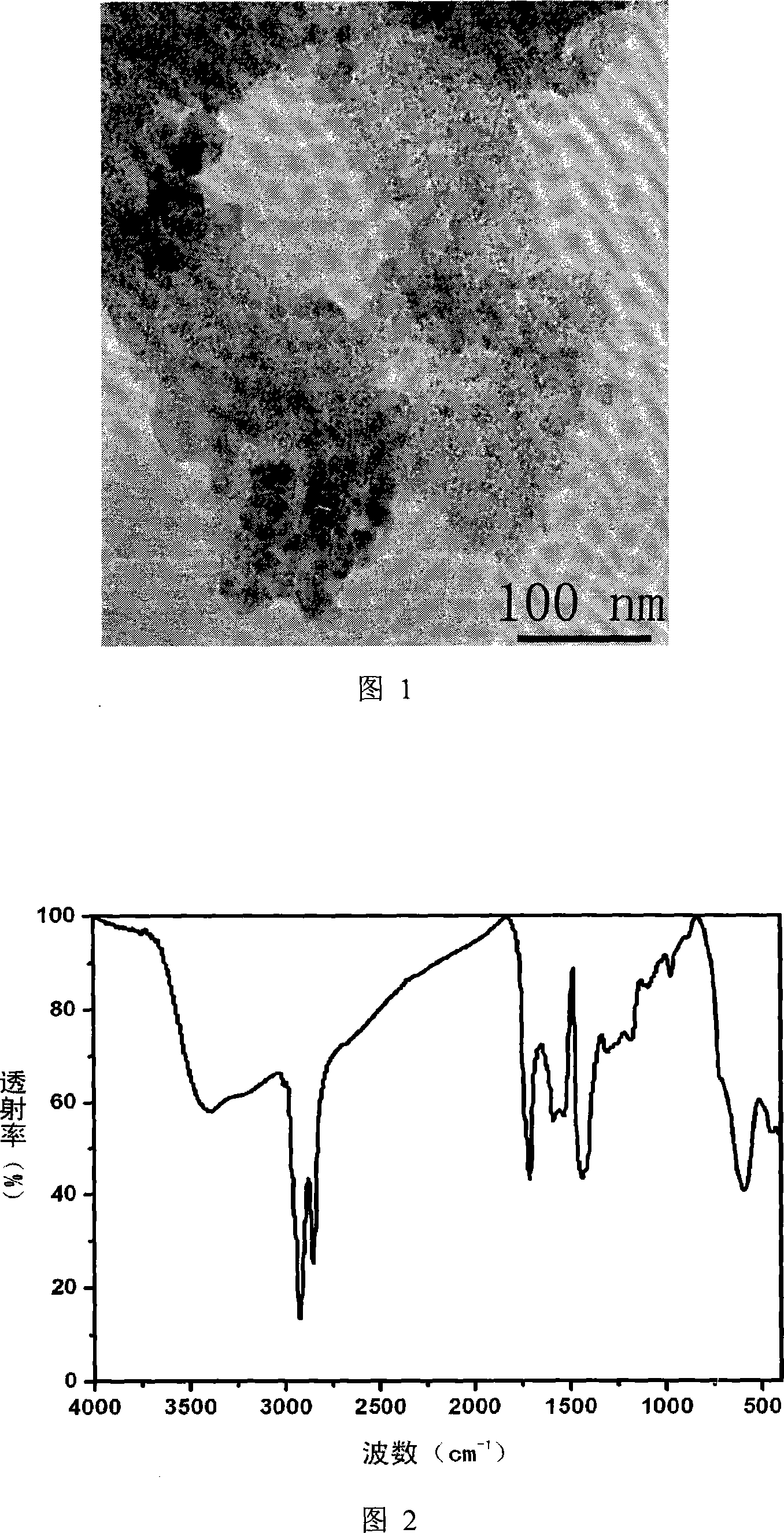

[0036] a) Weigh 2.51g (0.0093mol) FeCl 3 ·6H 2 O and 1.25g (0.0045mol) FeSO 4 ·7H 2 O was dissolved in 600ml of deionized water, and under the protection of nitrogen at room temperature, 24ml of ammonia water with a concentration of 1.5mol / l was added point by point to the above solution to obtain a black precipitate. The precipitate was washed 5 times with deionized water and ethanol by means of magnetic separation, the precipitate was dispersed in ethanol, 10.42g of oleic acid (equivalent to oleic acid of 10 times the precipitation mass) was added, and ultrasonic dispersion was carried out at 80°C for 30 minutes.

[0037] b) Using ethanol to wash away excess oleic acid with the help of magnetic separation, and transfer the modified nano ferroferric oxide particles into 100 ml of ethanol.

[0038] c) Immerse the polyester fabric in an ethanol solution containing nanometer ferroferric oxide particles modified with oleic acid on the surface for 1 min.

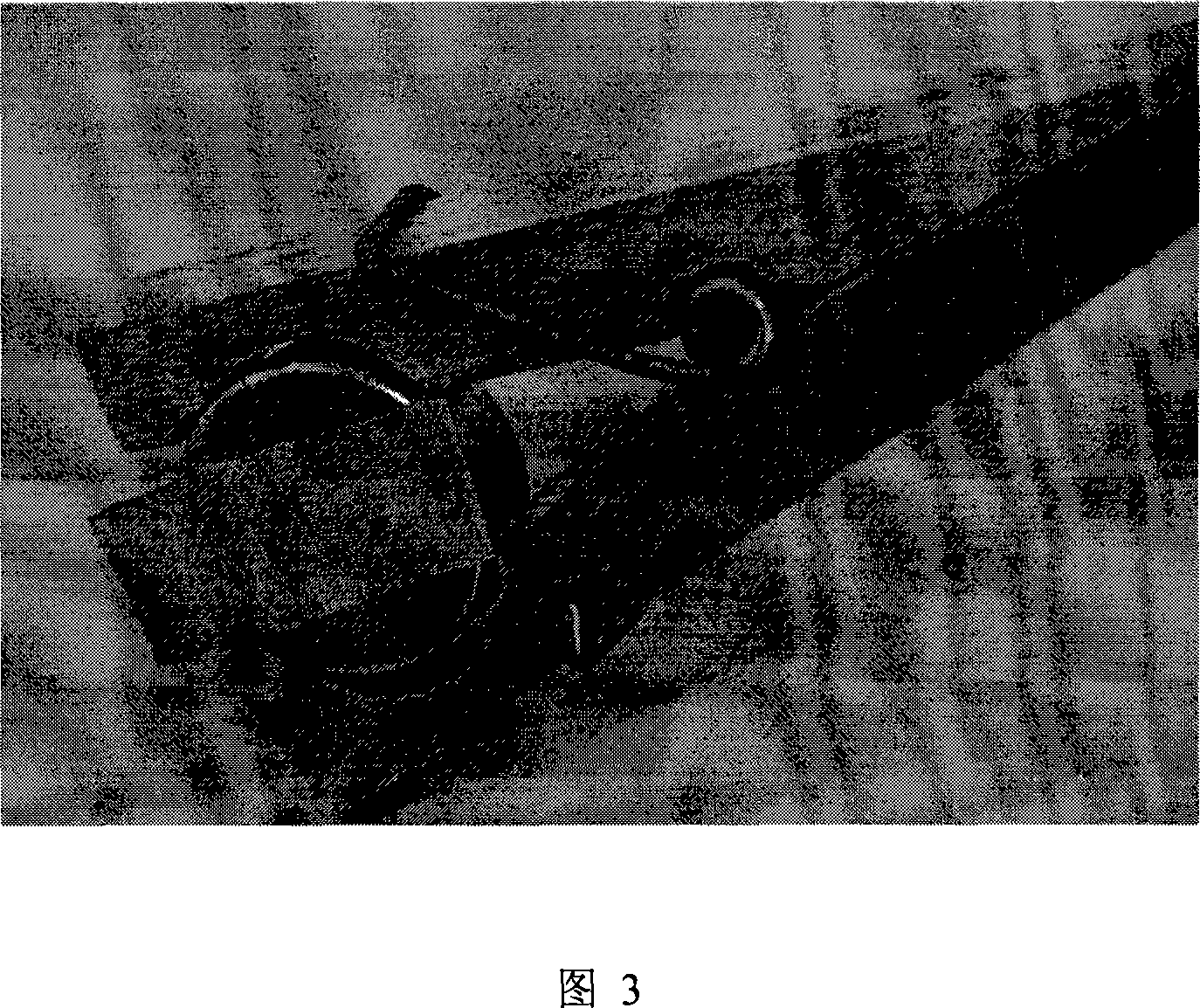

[0039] d) The 222nm excimer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com